Dry distillation absorber for I-131 production

An absorber and dry distillation technology, which is applied in the field of radioisotope preparation, can solve the problems of radioactive iodine-131 vapor leakage, increase production equipment maintenance personnel, shorten service life, etc., and achieve compact structure, good safety and reliability, and production The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

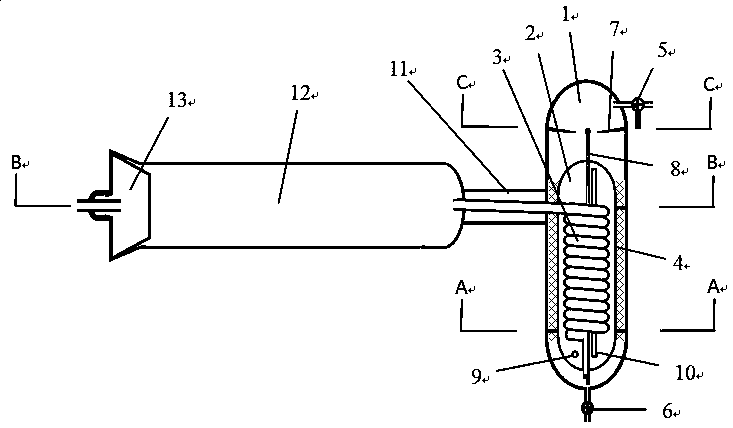

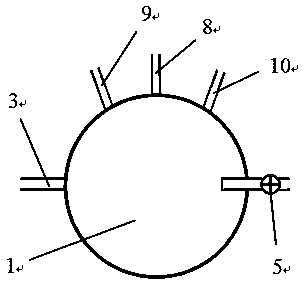

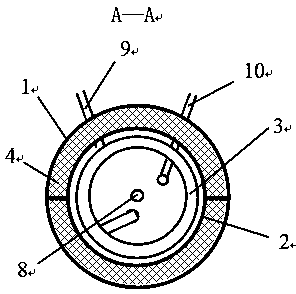

[0022] figure 1 It is a schematic diagram of the overall structure of a dry distillation absorber for I-131 production of the present invention, figure 2 It is a schematic plan view of the absorption tank in the present invention, image 3 It is the schematic diagram of the A-A sectional structure of the absorption tank in the present invention, Figure 4 Yes figure 1 B-B sectional structure diagram of the absorption tank in , Figure 5 It is a schematic diagram of the C-C sectional structure of the absorption tank in the present invention. exist Figure 1~Figure 5Among them, a dry distillation absorber for I-131 production of the present invention includes the dry distillation absorber including a vertically arranged absorption tank and a horizontally arranged distillation tube 12; wherein, the described absorption tank contains a lye tank 1 , water bath tank 2, coil pipe 3, one end of distillation tube 12 is bell mouth; The connection relation of above-mentioned retort...

Embodiment 2

[0027] The structure of this embodiment is the same as that of Embodiment 1, except that the angle between the oblique upward direction of the upper pipe of the coiled pipe 3 and the horizontal line is 10°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com