Automatic refueling control system suitable for liquid

An automatic refueling and control system technology, applied in control/adjustment system, liquid level control, non-electric variable control, etc., can solve the problems of high production cost, low production efficiency, difficulties, etc., achieve the overall layout specification and improve production efficiency , the effect of improving the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

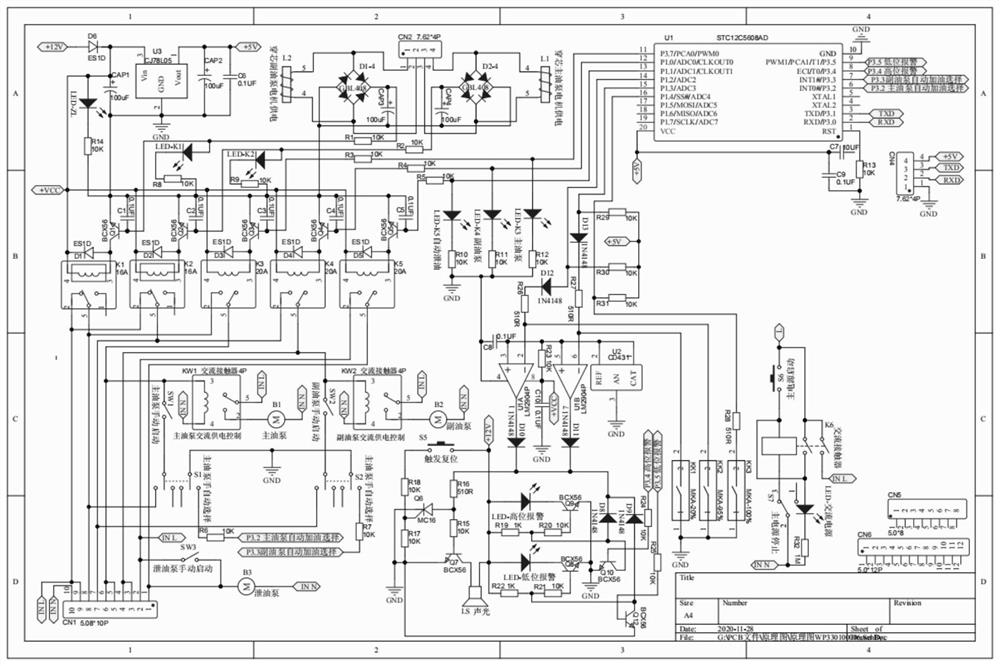

Image

Examples

Embodiment 1

[0024] The automatic refueling control system suitable for liquids is controlled by the MCU in two ways, including the automatic control of the main oil pump and the manual control of the main oil pump, and the automatic control of the standby oil pump and the manual control of the standby oil pump. The two control modes are interlocked work in the state;

[0025] The MCU controls the low-level detection input terminal IO of the main oil pump, which is used for when the low-level oil shortage is under the low-level signal, the system performs buzzer alarm work, outputs the main oil pump refueling signal, and starts automatic refueling. When the level signal starts to trigger the refueling signal, the system will continue to refuel until the high level of the built-in liquid level sensor closes, and stop triggering under the low level signal to indicate that the oil is full;

[0026] When the MCU controls the operation of the main oil pump, the MCU is used to control the standb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com