Device and method for detecting contents of particulate matters and heavy metal elements in tail gas

A technology for element content and detection device, applied in measurement devices, sampling devices, particle suspension analysis, etc., can solve the problems of complex operation, cumbersome operation, expensive instruments and equipment, etc., to ensure absorption efficiency, avoid condensation, and improve detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

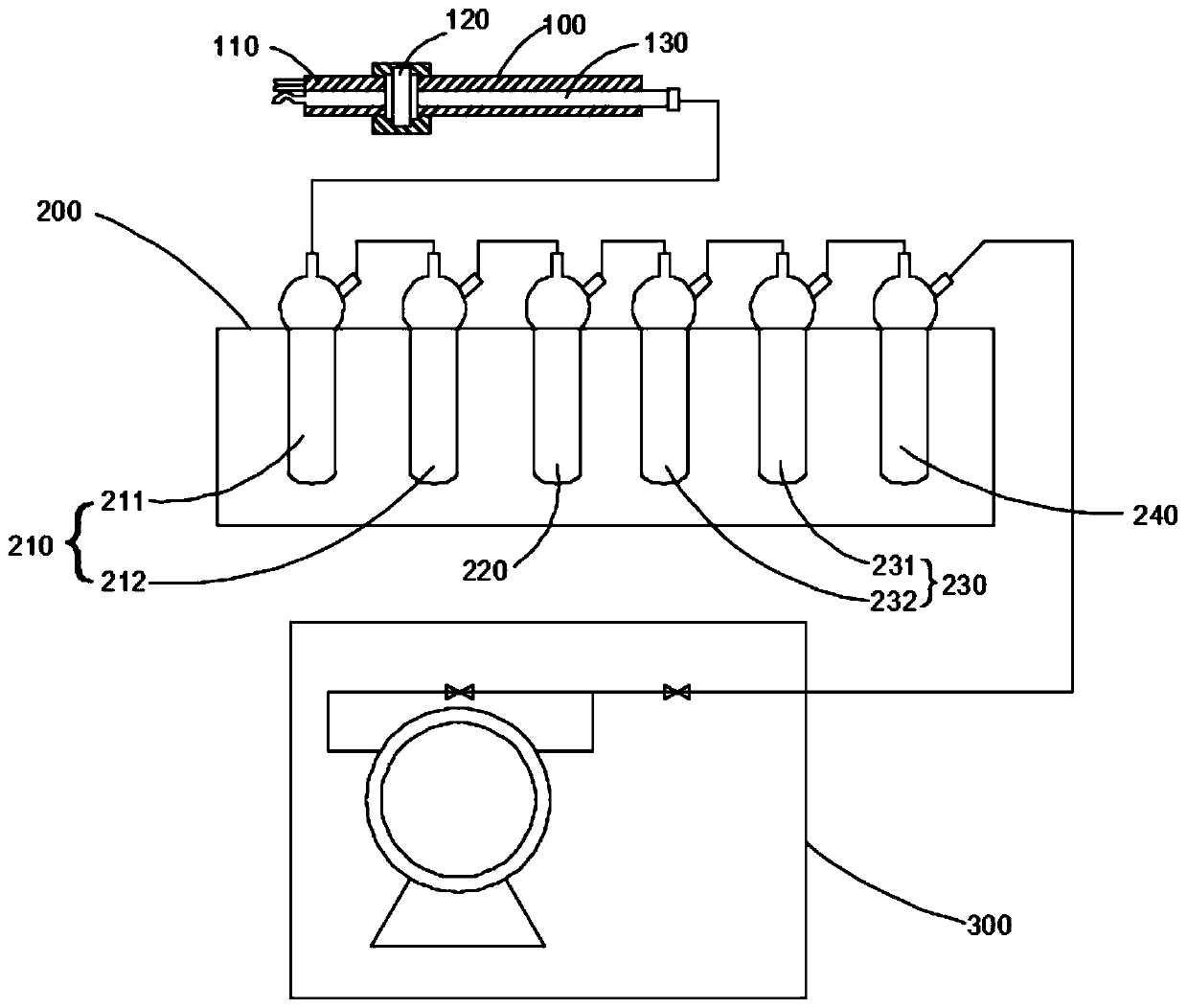

[0048] The method for detecting the content of particulate matter and heavy metal elements in the exhaust gas of the above-mentioned device comprises the following steps:

[0049] S1: Connect the sampling device to ensure that 200 mL of nitric acid solution with a mass concentration of 4% is installed in the nitric acid solution absorption bottle 211, and that 200 mL of a hydrogen peroxide solution with a mass concentration of 8% and permanganate are contained in the hydrogen peroxide solution absorption bottle 212. Potassium solution absorption bottle 231 is equipped with 200mL mass concentration of 3% potassium permanganate solution, sulfuric acid solution absorption bottle 232 is equipped with 200mL mass concentration of 8% sulfuric acid solution, check the air tightness of the device, sampling filter membrane 120 pre- After heating to 125°C, insert the sampling gun 100 vertically into the flue, set the sampling method to constant velocity sampling, and set the total samplin...

Embodiment 2

[0054] The method for detecting the content of particulate matter and heavy metal elements in the exhaust gas of the above-mentioned device comprises the following steps:

[0055] S1: Connect the sampling device to ensure that 200mL of nitric acid solution with a mass concentration of 6% is installed in the nitric acid solution absorption bottle 211, and that 200mL of a hydrogen peroxide solution with a mass concentration of 12% and permanganate are contained in the hydrogen peroxide solution absorption bottle 212. Potassium solution absorbing bottle 231 is equipped with 200mL mass concentration of 5% potassium permanganate solution, sulfuric acid solution absorbing bottle 232 is equipped with 200mL mass concentration of 12% sulfuric acid solution, check the air tightness of the device, sampling filter membrane 120 pre- After heating to 130°C, insert the sampling gun 100 vertically into the flue, set the sampling method to constant velocity sampling, and set the total sampling ...

Embodiment 3

[0060] The method for detecting the content of particulate matter and heavy metal elements in the exhaust gas of the above-mentioned device comprises the following steps:

[0061] S1: Connect the sampling device to ensure that 200mL of nitric acid solution with a mass concentration of 5% is installed in the nitric acid solution absorption bottle 211, and 200mL of a 10% hydrogen peroxide solution with a mass concentration of 10% in the hydrogen peroxide solution absorption bottle 212, permanganate The potassium permanganate solution that the mass concentration of 200mL is housed in the potassium solution absorption bottle 231 is 4%, and the sulfuric acid solution that the mass concentration of 200mL is housed in the sulfuric acid solution absorption bottle 232 is 10%. After heating to 120°C, insert the sampling gun 100 vertically into the flue, set the sampling method to constant velocity sampling, and set the total sampling volume to 1.5m 3 , when the cumulative sampling volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com