Wireless module testing method and device

A technology of wireless module and testing method, applied in the field of wireless communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] As described below, the embodiment of the present invention provides a wireless module testing method, which can perform batch testing of each wireless module to be tested in the device under test, and the test items may include wireless signal receiving functions and indicators, wireless signal sending functions and indicators, etc. .

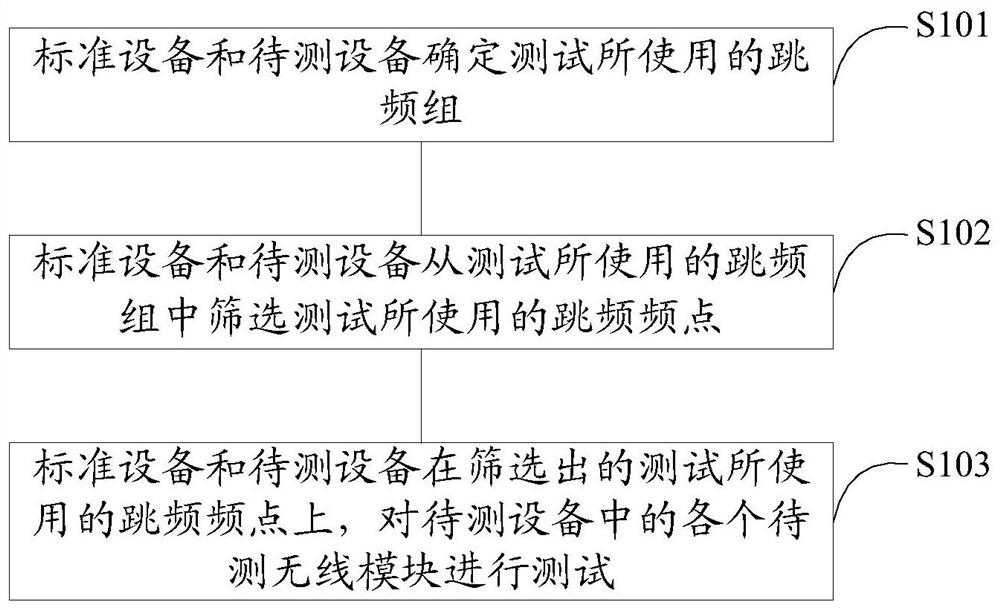

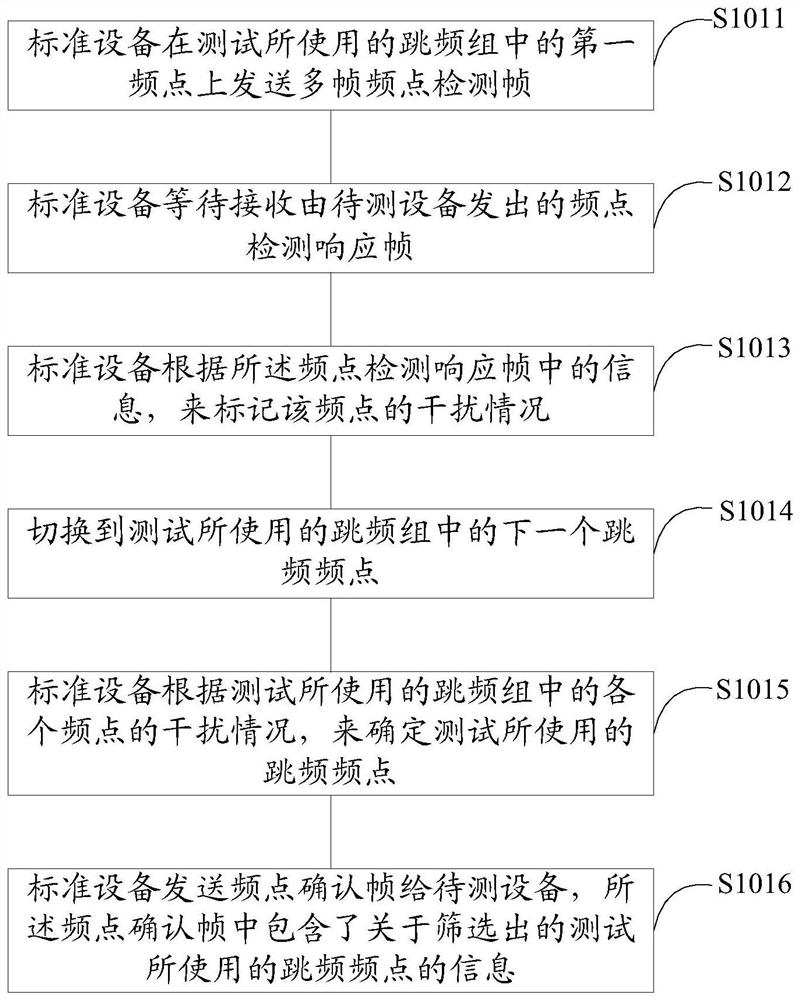

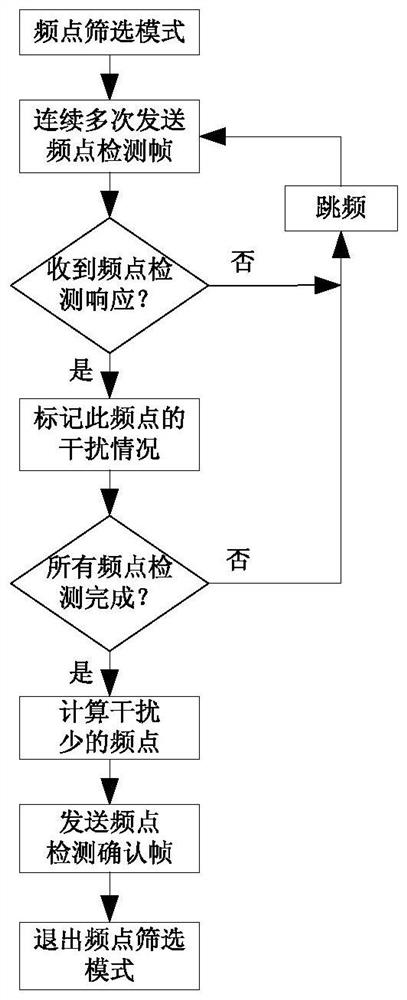

[0110] refer to figure 1 The flow chart of the wireless module test method is shown in the following detailed steps:

[0111] S101. The standard equipment and the equipment under test determine a frequency hopping group used for testing.

[0112] Among them, there are multiple groups of frequency hopping groups, and different workbenches use different frequency hopping groups (and each device uses a unique ID number). Each workbench includes standard equipment and equipment to be tested, and the equipment to be tested includes multiple The wireless module, the standard equipment and the equipment under test on the same workbench use t...

Embodiment 2

[0221] As described below, an embodiment of the present invention provides a wireless module testing device.

[0222] The wireless module testing device includes:

[0223] a processor adapted to load and execute instructions of a software program;

[0224] A memory adapted to store a software program comprising instructions for performing the following steps:

[0225] The standard equipment and the equipment under test determine the frequency hopping group used in the test. There are multiple frequency hopping groups, and different workbenches use different frequency hopping groups. Each workbench includes standard equipment and equipment under test, and the equipment under test Including multiple wireless modules to be tested, the standard equipment and the equipment to be tested on the same workbench use the same frequency hopping group during the test;

[0226] The standard equipment and the equipment under test screen the frequency hopping frequency points used in the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com