Advanced drilling machine control system

A control system and advanced drilling rig technology, applied in the automatic control system of drilling, rotary drilling rig, drilling pipe, etc., can solve the problems of single drilling method, inability to adjust the drilling speed and drilling torque, and reduce the The effect of work intensity and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

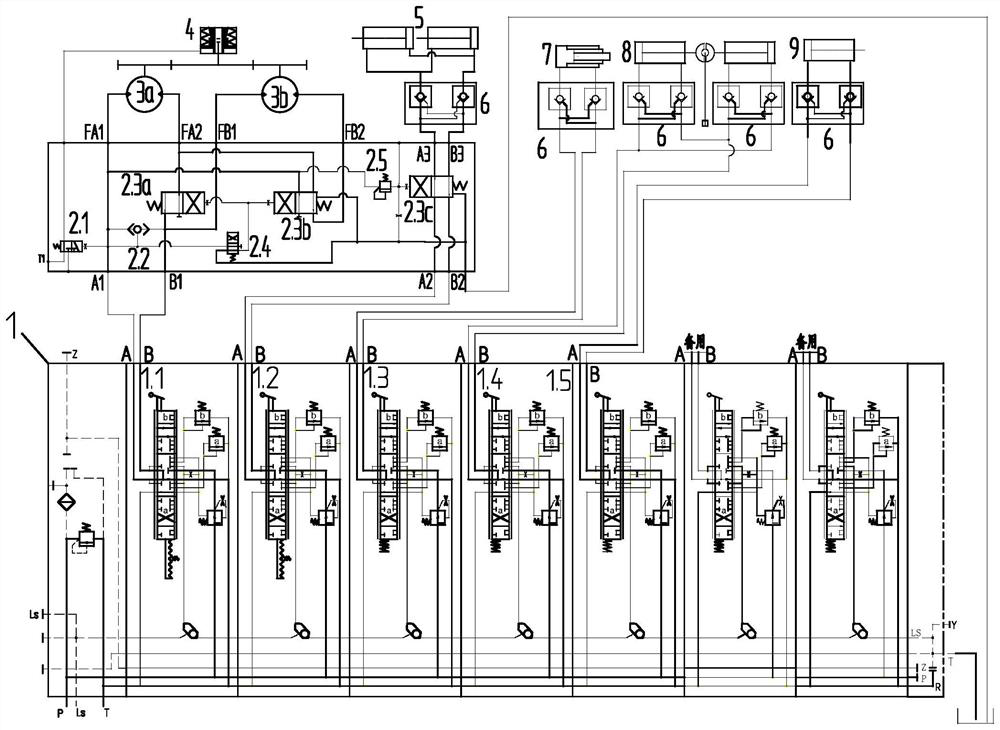

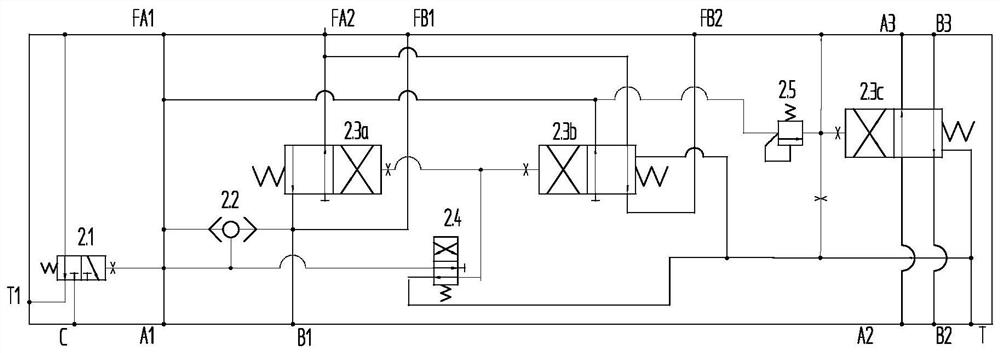

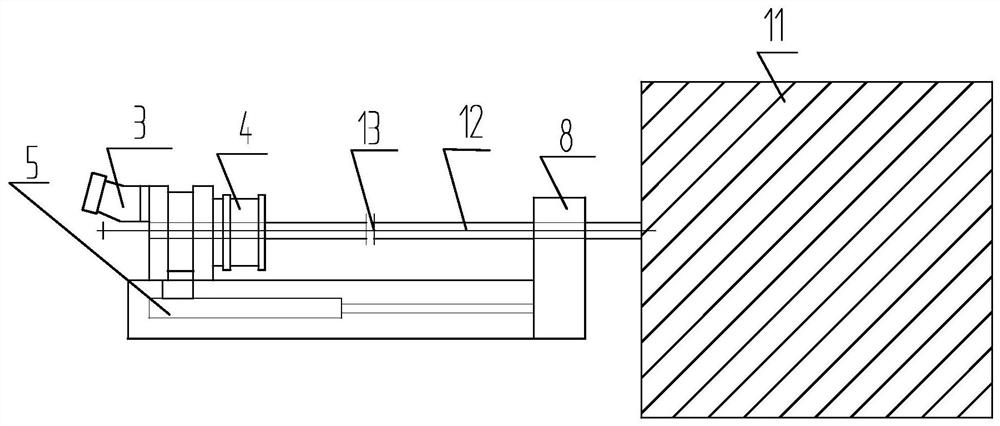

[0023] refer to figure 1 , a leading drilling rig control system, including a multi-way valve 1, a first hydraulic motor 3a, a first reversing valve 2.3a, a second reversing valve 2.3b, a second hydraulic motor 3b, a third reversing valve 2.1, a hydraulic Chuck 4, fourth reversing valve 2.4, fifth reversing valve 2.3c and feed cylinder 5; the multi-way valve includes multiple working oil ports, and the first working oil port 1.1 of the multi-way valve passes through the first reversing valve Connected with the first hydraulic motor, the first working oil port is connected with the second hydraulic motor through the second reversing valve, the first reversing valve is connected with the second reversing valve, the first working oil port is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com