Icing sensor based on optical fiber

A technology of icing sensors and optical fibers, applied in instruments, optical devices, measuring devices, etc., can solve the problems of destroying aircraft stealth performance and aerodynamic performance, high computational complexity, and affecting measurement accuracy, so as to avoid aircraft stealth performance and The effect of aerodynamic performance, simplification of complexity, and improvement of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

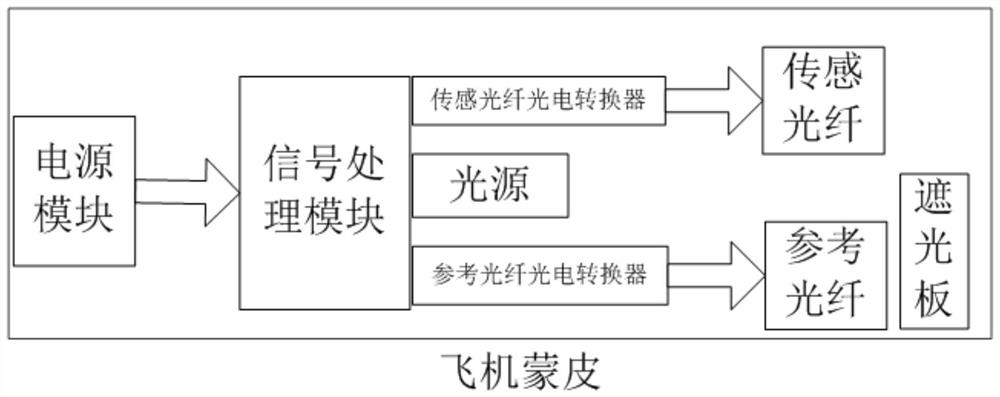

[0019] Example 1. A fiber optic based icing sensor constructed as figure 1 As shown, including a light source, a sensing fiber and a reference fiber are stacked in front of the light source, and a shading plate is arranged in front of the reference fiber; the rear ends of the sensing fiber and the reference fiber are respectively connected to a sensing fiber-optic photoelectric converter and a reference fiber-optic photoelectric converter. The converter, the sensing fiber optic converter and the reference fiber optic converter are all connected to the signal processing module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com