A shower gel raw material extraction system

An extraction system and shower gel technology, applied in solid solvent extraction, grain processing, transportation and packaging, etc., can solve the problem of inability to quickly extract shower gel raw materials, and achieve the effect of improving effective work rate, preventing accumulation and rapid extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

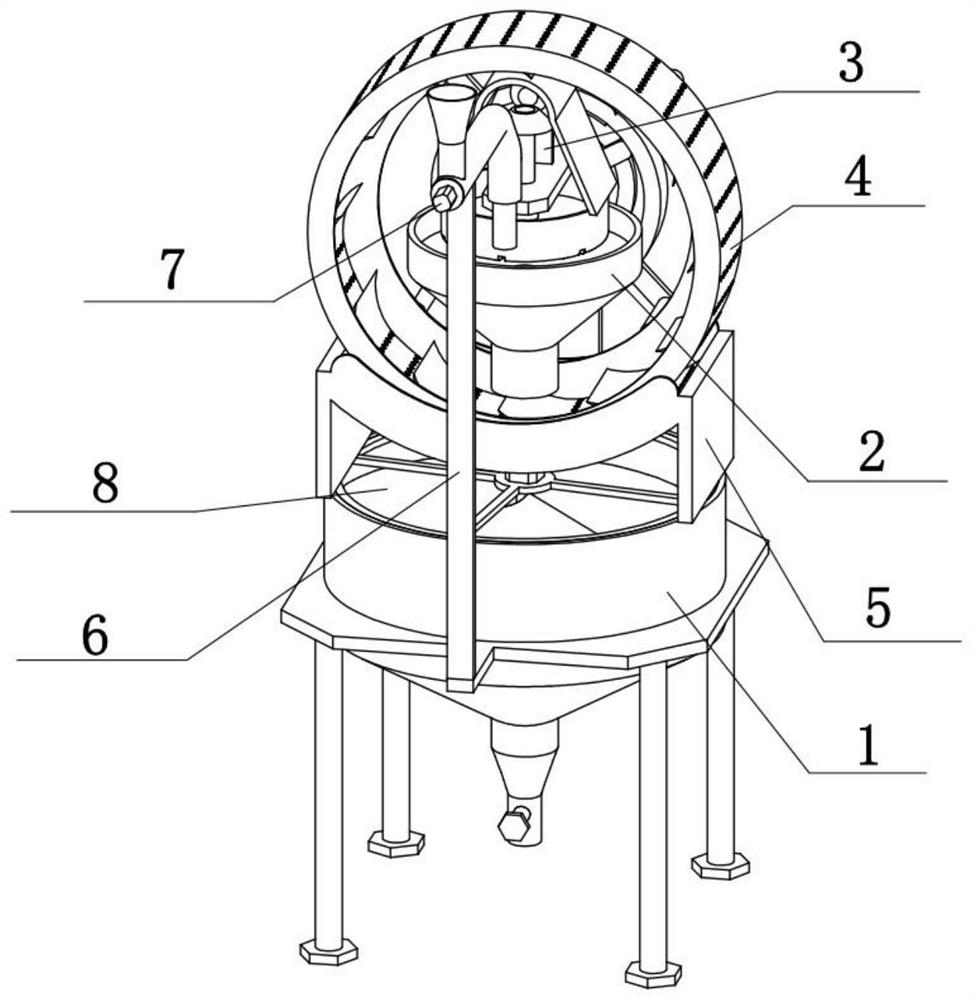

[0031] Combine below Figure 1-10 Describe this embodiment, a raw material extraction system for shower gel, including a bracket assembly 1, a primary grinding assembly 2, a driving assembly 3, a circulating filter assembly 4, a fine grinding assembly 5, a feeding assembly 6, a feeding assembly 7 and a mixing assembly 8 , the primary grinding assembly 2 is connected to the bracket assembly 1, the driving assembly 3 is fixedly connected to the bracket assembly 1, the driving assembly 3 and the primary grinding assembly 2 are engaged for transmission, and the circulating filter assembly 4 is rotatably connected to the bracket assembly 1, and the driving assembly 3 and the circulating filter assembly 4 are meshed and driven, the fine grinding assembly 5 is fixedly connected to the bracket assembly 1, the feeding assembly 6 is fixedly connected to the front end of the bracket assembly 1, the feeding assembly 7 is fixedly connected to the feeding assembly 6, and the mixing assembly ...

specific Embodiment approach 2

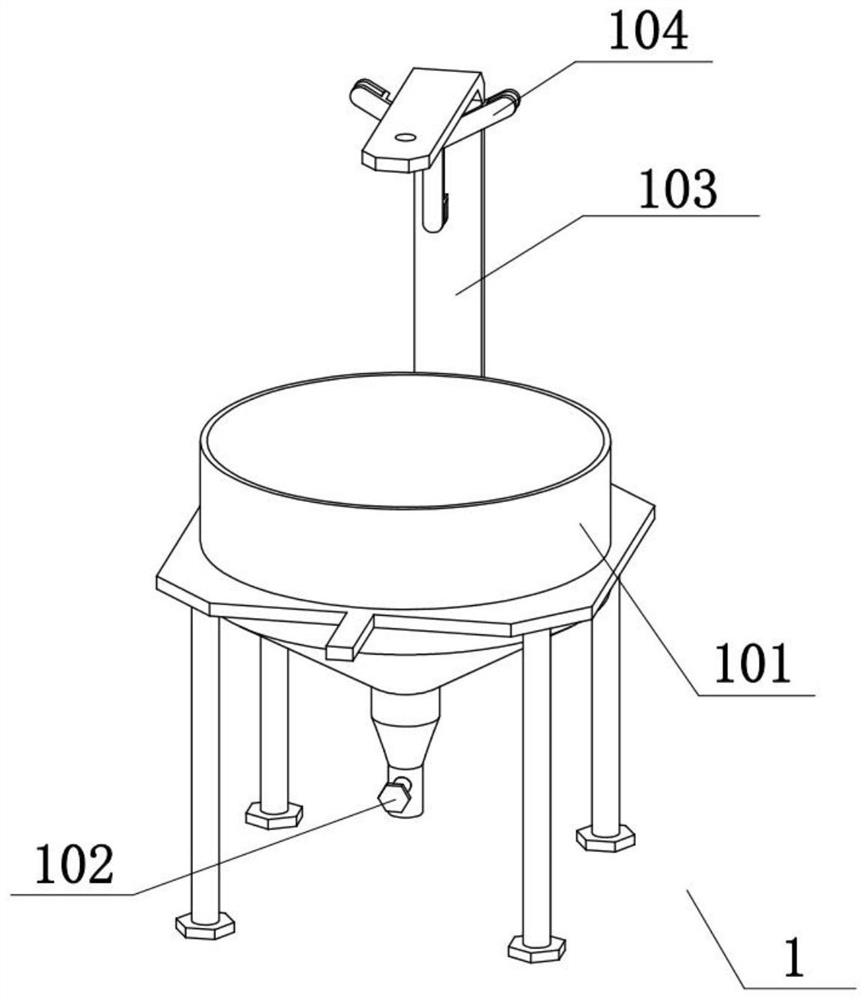

[0033] Combine below Figure 1-10Illustrate this embodiment, described bracket assembly 1 comprises mixing barrel 101, blanking valve 102, L vertical plate 103 and turret 104, and the lower end of mixing barrel 101 is provided with blanking valve 102, and L vertical plate 103 is fixedly connected in mixing barrel On the rear side of 101, the turret 104 is fixedly connected to the L vertical plate 103.

specific Embodiment approach 3

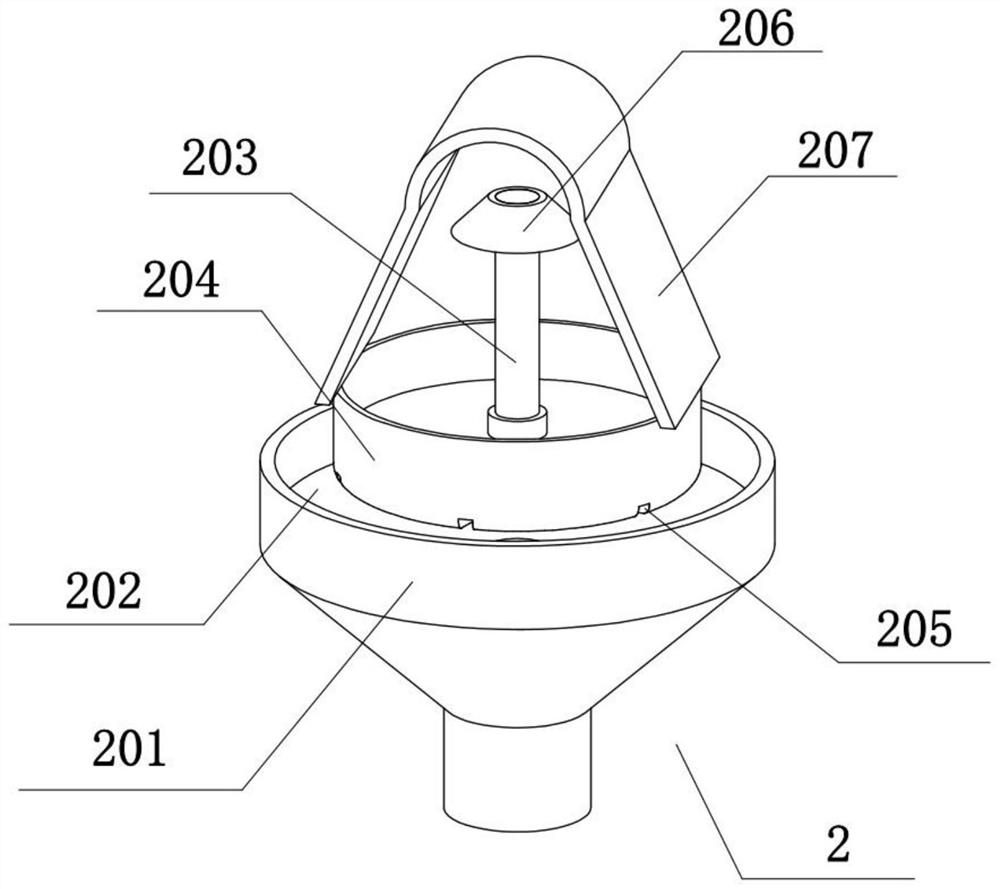

[0034] Combine below Figure 1-10 To illustrate this embodiment, the primary grinding assembly 2 includes a grinding cone bucket 201, a lower grinding disc 202, an upper grinding shaft 203, an upper grinding disc 204, a scraper trough 205, a driven bevel tooth 206 and a baffle plate 207, and the grinding cone The shaped bucket 201 is fixedly connected to the front end of the turret 104, the lower grinding disc 202 is fixedly connected to the grinding conical bucket 201, the upper grinding shaft 203 is rotatably connected to the L vertical plate 103, and the upper grinding disc 204 is fixedly connected to the upper grinding shaft 203 On the top, scraper grooves 205 are evenly distributed on the upper grinding disc 204 , the driven bevel teeth 206 are fixedly connected to the upper grinding shaft 203 , and the shielding plate 207 is fixedly connected to the upper grinding disc 204 .

[0035] The driving bevel gear 305 meshes to drive the driven bevel gear 206 to rotate, the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com