Pipe mechanical cutting equipment for civil engineering

A technology of mechanical cutting and civil engineering, applied in metal processing equipment, metal processing machinery parts, shearing machine equipment, etc., can solve the problems of dust accumulation, easy to pollute the air and the environment, achieve a wide range of dust collection, and ensure the dust collection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

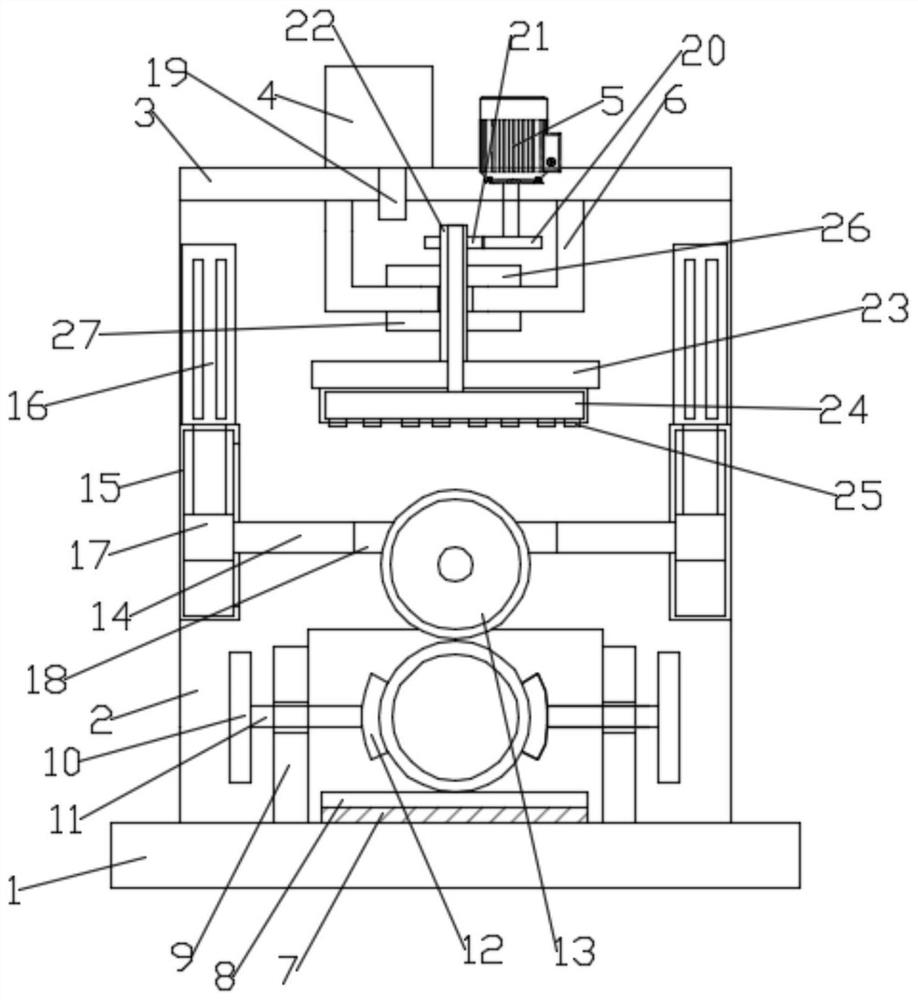

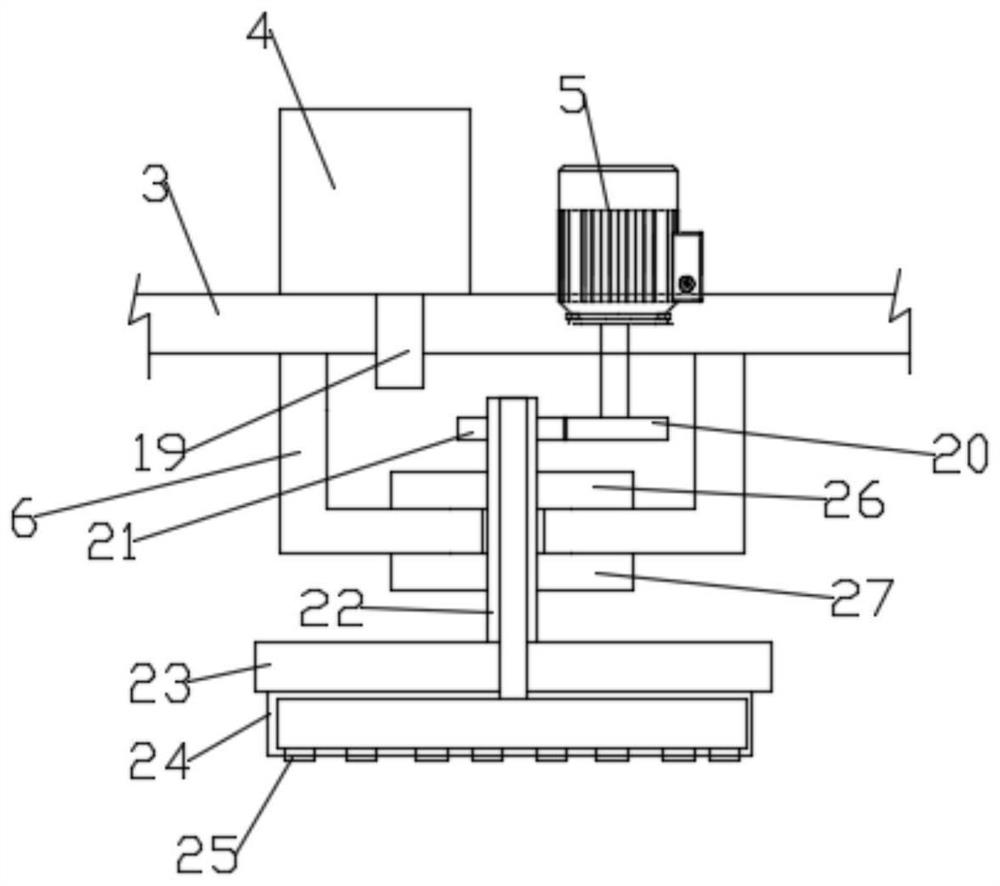

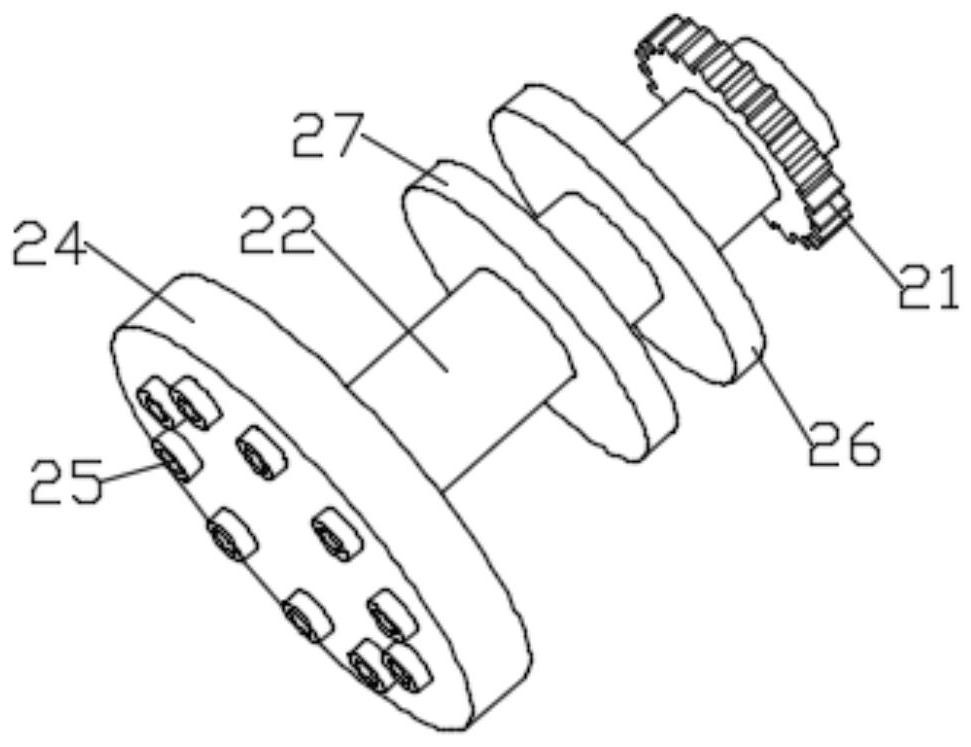

[0025] Such as figure 1 and Figure 4 As shown, in the embodiment provided by the present invention, a mechanical cutting equipment for civil engineering pipe fittings includes a base 1, and the upper surfaces of the front and rear sides of the base 1 are fixedly equipped with supporting backboards 2, and the supporting backboards The top of the 2 is fixedly installed with a supporting top beam 3, and a dust suction mechanism is arranged on the supporting top beam 3; a lifting assembly for adjusting the height of the lifting crossbeam 14 is arranged at the middle of the supporting backboard 2, and the lifting crossbeam 14 is provided with a cutting assembly; the lifting beam 14 is provided with a strip channel 18, the cutting assembly includes a cutting disc 13 that is rotated in the strip channel 18, and the cutting assembly also includes a drive for driving The cutting motor 28 that the strip channel 18 rotates, the cutting motor 28 is fixedly installed on the lifting beam ...

Embodiment 2

[0029] Such as figure 1 and Figure 4 As shown, in the embodiment provided by the present invention, a mechanical cutting equipment for civil engineering pipe fittings includes a base 1, and the upper surfaces of the front and rear sides of the base 1 are fixedly equipped with supporting backboards 2, and the supporting backboards The top of the 2 is fixedly installed with a supporting top beam 3, and a dust suction mechanism is arranged on the supporting top beam 3; a lifting assembly for adjusting the height of the lifting crossbeam 14 is arranged at the middle of the supporting backboard 2, and the lifting crossbeam 14 is provided with a cutting assembly; the lifting beam 14 is provided with a strip channel 18, the cutting assembly includes a cutting disc 13 that is rotated in the strip channel 18, and the cutting assembly also includes a drive for driving The cutting motor 28 that the strip channel 18 rotates, the cutting motor 28 is fixedly installed on the lifting beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com