Automatic real stone paint production equipment

A kind of production equipment and technology of real stone paint, applied in the field of real stone paint, can solve the problem of high cost and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

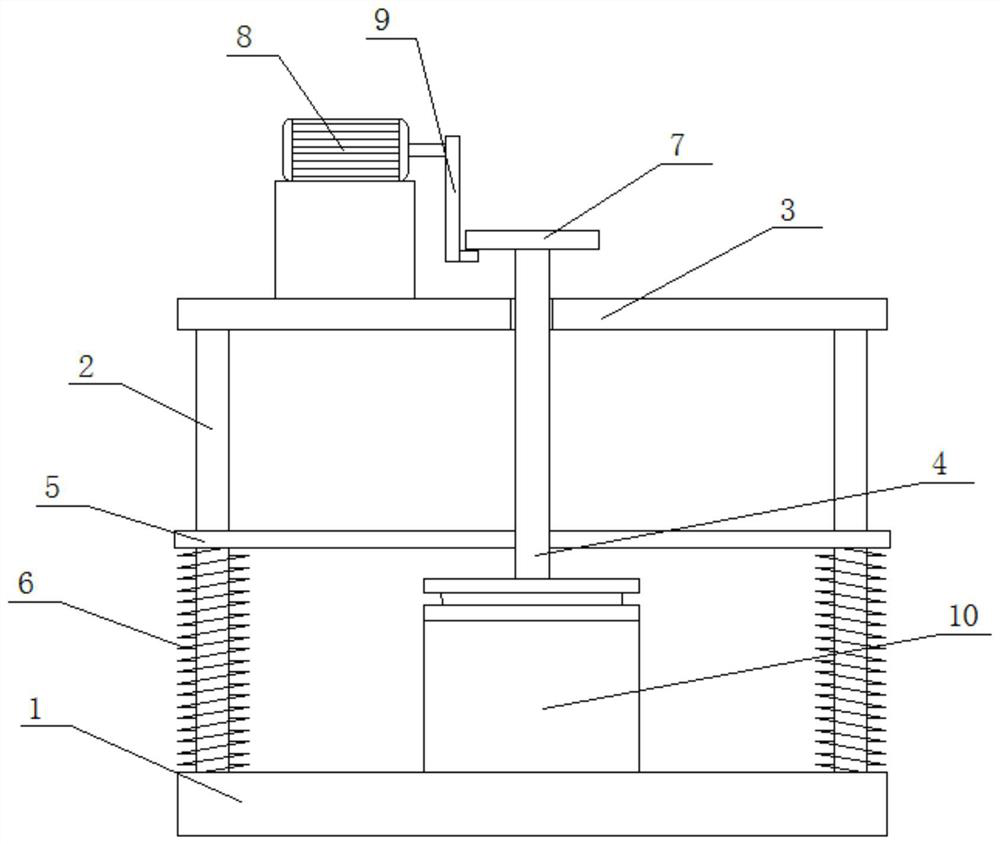

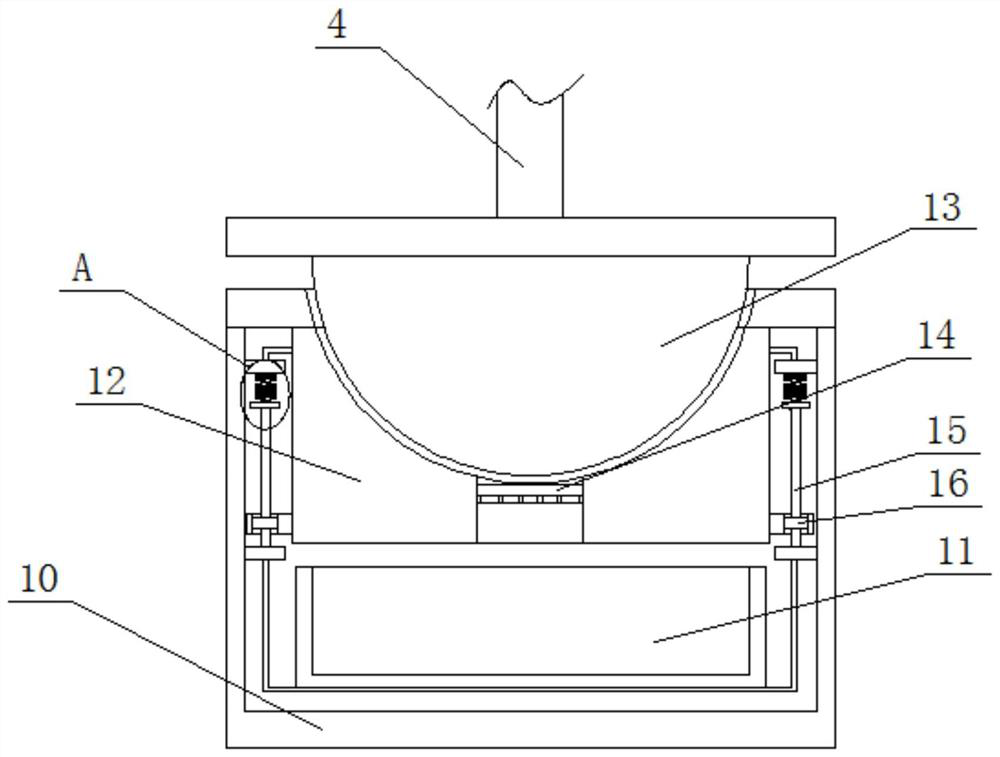

[0023] refer to Figure 1-5 , an automatic real stone paint production equipment, including a base 1, two uprights 2 are symmetrically and fixedly installed on the top of the base 1, and the same horizontal plate 3 is fixedly installed on the top of the two uprights 2, and the horizontal plate 3 is slidably connected with a connection Rod 4, the bottom end of connecting rod 4 extends to the below of horizontal plate 3 and is fixedly installed with hammer head 13, and the top of base 1 is fixedly installed with processing box 10, and is slidingly connected with placing seat 12 in processing box 10, and placing seat 12 The top is provided with a spherical groove, and the bottom of the hammer head 13 extends into the spherical groove, and the bottom inner wall of the spherical groove is provided with a feeding hole, and a screen 14 is fixedly installed in the feeding hole, and the bottom of the screen 14 A steel bar grid is fixedly installed, and the steel bar grid is fixedly con...

Embodiment 2

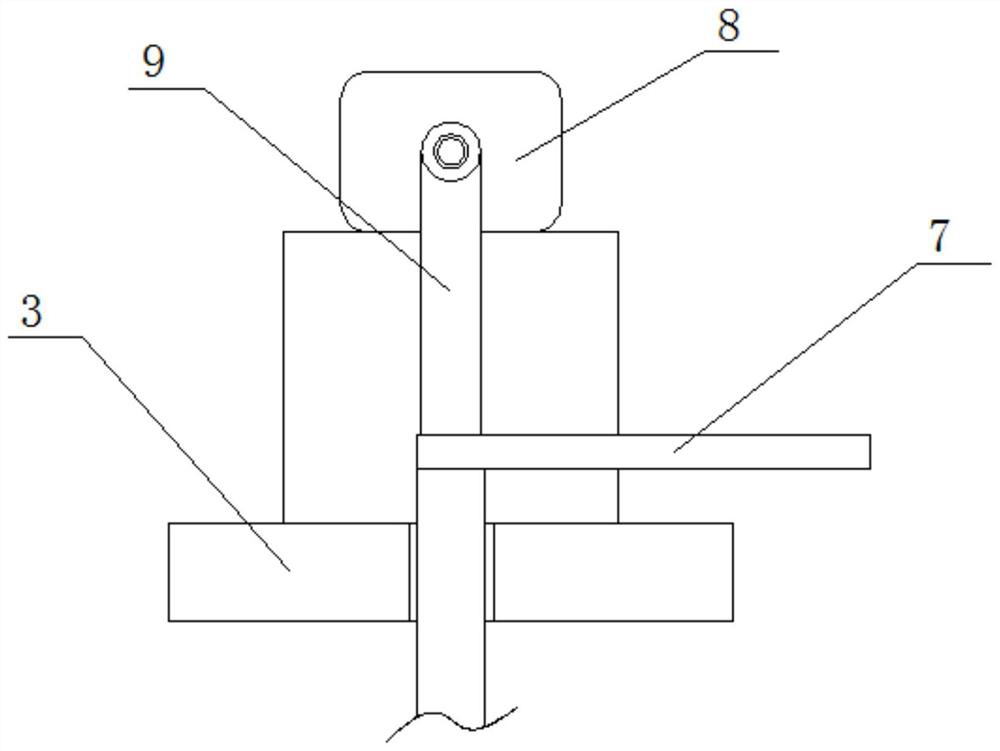

[0025] In the present invention, a rotating rod 9 is fixedly installed on the output shaft of the driving motor 8, and a lifting shaft is fixedly installed at the bottom of one side of the rotating rod 9, and the top of the connecting rod 4 extends to the top of the horizontal plate 3 and is fixedly installed with a connecting plate 7 , the lifting shaft is in movable contact with the bottom side of the connecting plate 7, and the lifting shaft is movably connected with the connecting plate 7 to facilitate driving the hammer head 13 to perform free fall motion.

[0026] In the present invention, the limit rod 5 is slidably connected to the column 2, and one end of the two limit rods 5 close to each other is fixedly connected to the connecting rod 4, and the column 2 is sleeved with a tension spring 6, and the tension spring 6 is located at Below the limiting rod 5, the top and bottom ends of the tension spring 6 are fixedly connected with the bottom of the limiting rod 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com