Workpiece shaft groove foreign matter suction mechanism

A technology of suction mechanism and workpiece axis, applied in the field of assembly parts, can solve the problems of influence, foreign matter and oil residue, poor product quality, etc., to avoid damage, reduce workpiece wear, and ensure full contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

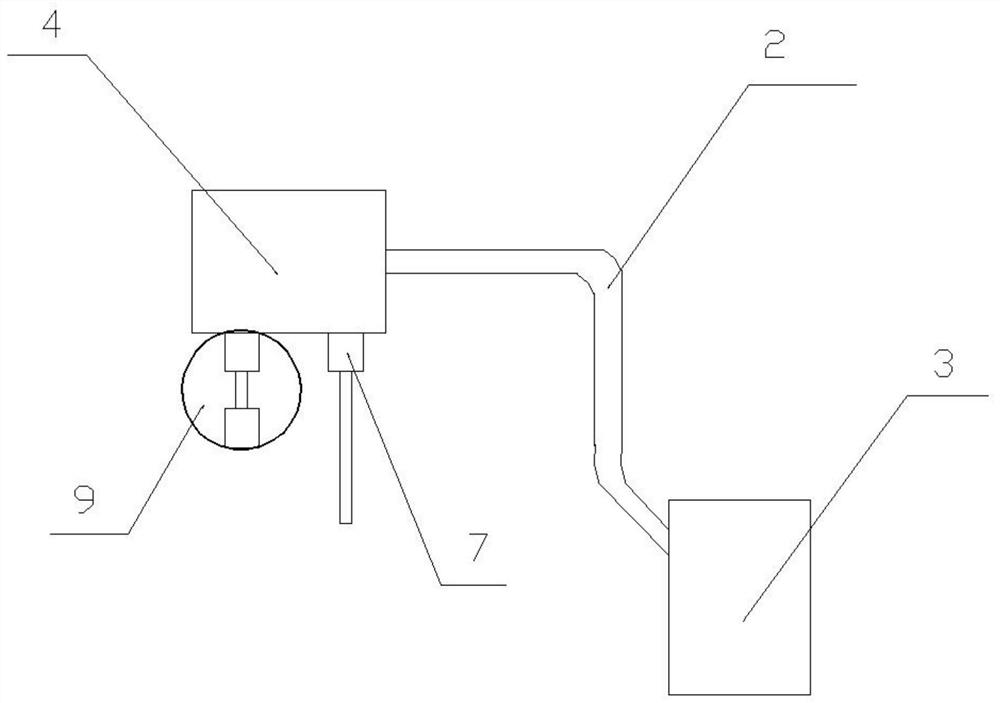

[0046] The present invention provides a mechanism for absorbing foreign matter in a workpiece shaft groove, which is characterized in that it includes a suction device, a suction pipe 2, a control device 3, a detection device 24, a positioning device 7, and a protective shell 4;

[0047] The suction device and the control device 3 are connected through the suction pipe 2, the right side of the suction device is provided with a positioning device 7, the upper part of the suction device is provided with a fixed plate 33, the upper part of the positioning device 7 is connected with the fixed plate 33, and the upper part of the fixed plate 33 is connected by a nut There is a detection device 24, and a protective case 4 is arranged above the fixed plate 33;

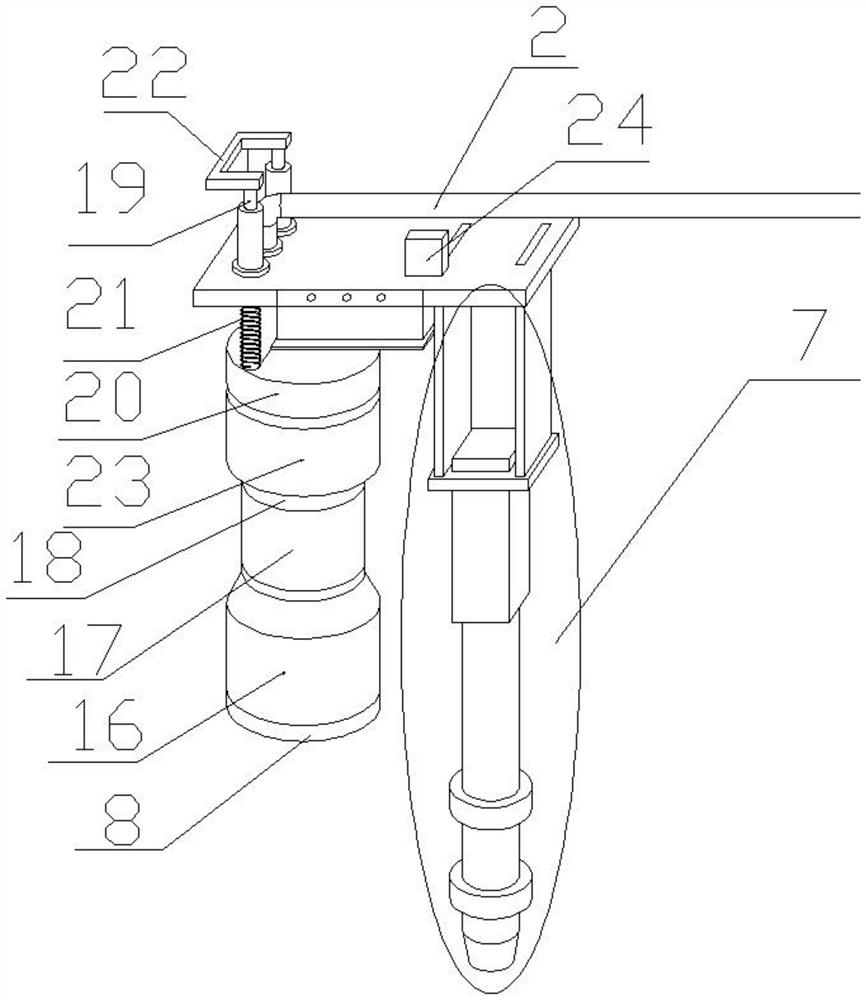

[0048] The suction device is made up of a foreign body suction part 8 and a buffer device, and the buffer device is arranged above the foreign matter suction part 8;

[0049] The buffer device is composed of an optical axis an...

Embodiment 2

[0069] According to the strength and strength of absorbing foreign matter, select the control device 3 that meets the power, and then select the appropriate control element, solenoid valve, pipe diameter, etc. according to the power of the control device 3 .

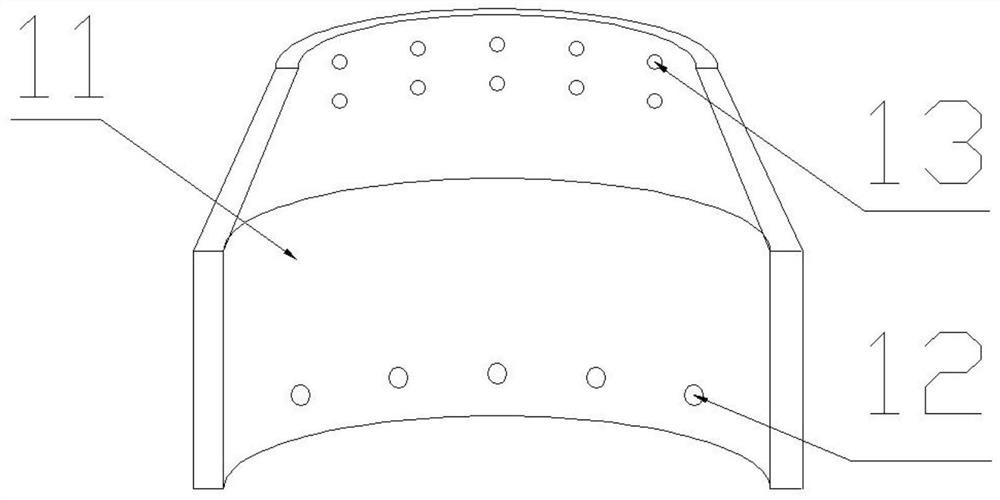

[0070] According to the size of the workpiece, the inner cavity 11 of the foreign matter suction part 8 is designed so that the bottom is blown while the upper part is inhaled to ensure that the foreign matter is blown off and sucked away by the upper suction hole 13, and is transported to the control device 3 through the suction pipe 2 Internal foreign matter bucket.

[0071] According to the size of the foreign matter absorber 8, a self-aligning unit 9 is designed above the foreign matter absorber 8 to ensure that when the workpiece and the foreign matter absorber 8 are in contact, the workpiece and the foreign matter absorber 8 are tightly combined without air leakage.

[0072] Attach a detection device 4 to the sucti...

Embodiment 3

[0074] When using the present invention, when the workpiece reaches the foreign matter absorbing part 8, the tooling drives the workpiece to rise, and at this time the positioning column of the positioning device 7 contacts the workpiece transmission platform, because the tooling drives the workpiece to rise, and the positioning column is arranged inside the telescopic support, Therefore, the positioning column moves straight up inside the telescopic support until the top of the positioning column contacts the fixed plate 33. At this time, the workpiece rises to the position of the foreign matter absorbing part 8, and the foreign matter absorbing part 8 completely encloses the workpiece. At this time, the worker controls the external air pump Work, the air pump is connected with the air pump connection hole 28 through the blowing pipe of the air pump, the gas of the air pump passes through the blowing hole 12 through the blowing pipe, and blows air to the workpiece. The foreign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com