Construction method of reinforced concrete structure by using profile steel to replace part of steel bars

A reinforced concrete and construction method technology, applied in the direction of building structure, structural elements, building components, etc., can solve the problems of affecting work efficiency, inability to accurately locate, and difficulty in ensuring uprightness, so as to reduce the demand for skilled labor and increase the overall Stability, save painting and decoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

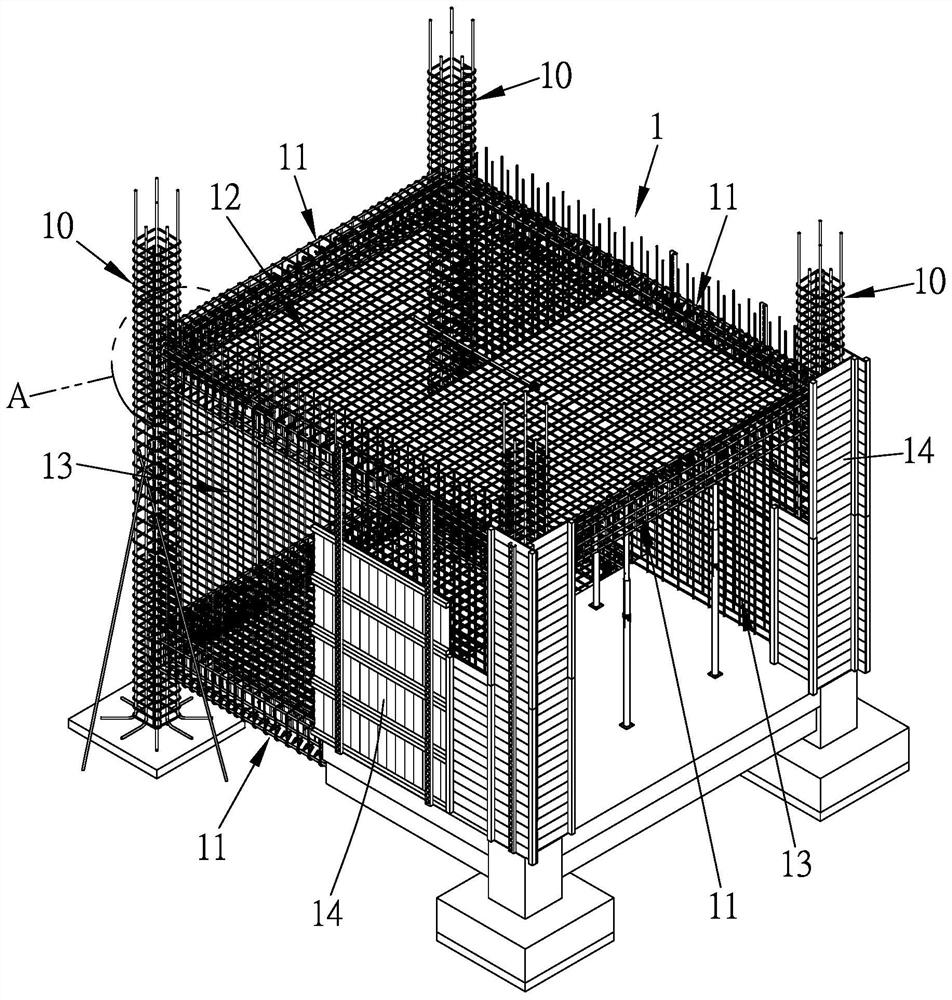

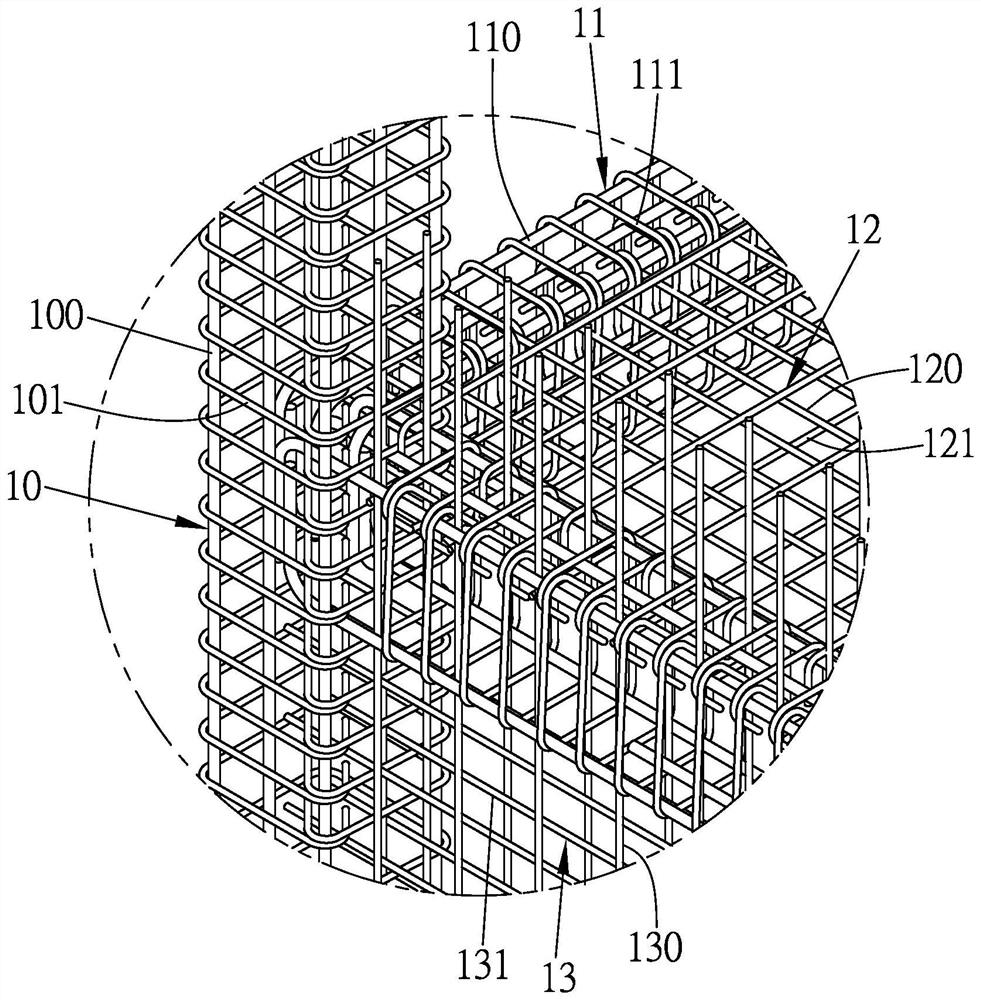

[0099] Relevant present invention is for reaching above-mentioned purpose of use and effect, the technical means that adopts, presents preferred feasible embodiment hereby, and cooperates as shown in the drawing, is described in detail as follows:

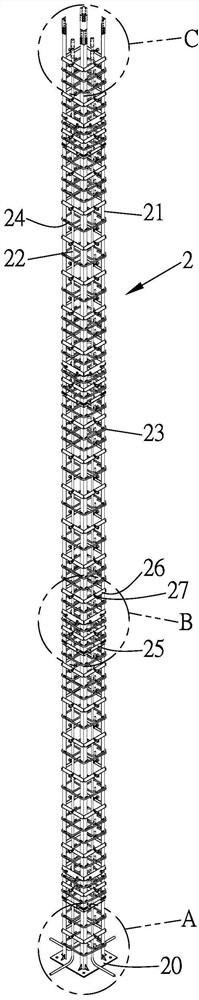

[0100]The steel bar structure of the RC structure of the present invention is mainly a structural member that replaces part of the steel bar with section steel, which is called a "stiffening member" to distinguish the existing steel bar member, and the stiffening member can be produced in the factory first and then transported to On-site assembly and construction.

[0101] For embodiments of each stiffening member of the present invention, please refer to Figure 2A ~ Figure 13 As shown, the stiffening member of the present invention is divided into a column stiffening member 2, a beam stiffening member 3, a wall stiffening member 4 and a plate stiffening member 5, etc., wherein the column stiffening member 2 is provided with a col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com