Improved method for stretching straightening of strip steel cold rolling and pickling

A technology of stretching straightening machine and strip steel, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of insufficient pickling, large consumption of rolls, and extension of straightening rolls, etc., to improve quality and production Efficiency, uniform wear, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

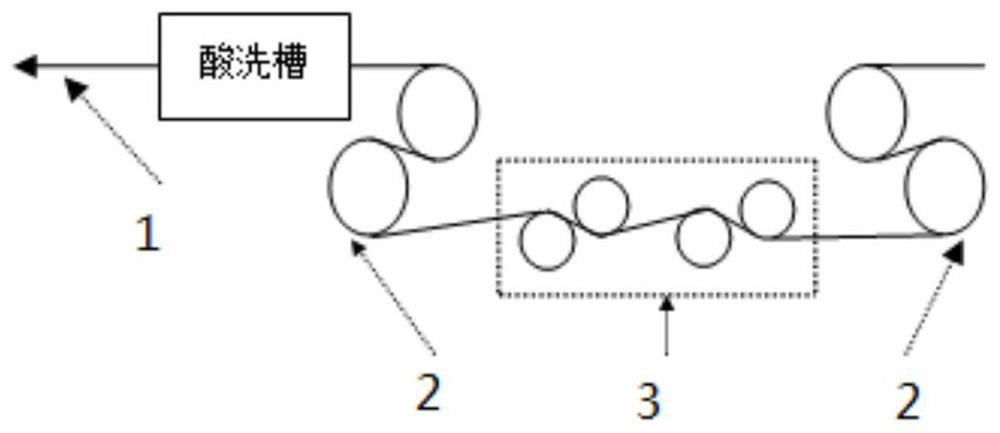

[0051] An improved method for stretching and straightening of cold-rolled pickled strip steel, which utilizes a stretching leveler to complete the stretching and straightening work, is characterized in that it comprises the following steps:

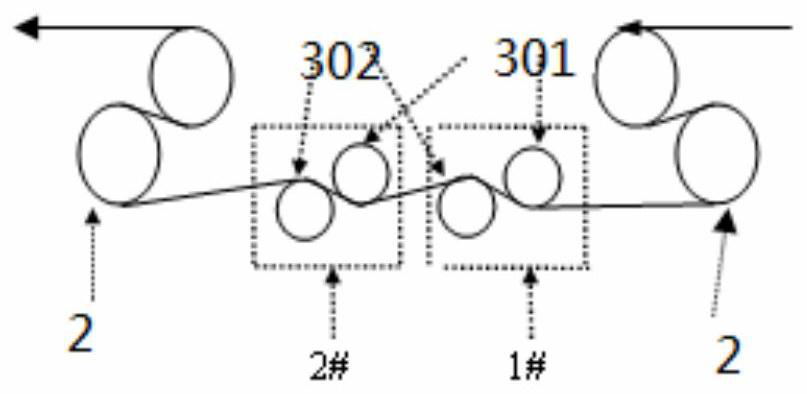

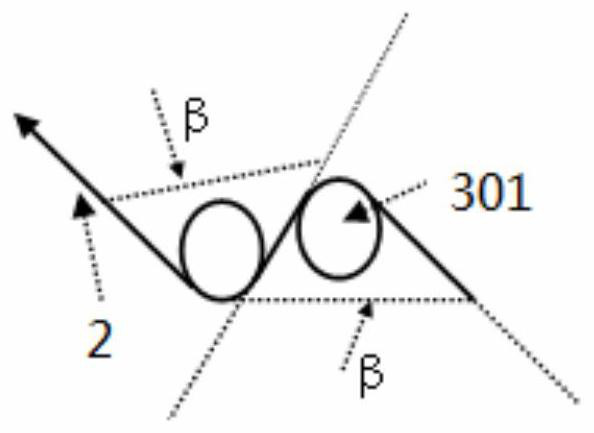

[0052] (1) if Figure 6 As shown, the upper work roll 301 and the lower work roll 302 of the stretch leveler 3 are changed from flat rolls to tapered rolls. The diameters of the two ends of the work rolls are 80mm at one end and 78mm at the other end. The spiral effect is applied to ensure that the work rolls The horizontal movement is smooth, and the upper and lower work rolls of the same unit are arranged with the big or small ends facing each other. This arrangement is for the balance of the force on the strip 1 and the work rolls during production; the big ends of the upper and lower work rolls of the 1# unit The small heads of the upper and lower work rolls of unit 2# are opposite to each other. This arrangement is to ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com