A tire packaging machine

A packaging machine and tire technology, applied in the engineering field, can solve the problems of single function and low efficiency, and achieve the effect of convenient collection and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

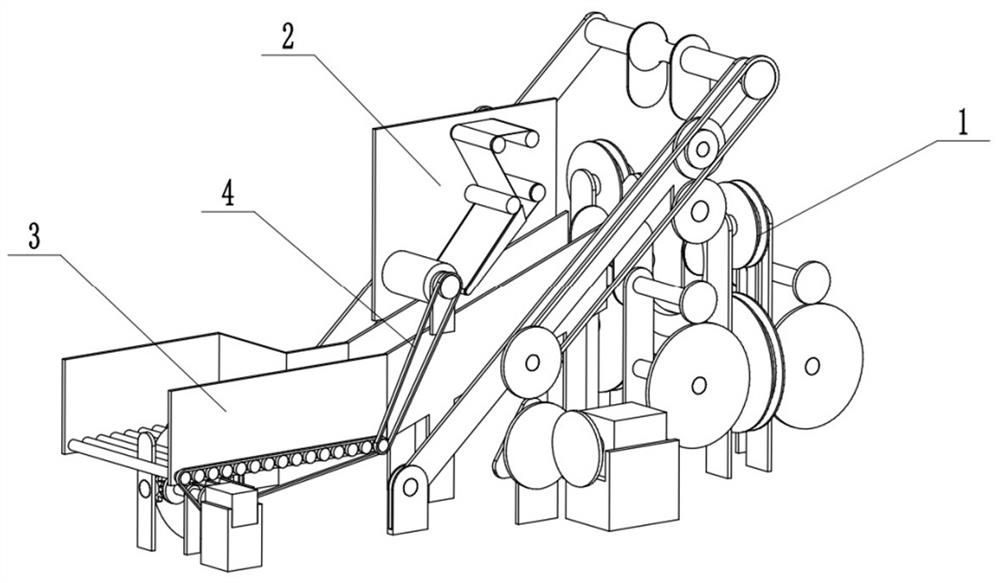

[0027] Bonded below Figure 1-11 In the present embodiment, a tire packaging machine includes a tire wrap device 1, a labeling device 2, a transfer device 3, a belt one 4, and the labeling device 2 is connected to the transfer device 3, and the labeling device 2 and the belt one. 4 is connected, the transfer device 3 is connected to the belt one 4.

specific Embodiment approach 2

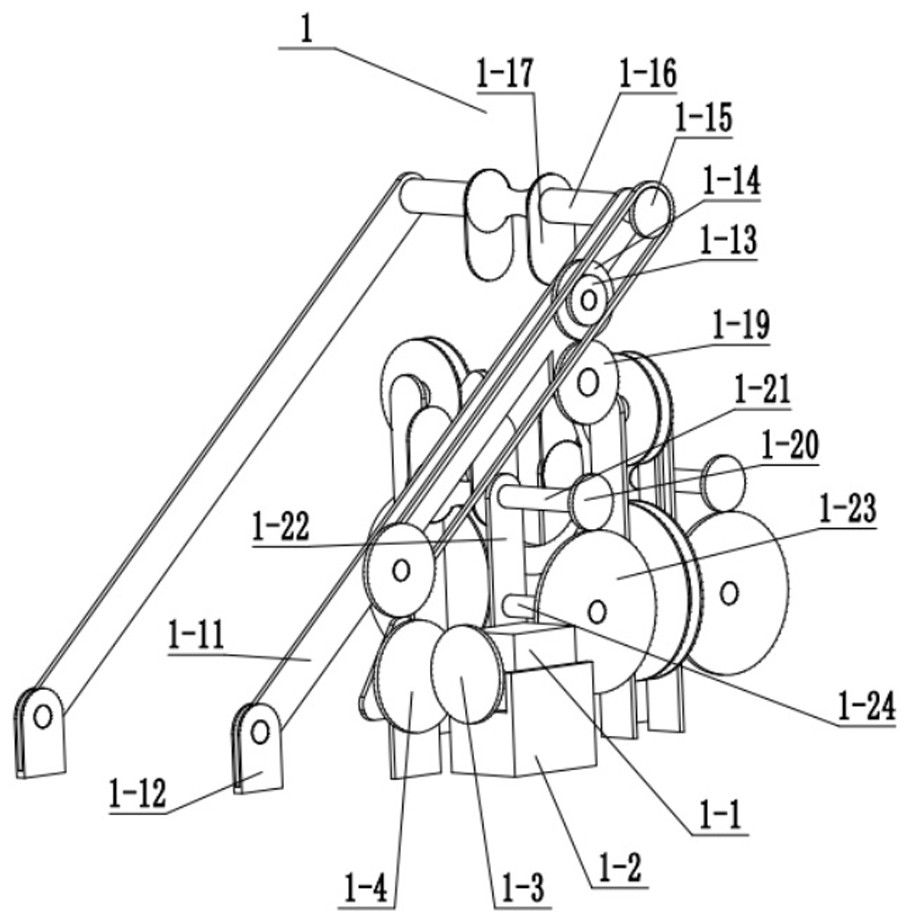

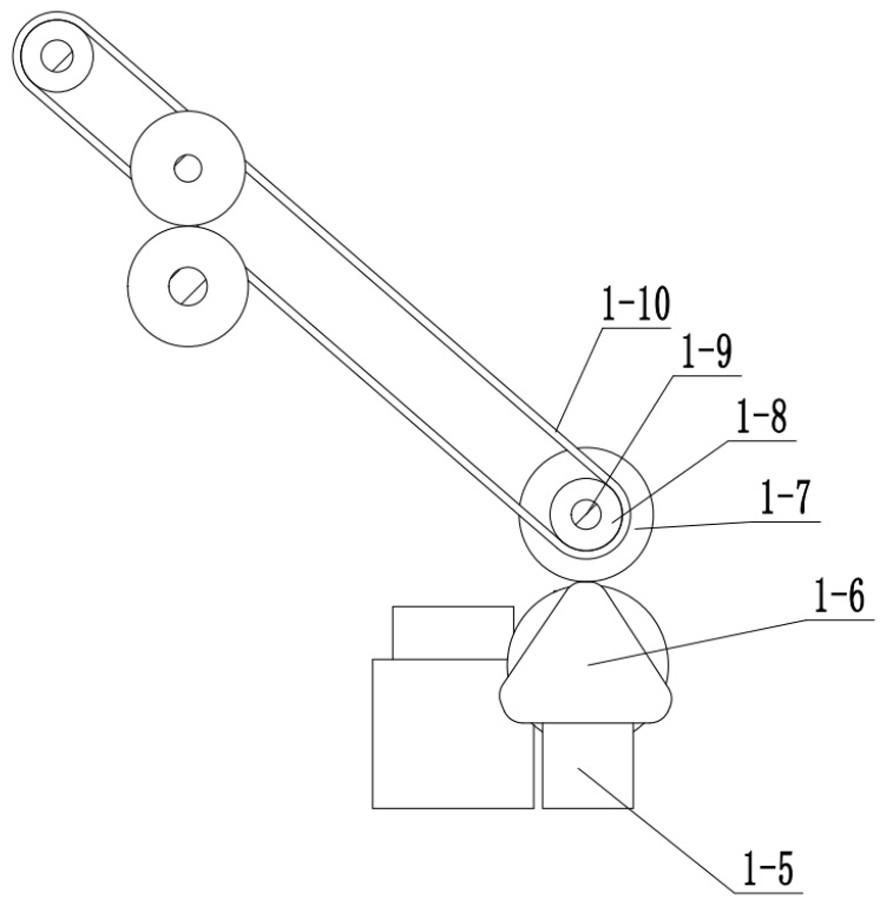

[0029] Bonded below Figure 1-11In the present embodiment, the present embodiment will further explain the embodiment, including a motor 1-1, a motor base 1-2, a runner 1-3, a runner 2-4, a bracket 1-5, a shaped wheel 1-6, runner three 1-7, small wheel three 1-8, small cylinder 1-9, belt 2 1-10, long arm 1-11, pedici 1-12, small Wheel four 1-13, runner four 1-14, runner five 1-15, outer tube one 1-16, fixed plate 1-17, upper fixed wheel 1-18, turn ram six 1-19, runner Seven 1-20, connecting column 1-21, stent three 1-23, connecting column 2 1-24, inner tube 1-25, lower fixed wheel 1-26, fixed plate 2 1-27, outer tube two 1-29, runner nine 1-30, connecting column 10 1-31, inner tube three 1-32, bracket 4 1-33, outer tube three 1- 34, fixed plate three 1-35, lower fixed wheel two 1-36, belt three 1-37, belt four 1-39, belt five 1-40, bracket six 1-41, tape volume 1 -42, functional ring 1-43, circle slot 1-44, small cylindrical 2 1-45, runner eleven 1-46, runner 12 1-47, runner thirte...

specific Embodiment approach 3

[0032] Bonded below Figure 1-11 In this embodiment, the present embodiment will further explain the embodiment, and the labeling device 2 includes a slide 2-1, a bracket 10-2, an output column 2-3, a fixed column 2-4, a fixed column 2-5, back to the roll 2-6, function block 2-7, trademark post 2-8, back plate 2-9, press wheel 2-10, bracket 11 2-11, runner twenty 2- 12, twenty-one 2-13, runner twenty two 2-14, belt 10 2-15, four brackets 10 2-2 are fixed with slide 2-1 fixed connection, output column 2-3, fixed Column 2-4, fixed column 2-5, return column 2-6 Return to the back plate 2-9, function block 2-7 fixed connection with the back plate 2-9, output column 2-3, fixed Pillar 2-4, fixed column 2-5, back roll column 2-6, function block 2-7 is connected to trademark 2-8, and the backplane 2-9 is rotated with the pressure sanner 2-10, Slide 2-1 is fixed to the back plate 2-9, the bracket 11 2-11 is fixedly connected to the slide 2-1, and the press wheel 2-10 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com