Non-fried automatic control food production device

A technology of automatic control and production equipment, applied in food ovens, food science, baking, etc., can solve the problems of lower baking efficiency, uneven bread color, and affecting taste, so as to improve efficiency, uniform heating, and improve eating taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

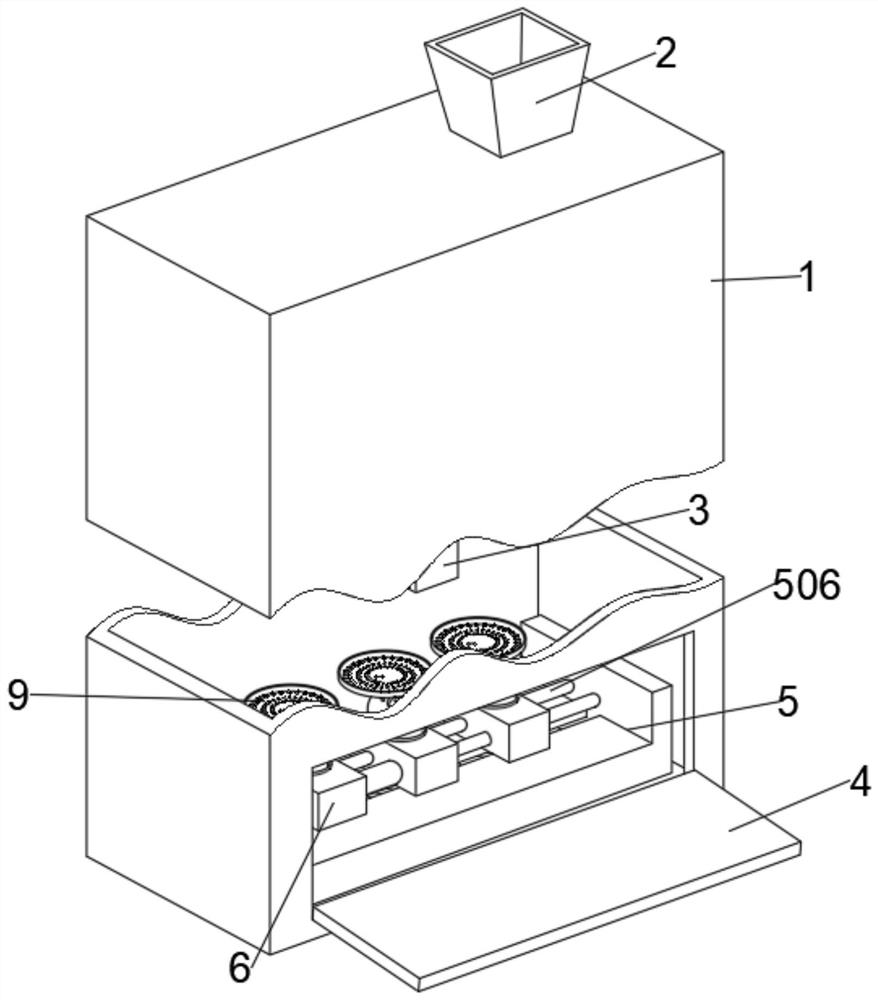

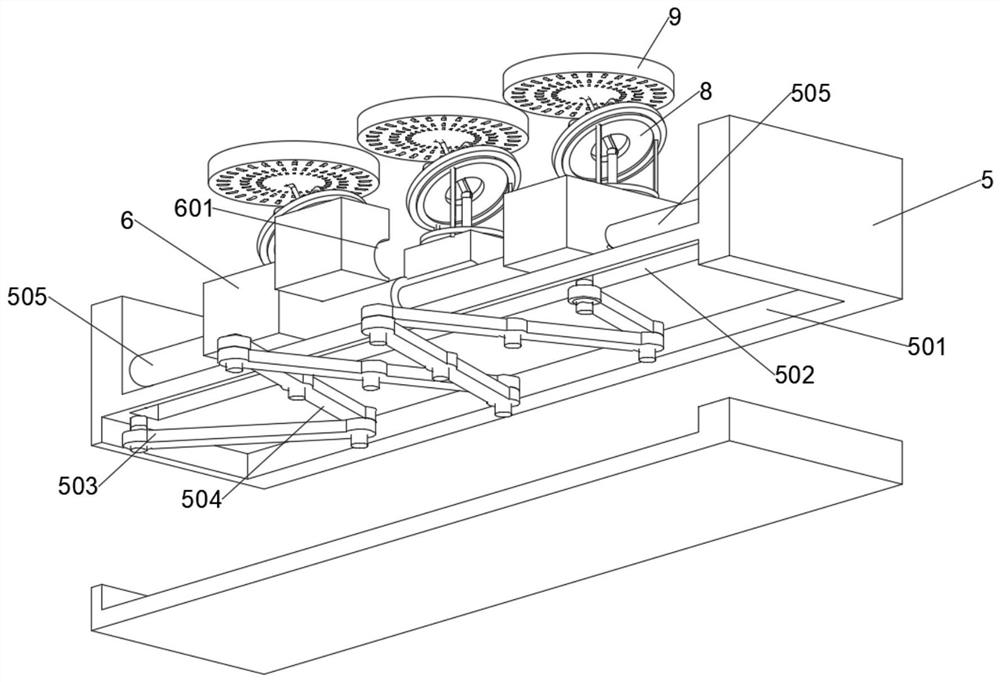

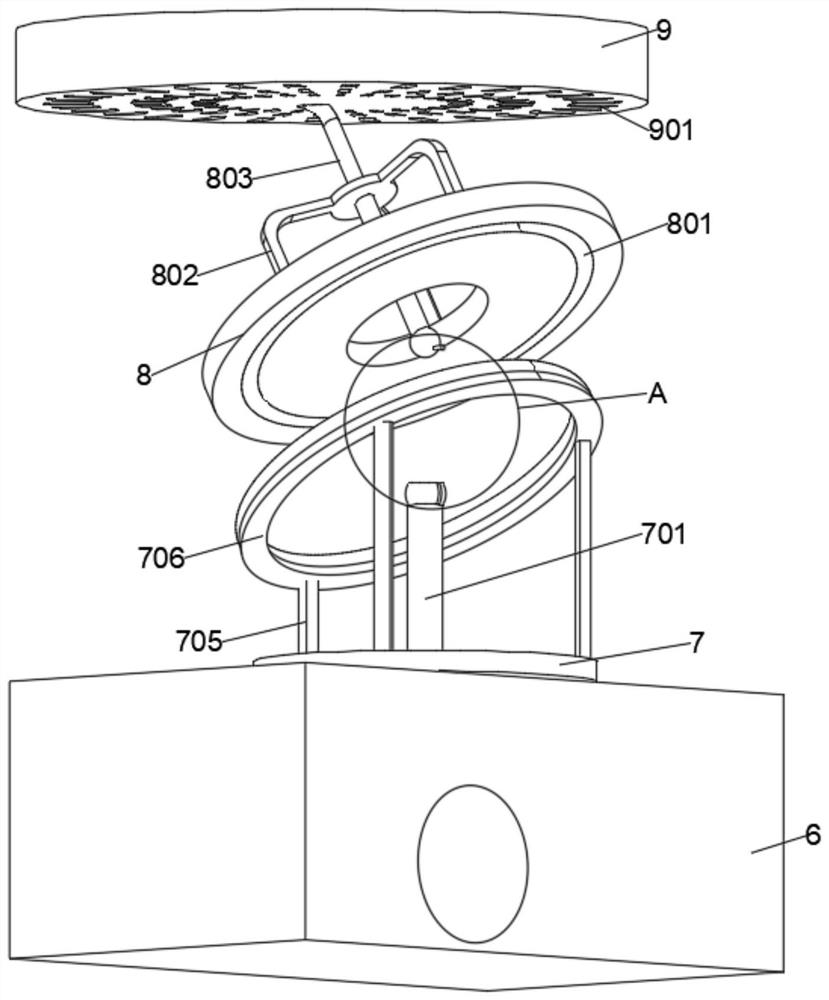

[0026] see Figure 1-6 , the present invention provides a kind of technical scheme:

[0027]A food production device for non-fried automatic control, comprising a food processing box 1, a feed hopper 2 is provided on the upper side of the food processing box 1, a forming discharge pipe 3 is provided in the middle of the food processing box 1, and the food processing box There is a box door 4 hinged on the lower front side of the body 1, and a pot plate 5 is fixed on the lower side inside the food processing box body 1. A square groove 501 is opened inside the bottom side of the pot plate 5, and a through groove 502 is opened in the middle of the upper wall of the square groove 501. The left side of the square groove 501 is rotatably connected with a support rod 503 through a pin shaft, and the right side of the support rod 503 is rotatably connected with a plurality of connecting rods 504 through a pin shaft. The rear end is provided with a sliding bar 506, and the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com