A method and device for controlling the rotational speed of a hot blank discharging motor of a heating furnace in a rolling workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

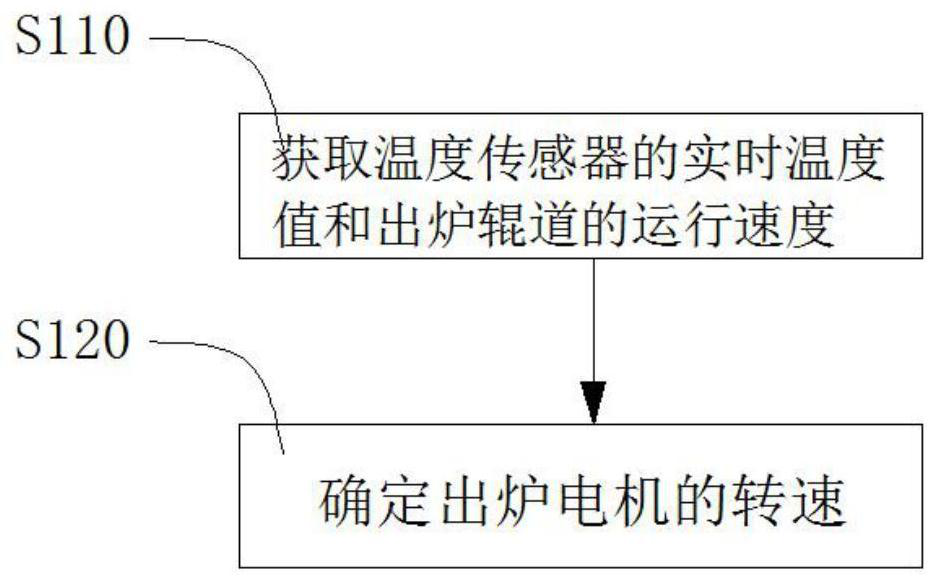

[0030] The invention discloses a method for controlling the rotational speed of a hot-blank discharging motor of a heating furnace in a rolling workshop. figure 1 As shown, the following steps are included: S110, obtain the real-time temperature value m of the temperature sensor and the running speed v of the discharging roller table; wherein, the temperature sensor is installed on the hot blank discharging roller table of the heating furnace, and the temperature sensor is installed on the hot blank discharging roller table of the heating furnace, and is connected to the outlet of the heating furnace. The distance d is greater than the length d of the billet 钢坯 ; S120, according to the real-time temperature value m and the running speed v to determine the speed of the motor.

[0031] In the present invention, by acquiring the real-time tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com