Water conservancy aquatic plant removing equipment

A technology of aquatic plants and equipment, applied in the direction of cutters, agricultural machinery and implements, applications, etc., can solve problems such as unfavorable aquatic plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

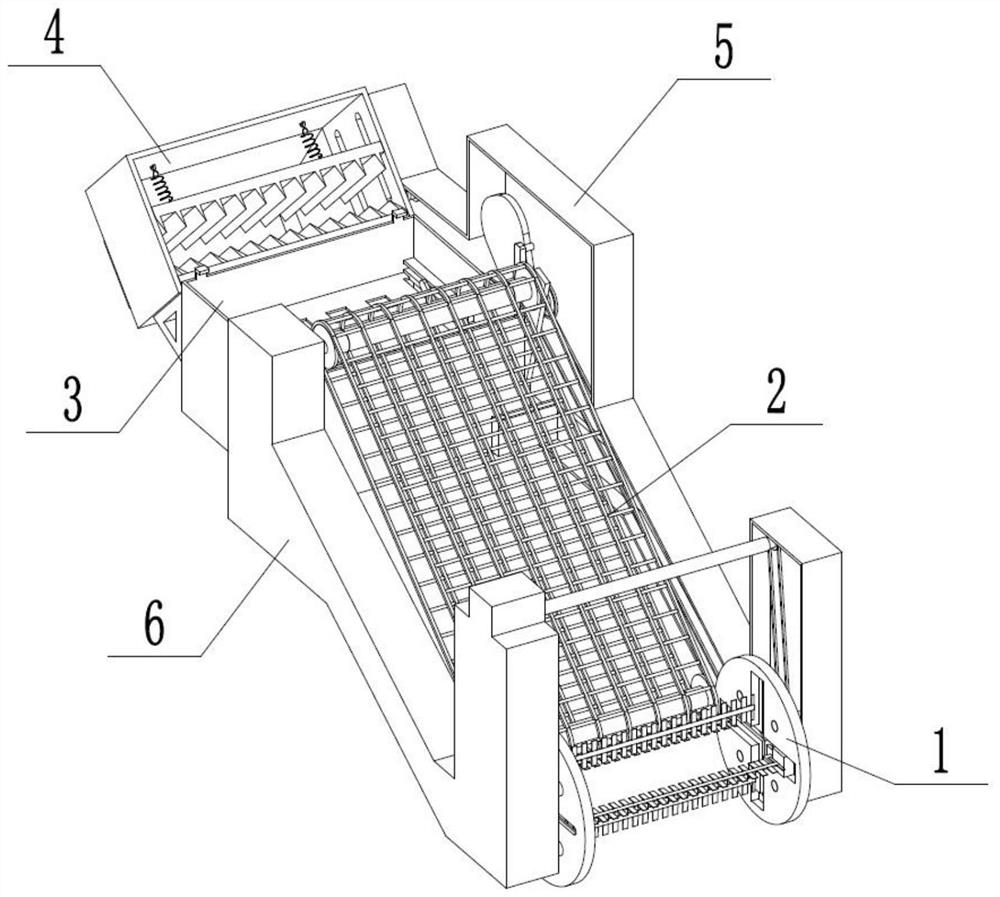

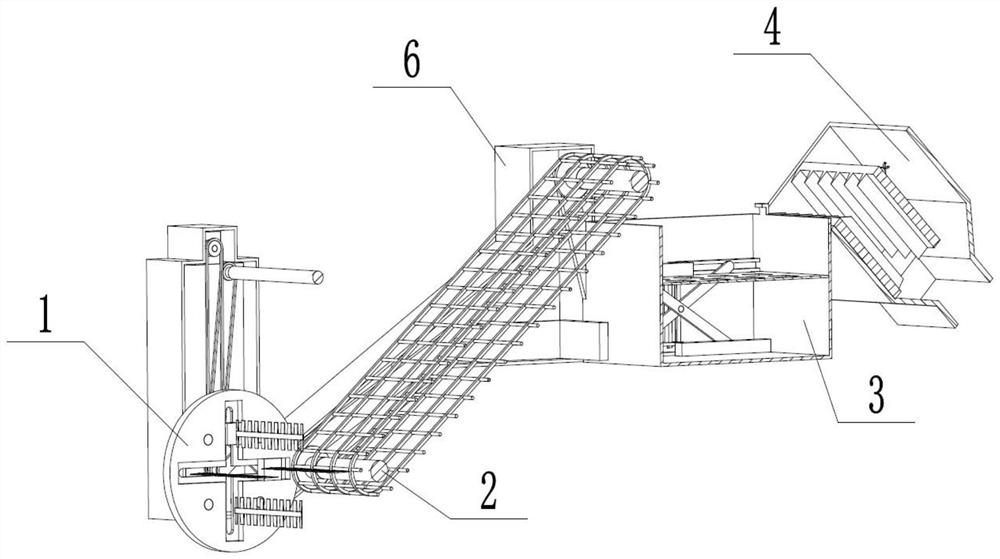

[0039] Combine below Figure 1-20 Describe this embodiment, a kind of water conservancy and water weed removal equipment, comprise mowing device 1, feeding device 2, cleaning device 3, pulverizing device 4, casing weldment A5, casing weldment B6, described mowing device 1 and feeding Device 2 is connected, feeding device 2 is connected with cleaning device 3, cleaning device 3 is connected with crushing device 4, mowing device 1 is connected with cleaning device 3, mowing device 1, feeding device 2, cleaning device 3, crushing The devices 4 are all connected with the casing weldment A5, and the mowing device 1, the feeding device 2, and the cleaning device 3 are all connected with the casing weldment B6.

specific Embodiment approach 2

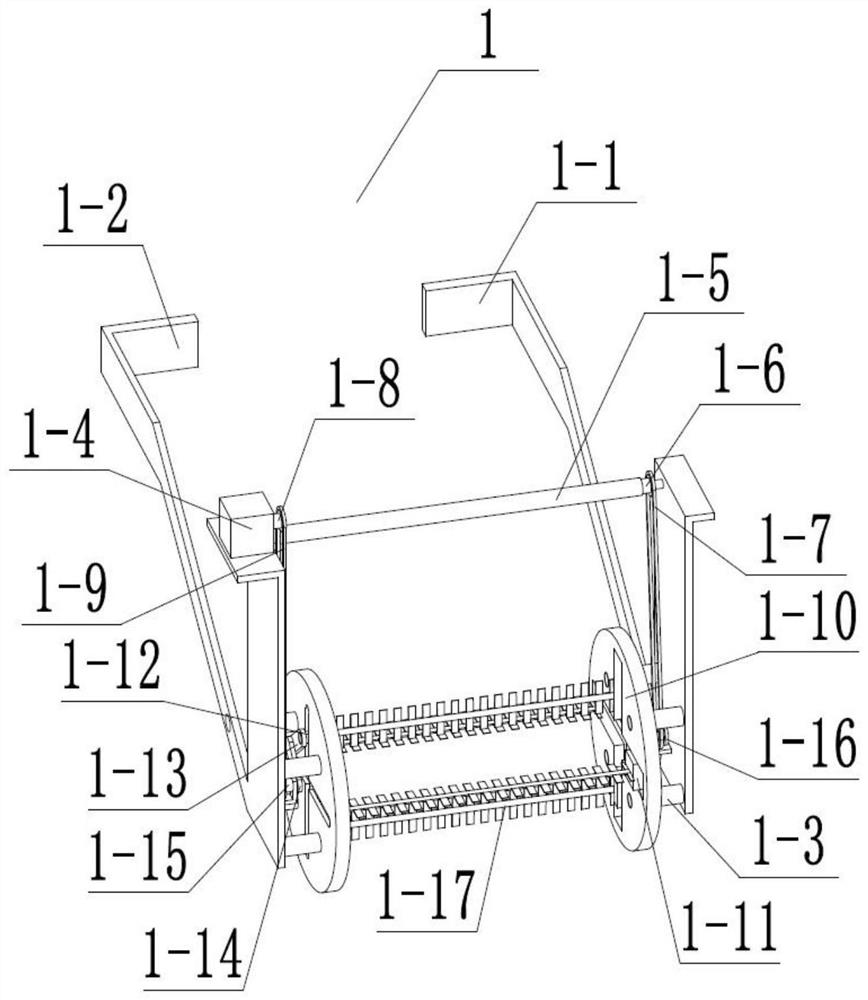

[0041] Combine below Figure 1-20 Describe this embodiment, this embodiment will further describe the first embodiment, the mowing device 1 includes a mowing fixed plate A1-1, a mowing fixed plate B1-2, a mowing fixed shaft 1-3, and a motor 1-4 , motor shaft 1-5, gear A1-6, chain A1-7, gear B1-8, chain B1-9, slider fixed plate 1-10, slider 1-11, slider connecting shaft 1-12, slider Block connecting plate 1-13, rotating plate 1-14, double gear A1-15, double gear B1-16, cutting blade 1-17, mowing fixed shaft 1-3 is welded and connected with mowing fixed plate A1-1, mowing The grass fixed shaft 1-3 is welded and connected with the mowing fixed plate B1-2, the mowing fixed shaft 1-3 is fixedly connected with the slider fixed plate 1-10, and the motor 1-4 is fixedly connected with the mowing fixed plate B1-2, The output shaft of the motor 1-4 is connected in rotation with the gear B1-8, the gear B1-8 is connected in rotation with the chain B1-9, the chain B1-9 is connected in rota...

specific Embodiment approach 3

[0044] Combine below Figure 1-20 Describe this embodiment, this embodiment will further describe the first embodiment, the feeding device 2 includes a transmission chain 2-1, a transmission gear 2-2, a rotating shaft A2-3, a rotating shaft B2-4, a chain welding shaft 2-5, Double gear C2-6, chain C2-7, transmission chain 2-1 is connected in rotation with transmission gear 2-2, transmission gear 2-2 is connected with rotation shaft A2-3, rotation shaft B2-4 respectively, transmission chain 2-1 is connected with rotation The chain welding shaft 2-5 is welded and connected, the double gear C2-6 is rotatably connected with the rotating shaft B2-4, the chain C2-7 is rotatably connected with the double gear C2-6, and the chain C2-7 is rotatably connected with the double gear B1-16.

[0045] The double gear B1-16 rotates to drive the chain C2-7, which drives the double gear C2-6 to rotate, so that the rotating shaft B2-4 drives the transmission gear 2-2 to rotate, and the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com