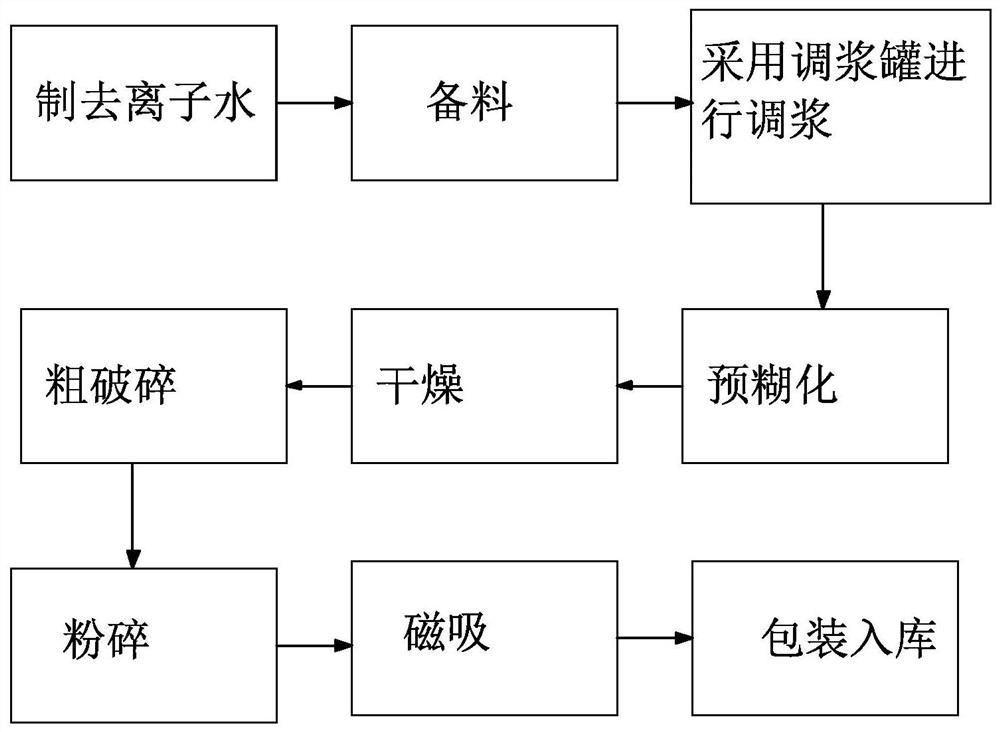

High-puffing waxy corn pre-gelatinized starch suitable for fishskin peanuts and equipment thereof

A technology of waxy corn starch and pregelatinized starch, which is applied in the food field, can solve problems such as single taste, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

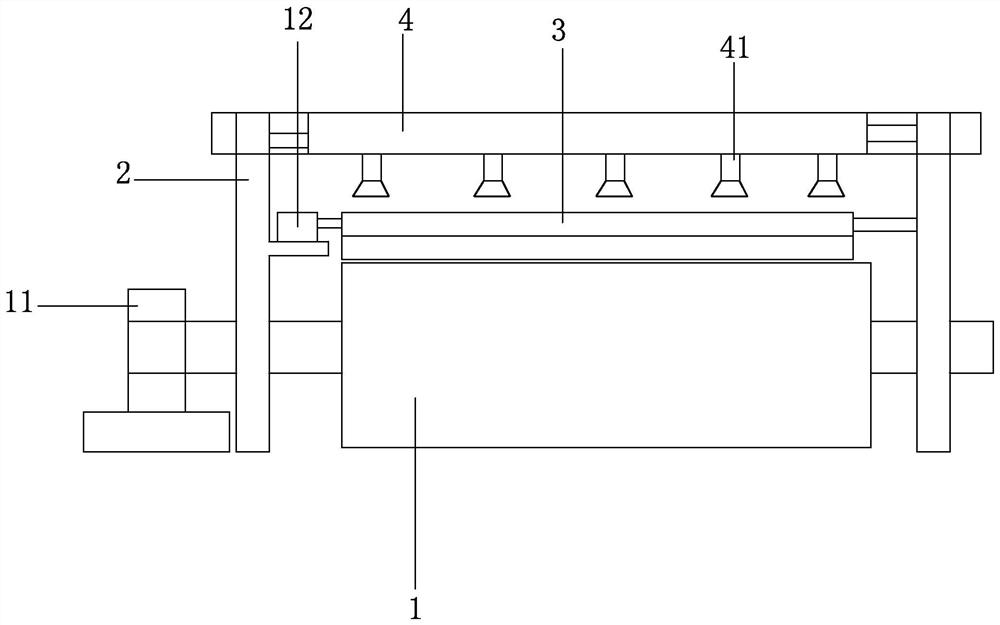

[0032] refer to Figure 1 to Figure 3 Embodiments of the present invention will be further described.

[0033] Single drum pregelatinization machine: including frame 2, drum 1 and crusher, drum 1 and frame 2 are connected in rotation, the crusher is set on frame 2 and placed on the path of drum 1 rotation, and one end of drum 1 has A motor 11 that drives its rotation.

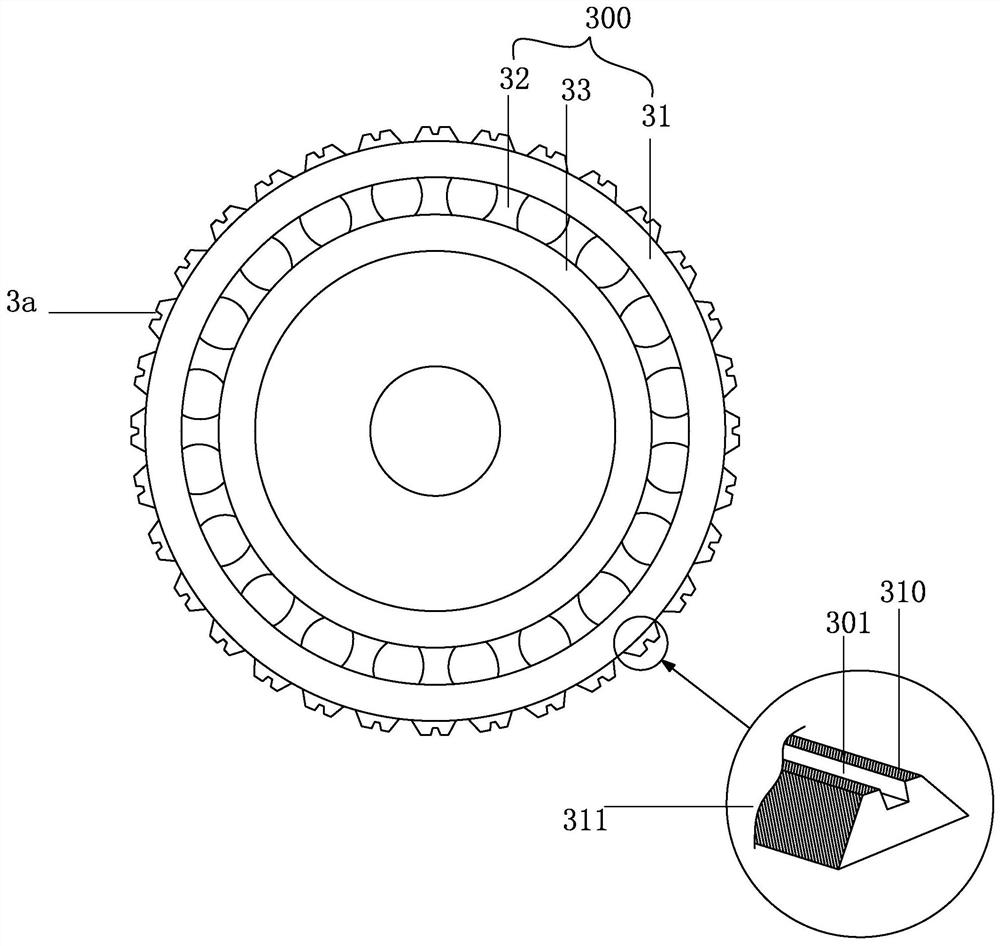

[0034] The crusher includes: a motor 12 providing driving force; a main shaft controlled by the motor 12 to rotate; a crushing assembly 3 for crushing the gelatinized starch on the surface wall of the rotating drum 1 .

[0035] The crushing assembly includes a force applying unit 300 for crushing the gelatinized starch on the surface wall of the rotary drum 1, and also includes an air duct 4 for blowing the crushed gelatinized starch.

[0036] The air duct 4 is provided with a blower fan for heating the air duct, and the air duct has several branch pipes 41, and the branch pipes have air outlets.

[0037] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com