Jaw locking type positive and negative rotation drill pipe

A forward and reverse, drill pipe technology, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve problems such as drill pipe thread tripping, achieve the effect of automatic loading and unloading, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

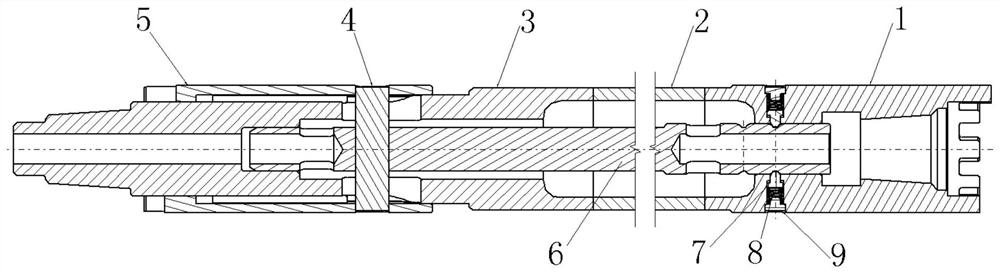

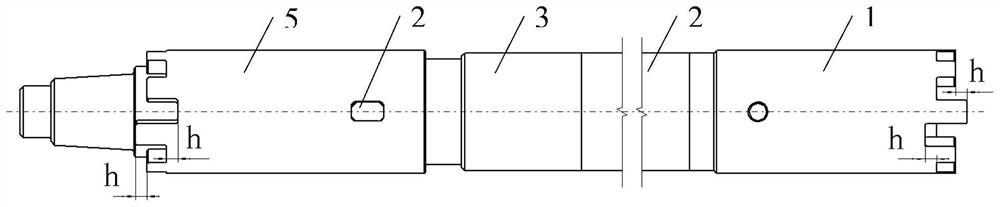

[0052] A kind of interlocking stop type forward and reverse drill pipe, such as Figure 1 to Figure 11 As shown, it includes a female joint 1, a rod body 2, a male joint 3, a rectangular pin 4, a sliding sleeve 5, a transmission rod 6, a positioning member 7, an elastic member 8 and a block 9, wherein the elastic member 8 is a spring.

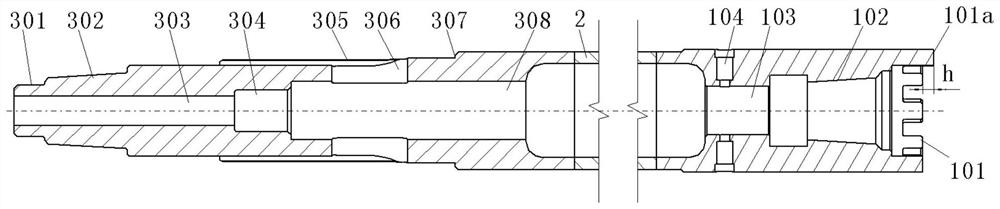

[0053] The female joint 1 and the male joint 3 are respectively connected with the rod body 2 through coaxial friction welding to form the drill pipe body. Such as image 3 shown.

[0054] (1) female connector 1

[0055] The wall thickness of the front end of the female joint is compatible with the rod body 2, so as to ensure an appropriate wall thickness of the friction welded pipe. The middle section is provided with a sliding hole 103 that cooperates with the transmission rod 6 , and two stepped limiting holes 104 are symmetrically provided on the wall of the sliding hole 103 for installing the positioning member 7 , the spring and the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com