A kind of titanium dioxide photocatalytic thin film of three-layer structure and preparation method thereof

A technology of photocatalytic thin film and three-layer structure, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of difficult application and instability, and achieve high efficiency Effects of light absorption, improved mobility, and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

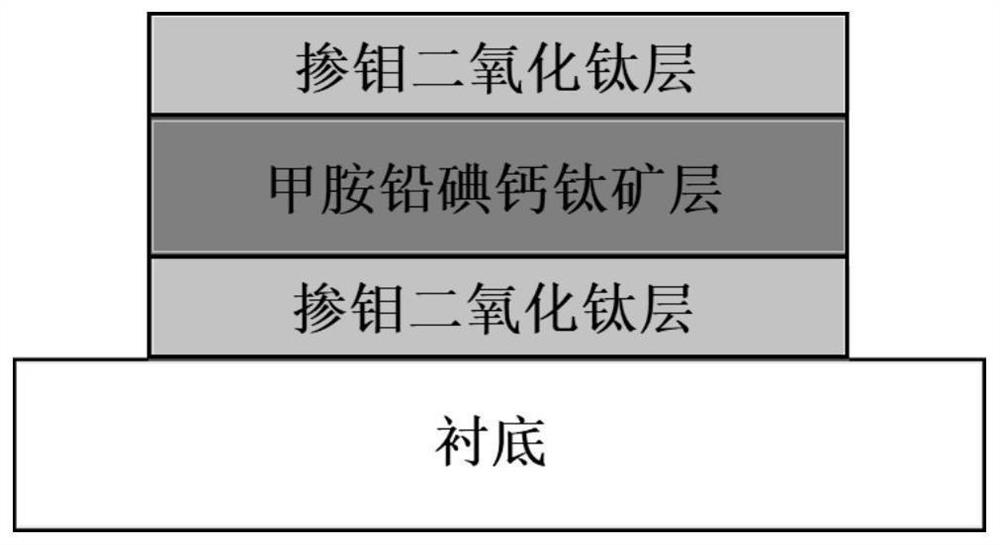

[0030] The bottom and top layers are pure titanium dioxide sputtering: using TiO 2 Ceramic target, the substrate temperature is 80°C, the total pressure of oxygen-argon mixed gas is 0.3Pa, where O 2 The ratio of partial pressure to the total air pressure is 1.0%, the sputtering time is 60min, the sputtering power is 120W, and the sputtering power density is 42.5kW / m 2 .

[0031] Middle perovskite layer CH 3 NH 3 PB 3 Preparation: PbI first 2 Deposited on the underlying TiO by thermal evaporation 2 Above, put the sample into a sealable glass container in the vacuum chamber, and put CH at the opposite position of the sample. 3 NH 3 I, close the glass container (the glass container is in a vacuum state at this time). Insulate at 120°C for 60 minutes. The preparation conditions are as follows: the evaporation boat is a molybdenum boat, and the PbI 2 The amount is 0.3g, the evaporation current is 100A, the time is 2min, CH 3 NH 3 The amount of I was 0.5 g.

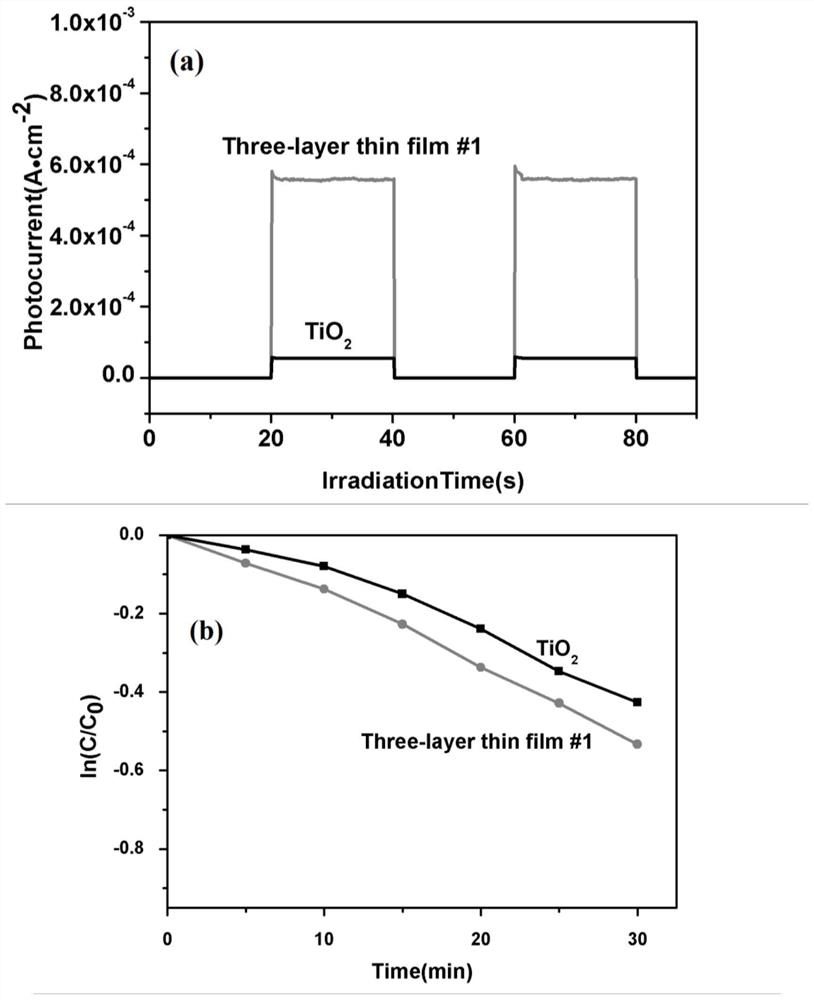

[0032] The...

Embodiment 2

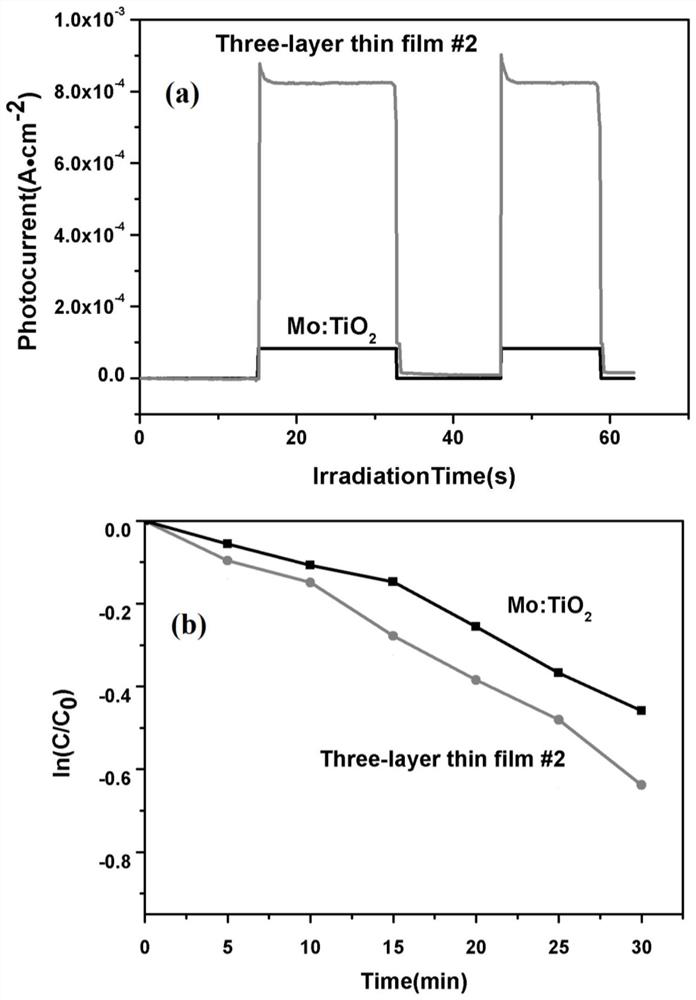

[0034] Change both bottom and top layers of pure titania to Mo:TiO 2 layer, wherein the Mo / Ti atomic ratio in the Mo-doped titania ceramic target is about 0.5%, and other equipment conditions are the same as in Example 1.

[0035] The test results of photocurrent density and photocatalytic degradation performance of samples under ultraviolet-visible light are as follows: image 3 (a), image 3 (b) shown. Three-layer Mo:TiO 2 -CH 3 NH 3 PB 3 -Mo:TiO 2 The photocurrent of the film sample is about 8.2×10 -4 A / cm 2 , is the same thickness as Mo:TiO 2 Thin film (photocurrent about 8×10 -5 A / cm 2 ) 10.3 times that of pure TiO with the same thickness 2 Film light 13.7 times. The photocatalytic degradation rate constant of the three-layer sample is -0.022, and the same thickness of Mo:TiO 2 The film is about -0.013, and the photocatalytic degradation rate is Mo:TiO 2 1.7 times that of thin film, is pure TiO 2 2 times that of film.

Embodiment 3

[0037] The bottom and top layers of Mo:TiO 2 The sputtering power in the preparation conditions of the layer is changed to 200W, and the sputtering power density is 70.8kW / m 2 . Other conditions are with embodiment 2.

[0038] The test results of photocurrent density and photocatalytic degradation performance of samples under ultraviolet-visible light are as follows: Figure 4 (a), Figure 4 (b) shown. Three-layer Mo:TiO 2 -CH 3 NH 3 PB 3 -Mo:TiO 2 The photocurrent of the film sample is about 8.6×10 -4 A / cm 2 , is the same thickness as Mo:TiO 2 Thin film (photocurrent about 8×10 -5 A / cm 2 ) 10.8 times that of pure TiO with the same thickness 2 Film light 14.3 times. The photocatalytic degradation rate constant of the three-layer sample is -0.026, and the same thickness of Mo:TiO 2 The film is about -0.013, and the photocatalytic degradation rate is Mo:TiO 2 Twice as thin film, is pure TiO 2 2.4 times that of film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com