Wafer detection method

A detection method and wafer technology, applied in the direction of semiconductor/solid-state device testing/measurement, can solve problems such as disadvantages, improve process yield, etc., and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

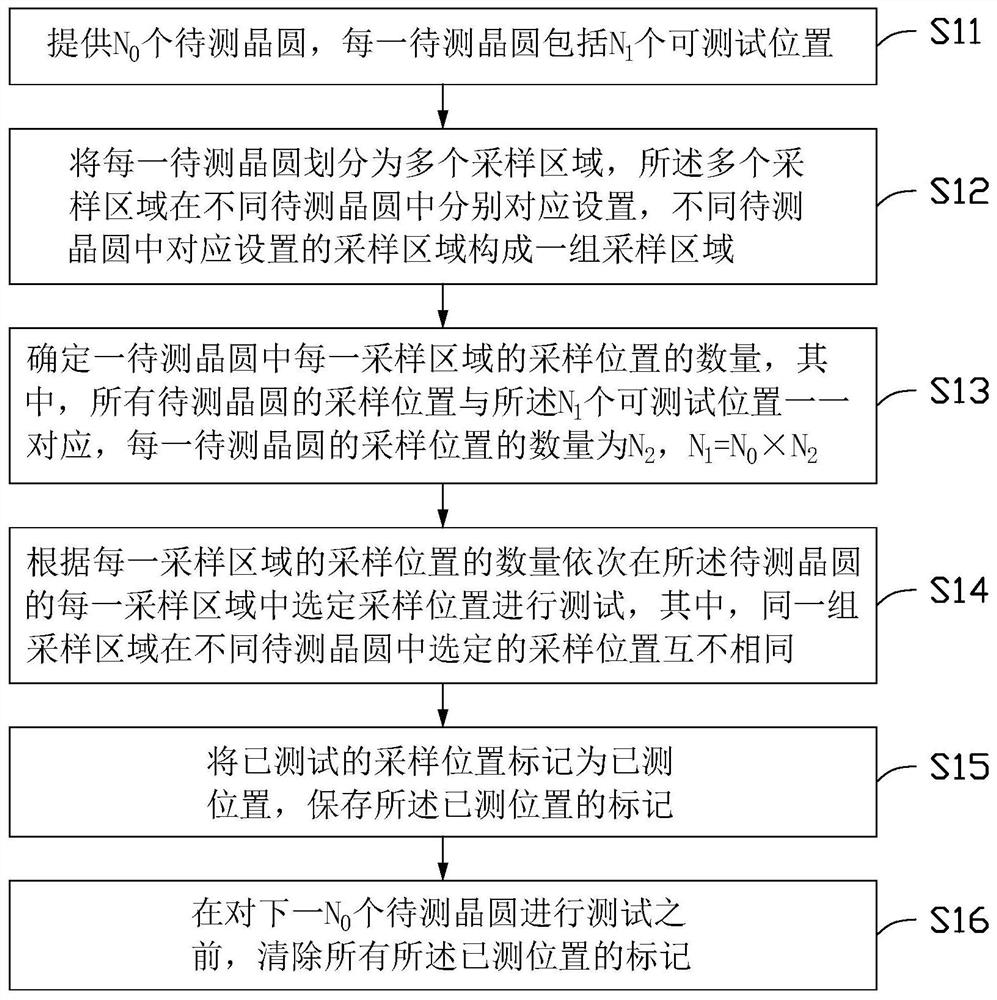

[0034] see figure 1 , the first embodiment of the present invention provides a wafer detection method, including the following steps:

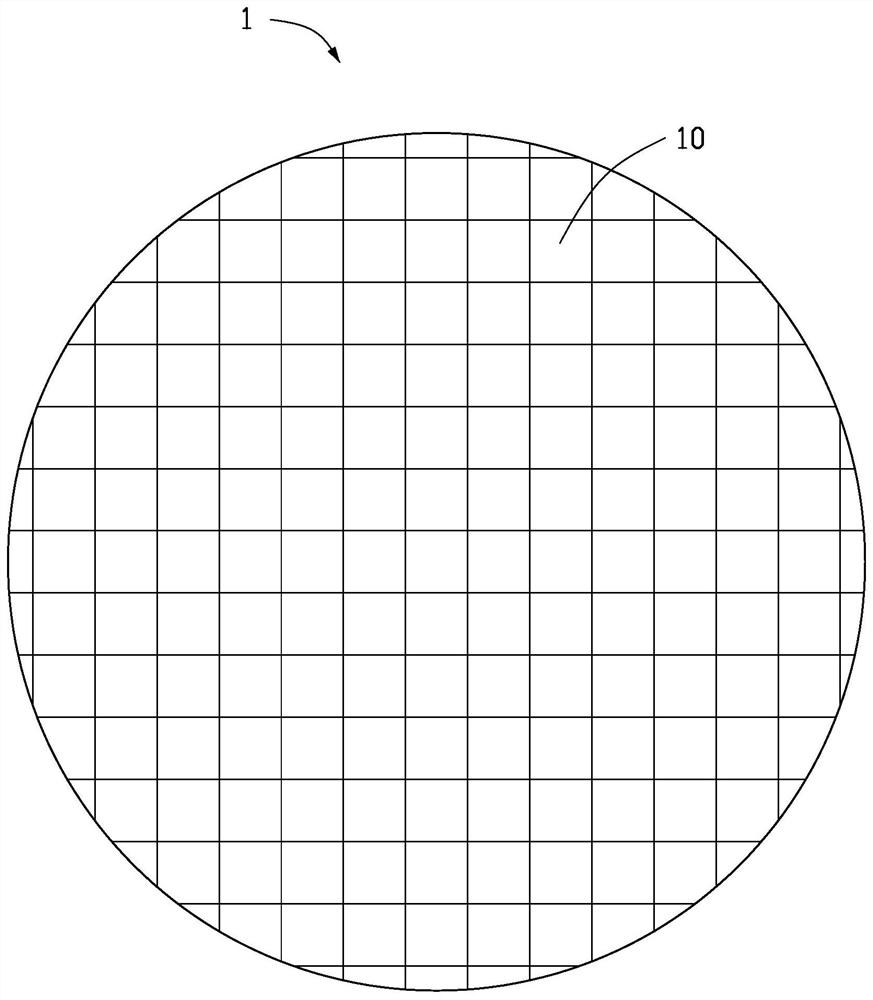

[0035] Step S11, please also refer to figure 2 , providing N 0 Wafers 1 to be tested, each wafer 1 to be tested includes N 1 10 testable locations.

[0036] For example, the number of wafers 1 to be tested is 20 (ie N 0 =20). Each wafer 1 to be tested includes 160 testable positions 10 (ie N 1 =160).

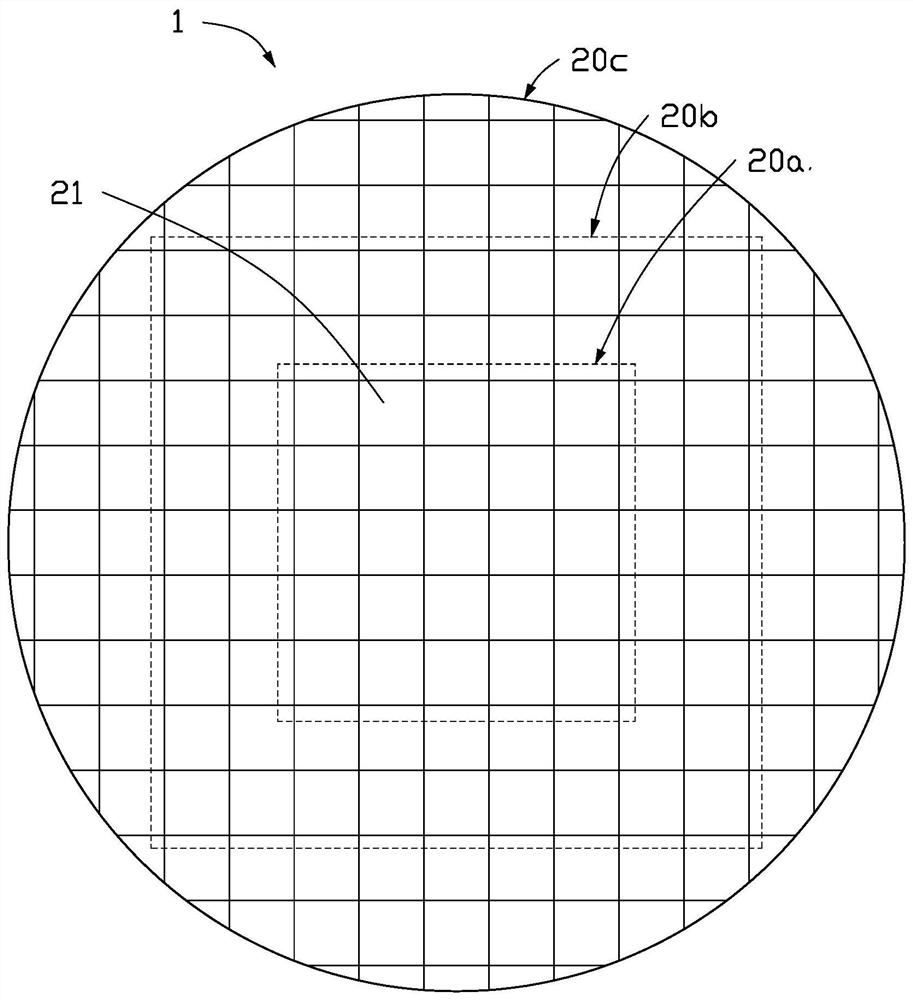

[0037] Step S12, please also refer to image 3 , divide each wafer 1 to be tested into a plurality of sampling areas according to a predetermined division method, the plurality of sampling areas are correspondingly set in different wafers 1 to be tested, and the sampling areas correspondingly set in different wafers 1 to be tested are Regions form a set of sampling regions.

[0038] As shown in the figure, each wafer 1 to be tested may include three sampling areas, respectively marked as a first sampling area 20a, a second sampling are...

no. 2 approach

[0059] see Figure 7 , the second embodiment of the present invention also provides a wafer detection method, including the following steps:

[0060] Step S71, please also refer to figure 2 , providing N 0 Wafers 1 to be tested, each wafer 1 to be tested includes N 1 10 testable locations.

[0061] For example, the number of wafers 1 to be tested is 40 (ie N 0 = 40). Each wafer 1 to be tested includes 160 testable positions 10 (ie N 1 =160).

[0062] Step S72, please refer to image 3 , divide each wafer 1 to be tested into a plurality of sampling areas according to a predetermined division method, the plurality of sampling areas are correspondingly set in different wafers 1 to be tested, and the sampling areas correspondingly set in different wafers 1 to be tested are Regions form a set of sampling regions.

[0063] As shown in the figure, each wafer 1 to be tested may include three sampling areas, respectively marked as a first sampling area 20a, a second sampling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com