Combined water supply method of secondary water supply high-level water tank and low-level water tank

A high-level water tank and low-level water tank technology, which is applied in the configuration of water supply devices, water supply devices, and water supply pools, etc., can solve problems such as inappropriateness, indiscrimination, and waste of tap water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

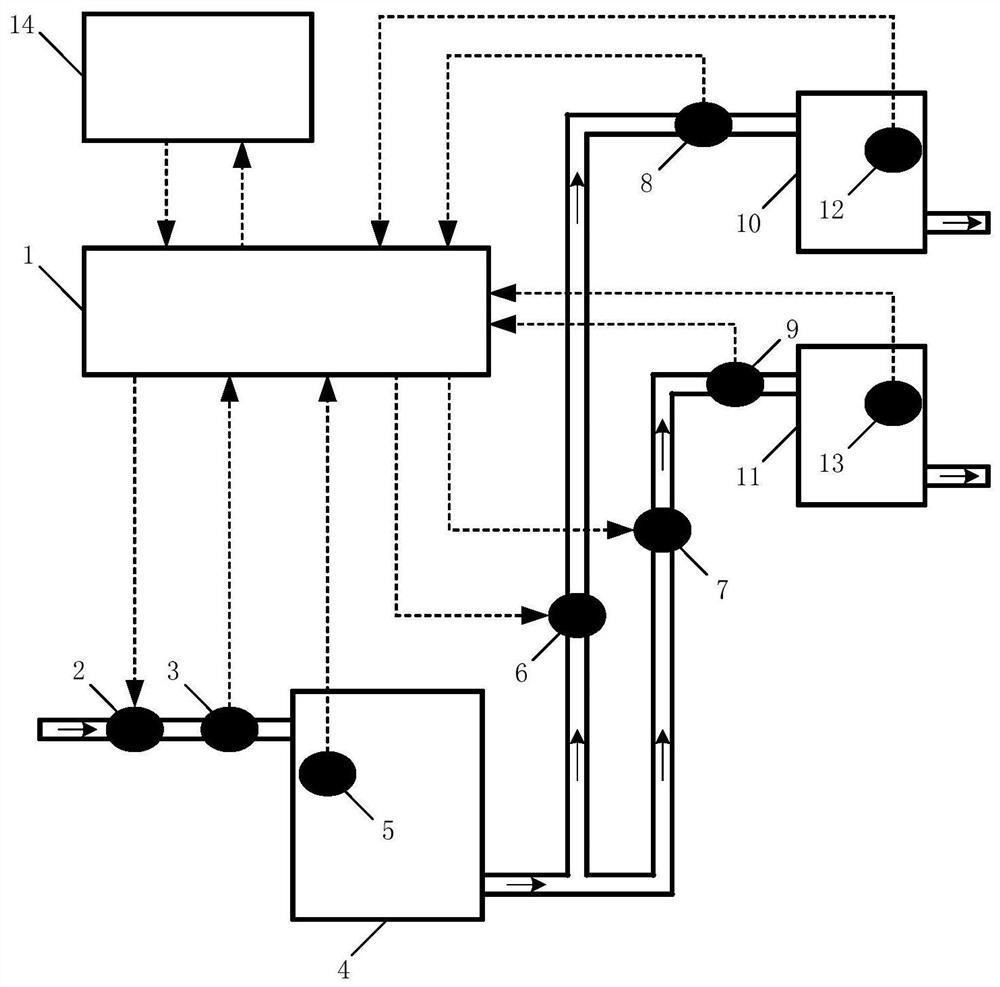

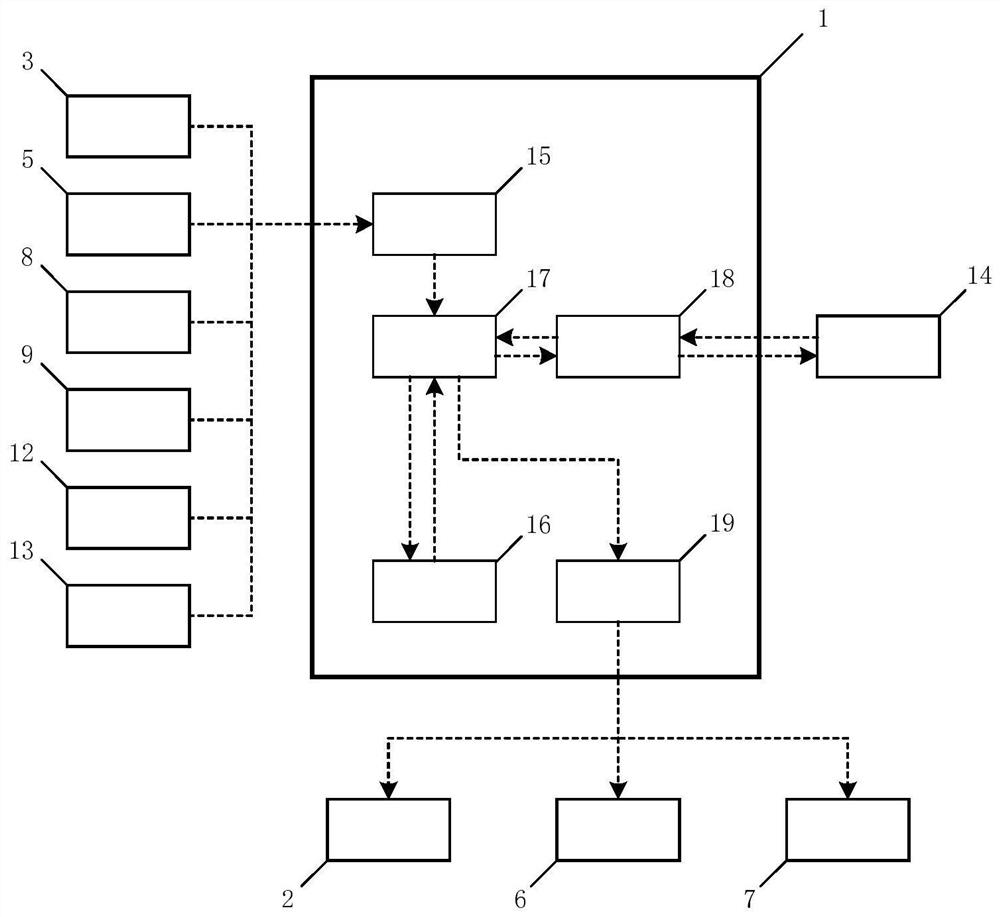

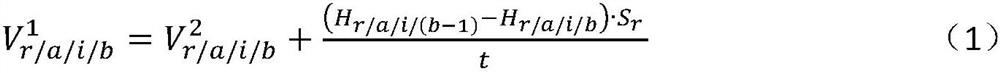

[0151] This embodiment provides a combined water supply method for the secondary water supply high-level water tank and low-level water tank, such as figure 1 , 2 As shown, the device or equipment includes a control system, a low-level water tank 4 and at least one high-level water tank, an automatic valve 2 and a flowmeter are provided at the water inlet of the low-level water tank 4, and an automatic valve 2 and a flowmeter are arranged at the water inlet of each high-level water tank. There are water inlet pumps and flowmeters, and liquid level gauges are arranged in the low-level water tank 4 and in each high-level water tank; the control system includes an intelligent controller 1 and a remote controller 14, and the intelligent controller 1 includes a data acquisition module 15 , data storage module 16, data processing module 17, communication module 18 and control module 19, data acquisition module 15 is connected with data processing module 17, all liquid level gauges a...

Embodiment 2

[0279] In order to further confirm the accuracy, effectiveness and practicability of the method described in Example 1, the applicant now further describes the scheme of Example 1 in conjunction with specific actual data, as follows:

[0280] Set the volume of a high-level water tank A as 35×20×20=14000dm 3 , the longitudinal sectional area of the water tank is 700dm 2 , the minimum liquid level allowed for water storage in the water tank is 2.0dm, and the maximum liquid level allowed for water storage in the water tank is 17.4dm; the volume of the high-level water tank B is 40×20×20=16000dm 3 , the longitudinal sectional area of the water tank is 800dm 2 , the minimum liquid level allowed for water storage in the water tank is 2.0dm, and the maximum liquid level allowed for water storage in the water tank is 18dm; the volume of the low-level water tank is 55×30×20=33000dm 3 , the longitudinal sectional area of the water tank is 1650dm 2 , the minimum liquid level all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com