Indoor whole glass-ceramic anti-skidding blind road plate and method for manufacturing the same

A technology of glass-ceramic and its manufacturing method, which is applied in the direction of roads, roads, building structures, etc., can solve the problems of poor anti-skid performance of glass-ceramic plates, high production cost, and many processing procedures, and achieve good anti-skid coefficient and save raw materials , Reduce the effect of processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

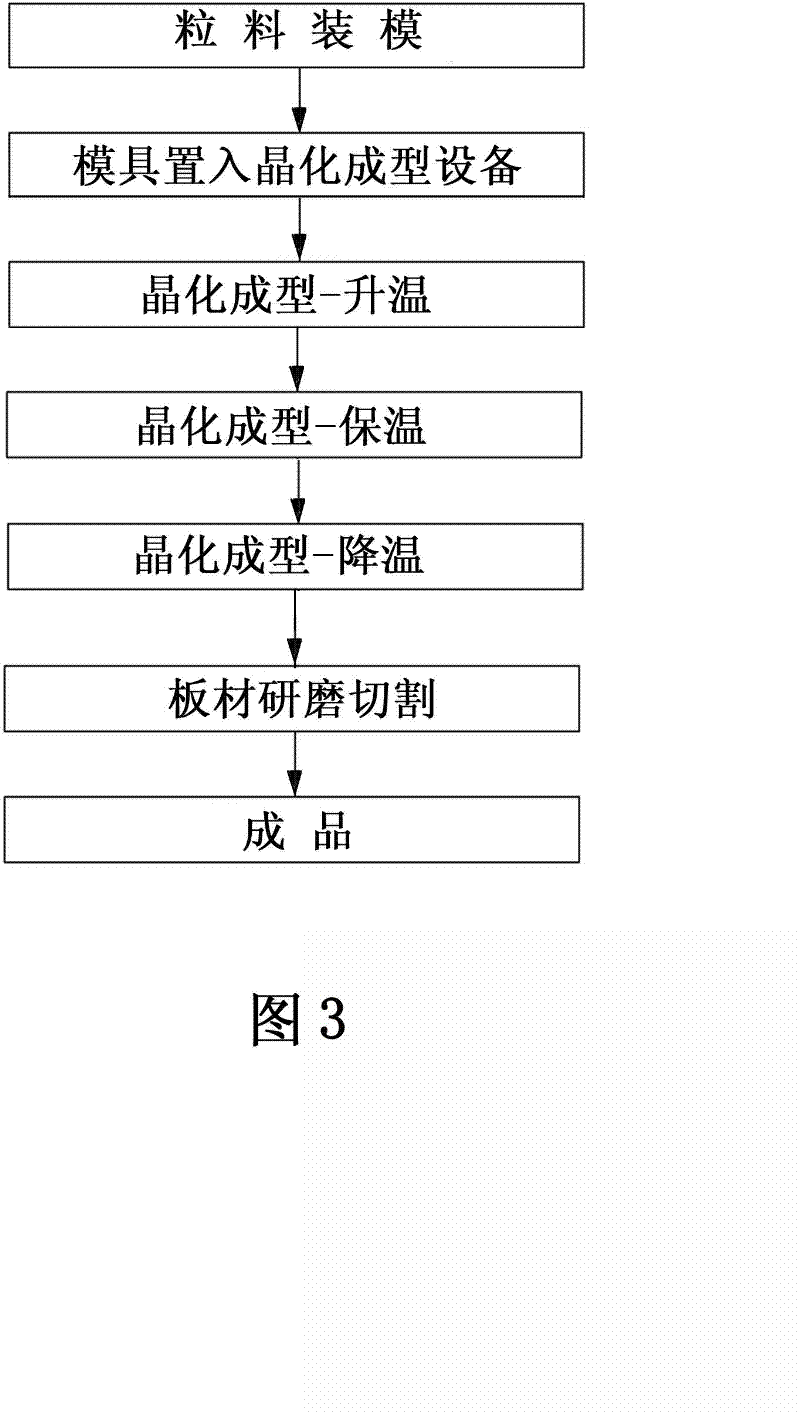

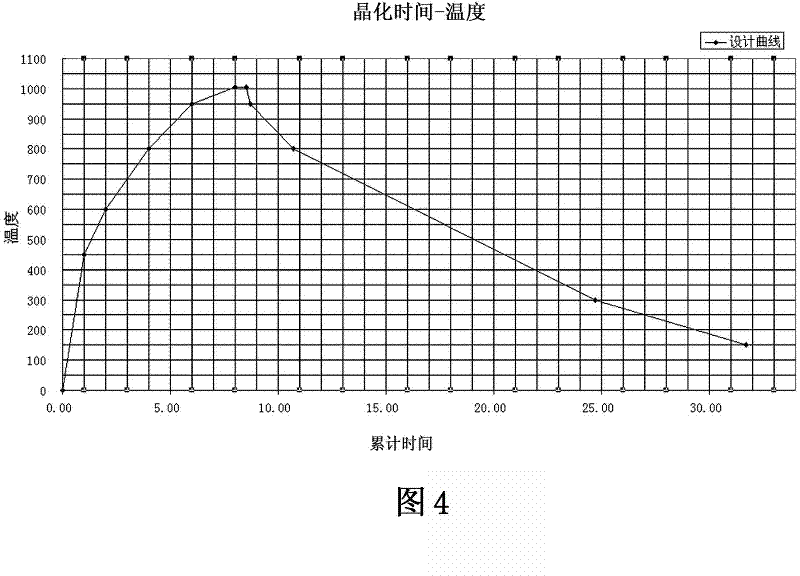

[0068] This kind of indoor whole-body glass-ceramic non-slip blind walkway board is made of glass-ceramics granules fired at a temperature above 1500°C. The glass granules 1 and the bottom glass-ceramic granules 2 are bonded by two filler crystallizations. Among them, the surface layer of glass-ceramic pellets is 1.5kg, the bottom layer of glass-ceramic pellets is 3kg, the fineness of the bottom layer of glass-ceramic pellets is 10-18 mesh, and the fineness of the surface layer of glass-ceramic pellets is 4-10 Mesh, and the 4-6 mesh uniform granules in the surface layer of glass-ceramic granules correspond to 30%-35%. When firing, operate according to the crystallization heating curve, and finally make 110 mesh (the number of particles per square inch is 110), and the specification is 300×300×18mm full-body glass-ceramic non-slip blind walkway board.

[0069] see figure 1 , this indoor full-body glass-ceramic non-slip tactile walkway board has strip-shaped protrusions 3 on i...

Embodiment 2

[0078] This kind of indoor whole-body glass-ceramic non-slip blind walkway board is made of glass-ceramics granules fired at a temperature above 1500°C. The glass granules 1 and the bottom glass-ceramic granules 2 are bonded by two filler crystallizations. Among them, the surface layer of glass-ceramic pellets is 3kg, the bottom layer of glass-ceramic pellets is 6kg, the fineness of the bottom layer of glass-ceramic pellets is 10-18 mesh, and the fineness of the surface layer of glass-ceramic pellets is 4-10 mesh , and the 4-6 mesh uniform particles in the surface layer of glass-ceramic particles account for 35%-40%; when firing, operate according to the crystallization heating curve, and finally make 115 mesh (the number of particles per square inch is 115 ), the size is 400×400×20mm full-body glass-ceramic non-slip blind road board.

[0079] The mold used for the crystallization molding of the indoor full-body glass-ceramic anti-slip blind passage can adopt the following tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com