Atomic layer deposition equipment and processing method capable of reducing precursor deposition

A technology of atomic layer deposition and precursors, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve problems such as time-consuming and labor-intensive, cleaning costs, and production line production efficiency decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail by means of the following specific embodiments and accompanying drawings, as follows.

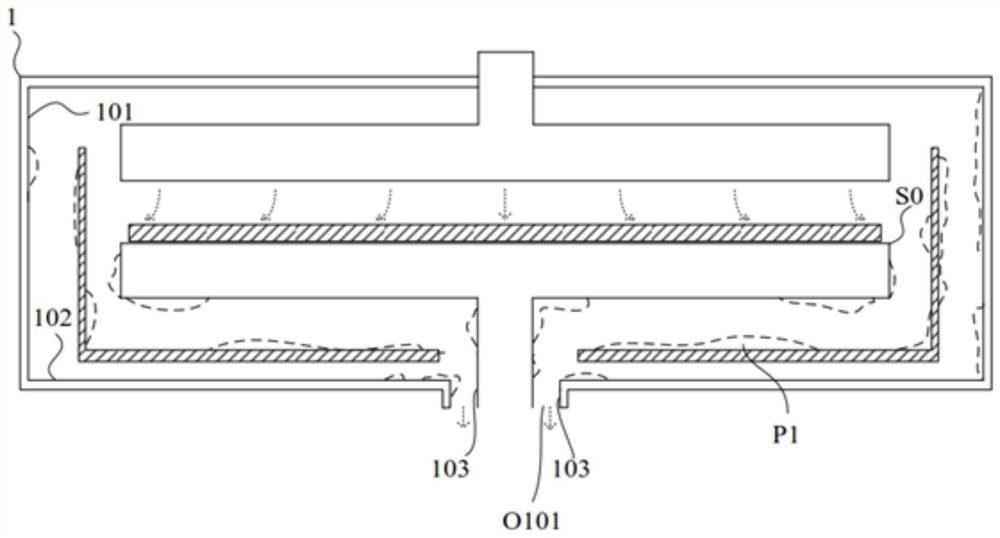

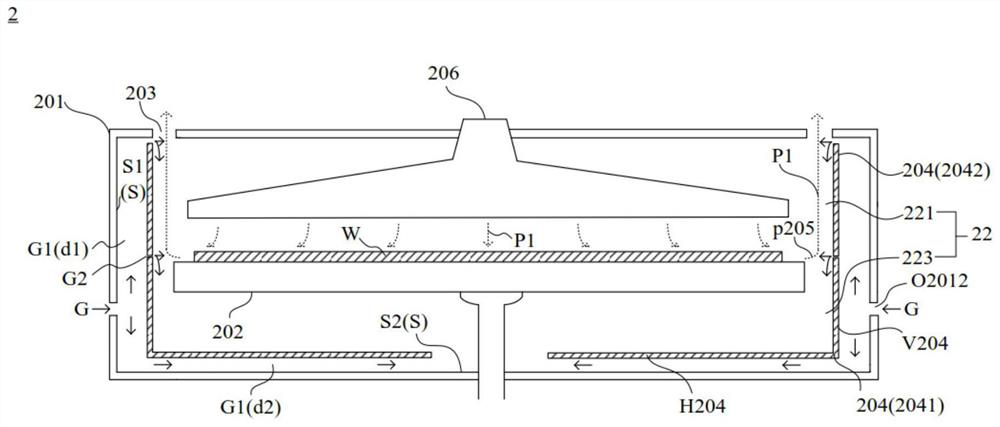

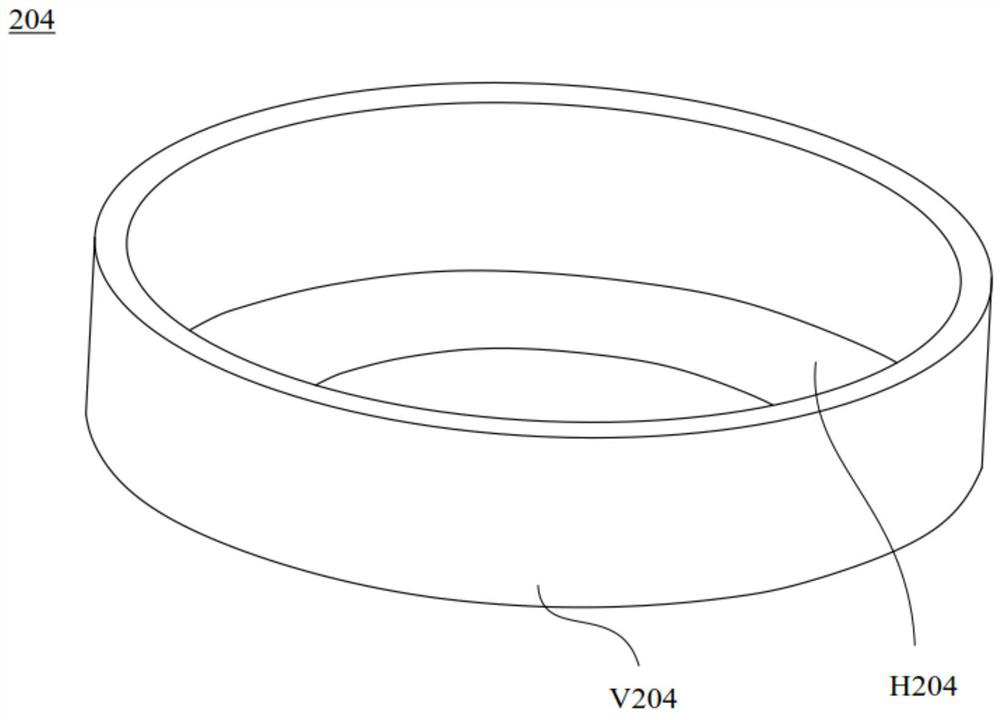

[0029] The present invention provides an atomic layer deposition device, which includes a cavity, a supporting device, a shield, at least one air inlet and at least one air inlet, and may further include a shield and a spray head, wherein the shield is arranged on the inner surface of the chamber (for example, the inner wall surface or the inner bottom surface of the cavity), and there is a first passage between the inner wall surface of the cavity. In the atomic layer deposition process, the precursor gas inlet can provide precursors, and the precursors can react with the substrate or the material on the surface of the substrate (eg, wafer), while the unreacted precursors will remain in the cavity.

[0030]The air inlet of the atomic layer deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com