Method for testing resin curing shrinkage volume and fiber-resin contact angle

A technology of resin curing and testing method, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as easy generation of pores and decline in mechanical properties of composite materials, and achieve the effects of wide application, simple testing device, and high testing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

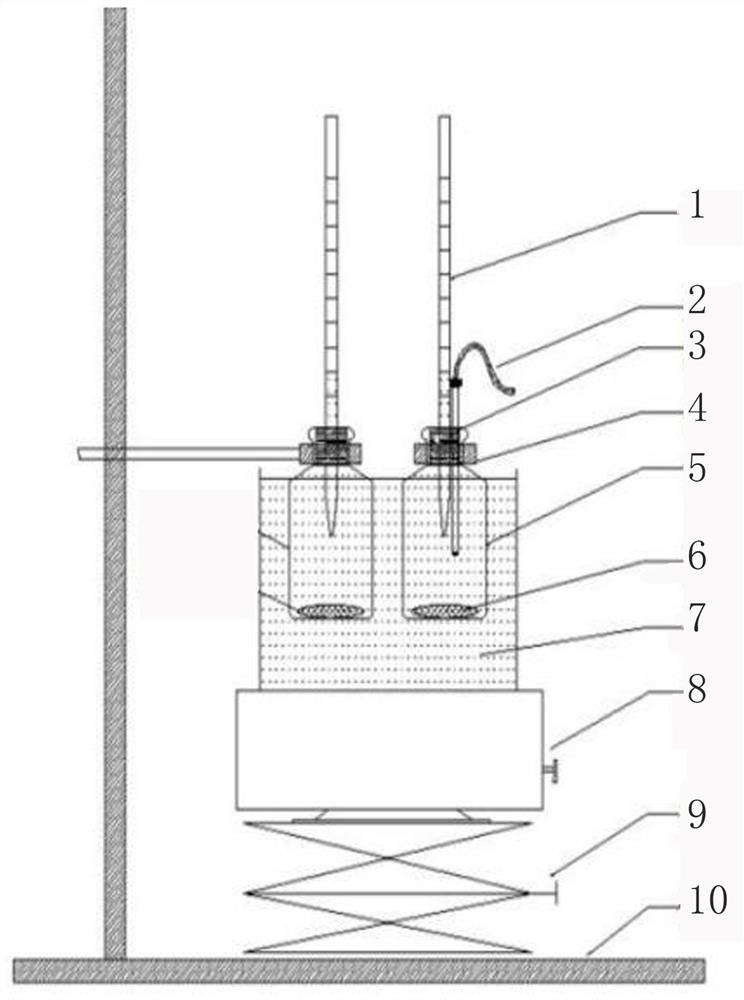

[0034] A method for measuring volume change of chemical shrinkage and fiber-resin contact angle during resin curing process, the main test steps are as follows:

[0035] (1) First, mix a sufficient amount of the resin curing system to be tested (i.e. sample 6) uniformly in proportion, vacuumize and defoam for 15 minutes, use it to fill the sample bottle 5 with precise scale, set equal weight without adding curing agent The resin filled with another identical sample bottle 5 is used as a control group, and the capacity of two groups of sample bottles is 125ml;

[0036] (2) Clean and dry the pipette. In this example, the selected pipette 1 has a range of 1ml and an accuracy of 0.01ml. The pipette 1 and the temperature sensor 2 are installed together on the rubber stopper 3, and the rubber stopper 3 is plugged on the sample bottle filled with resin to check its tightness, and the bottle body is fixed with the test tube clamp 4, while ensuring that the pipette 1 remains Vertical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com