Automatic chopped chilli processing equipment for food processing

An automatic processing and food processing technology, applied in food science, dissolution, grain processing, etc., can solve problems such as time-consuming and labor-intensive, inconvenient operation, and low efficiency of chili peppers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

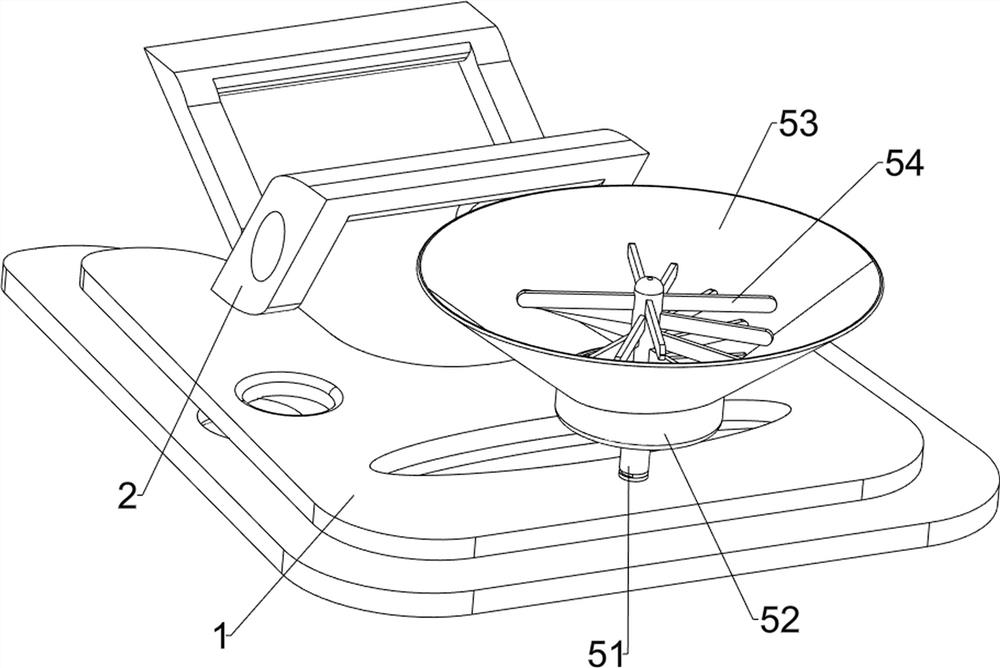

[0076]Automatic processing equipment for food processing, such asfigure 1 As shown, the base 1, the first bracket 2, the second bracket 3, the transmission mechanism 4, the rolling mechanism 5, and the reciprocating mechanism 6 are provided, and the base 1 is provided with a first bracket 2, and the lower side of the first bracket 2 is provided. There is a second bracket 3, and the first bracket 2 is connected between the top of the second bracket 3, and the base 1 is provided with a rolling mechanism 5 on the front seat 1, and a reciprocating mechanism 6 is provided on the transmission mechanism 4.

[0077]Artificial manual chili is less efficient, inconvenient operation and time consuming, this equipment can automatically pick pepper, high efficiency, convenient operation and saving time, first in the transmission 4, then put the pepper, then cause the transmission mechanism 4 to run The transmission mechanism 4 moves the pepper forward, and the transmission mechanism 4 drives the re...

Embodiment 2

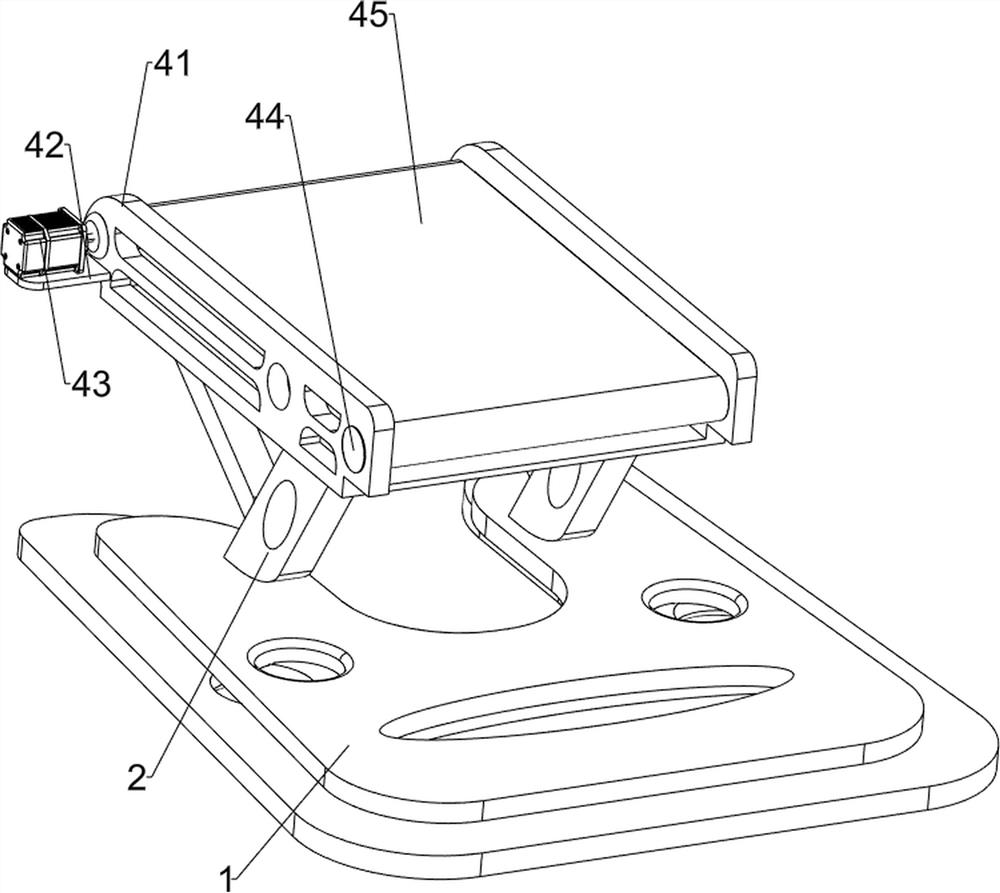

[0079]On the basis of Example 1, such asfigure 2 ,image 3 withFigure 4 As shown, the transmission 4 includes a gantry 41, a first fixing block 42, a motor 43, a drum 44, and a belt 45 having a gantry 41 between the top of the first bracket 2 and the second bracket 3, and the gantry 41 left The side rear portion is provided with a first fixing block 42, and a motor 43 is attached to the top of the first fixing block 42, and two rollers 44 are rotated between the left and right sides of the gantry 41, and the rear side drum 44 and the output of the motor 43 are provided. The shaft is connected, and the drum 44 on both sides of the front and rear is surrounded by a conveyor belt 45.

[0080]In the back of the belt 45, a pepper is placed on the back side of the conveyor, and the motor 43 is activated. The output shaft of the motor 43 rotates to rotate the rear side drum 44 to rotate, and the conveyor belt 45 is rotated, the conveyor belt 45 rotates the drum 44 to rotate the front side, and...

Embodiment 3

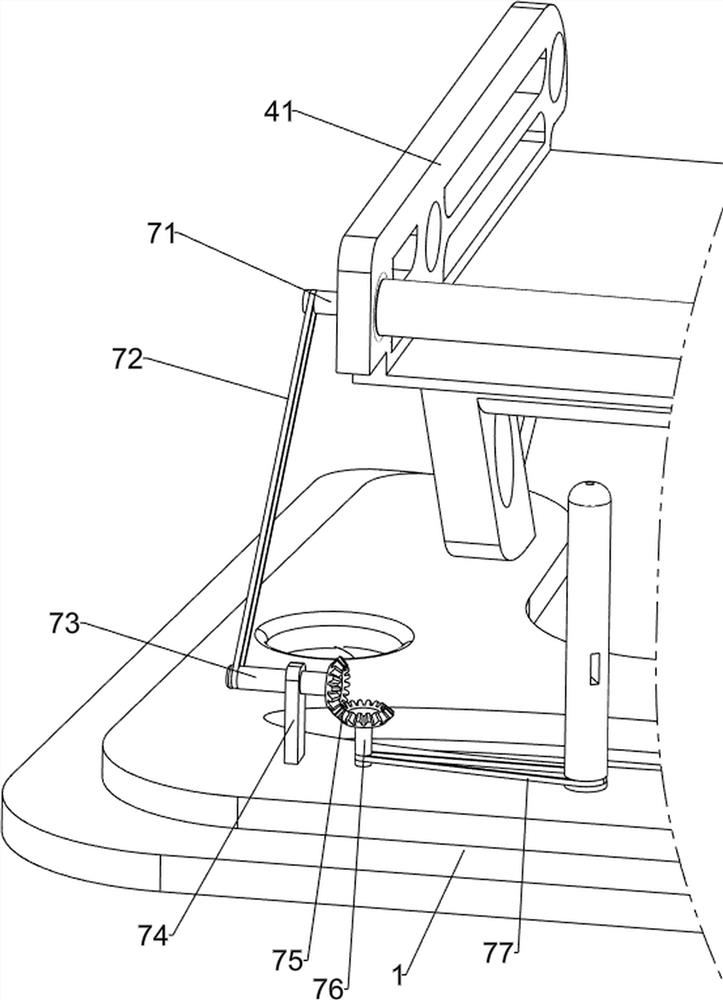

[0086]On the basis of Example 2, such asfigure 1 ,Figure 5 ,Figure 6 ,Figure 7 withFigure 8As shown, there is also an automatic rotating mechanism 7, the automatic rotation mechanism 7 includes a second rotating shaft 71, a first transmission assembly 72, a third rotating shaft 73, a second fixing block 74, a cone 75, a fourth rotation shaft. 76 and the second transmission assembly 77, the second rotating shaft 71 is provided on the left side of the drum 44, and the second fixing block 74 is provided on the front side on the front side, and the upper inner direction of the second fixed block 74 is provided. The three-rotating shaft 73, the left side of the second rotating shaft 71 and the left side of the third rotation shaft 73 are connected between the first transmission assembly 72, and the left rotation of the front side on the front side is provided with the fourth rotation shaft 76, fourth rotation. The upper portion of the shaft 76 is provided with a taper gear set 75, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com