Combined type device and method for measuring drilling depth

A drilling depth, combined technology, applied in drilling equipment and methods, measurement, drill pipe and other directions, can solve problems such as drill pipe sticking, increase work costs, affect labor efficiency, etc., to ensure accuracy and real-time performance , to ensure the effect of accuracy and authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

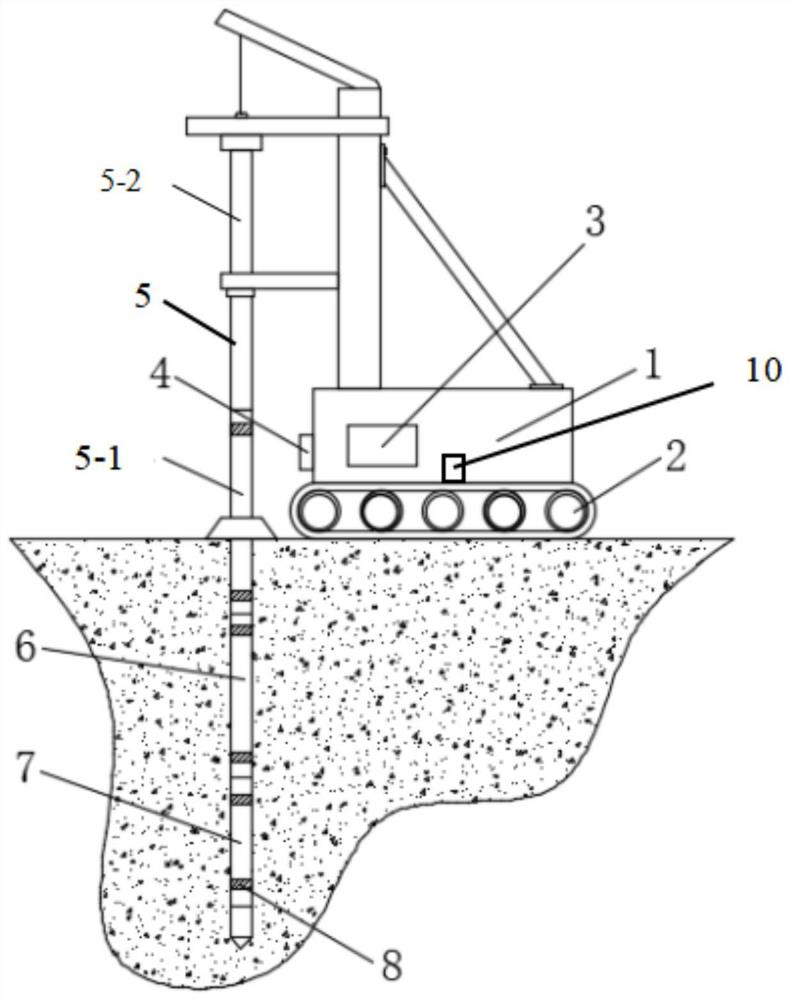

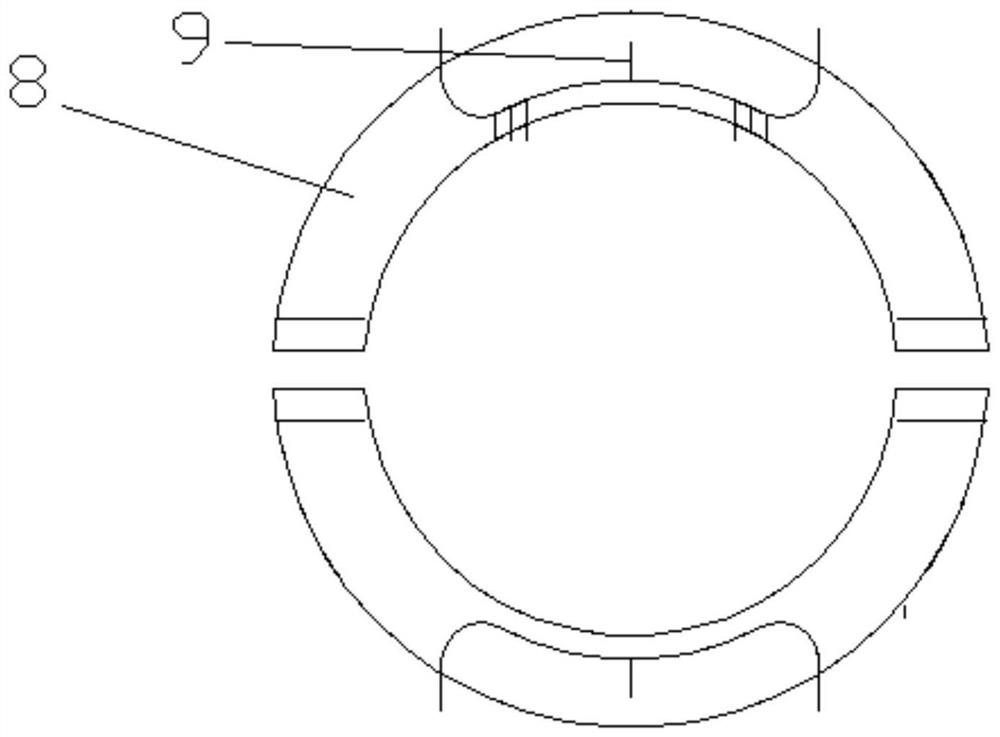

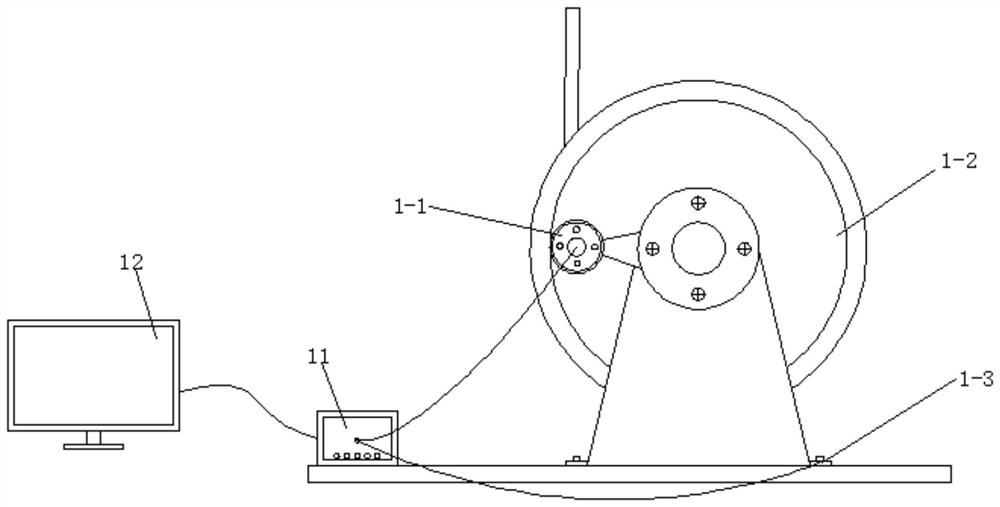

[0035] Such as Figure 1-3 As shown, a combined device for measuring the depth of a borehole includes a drilling rig body 1 and a crawler belt 2, an electronic meter counter 1-1 and a drilling rig hoisting shaft wheel 1-2 are arranged on the drilling rig body 1, and the drilling rig body 1 is provided with a positioning system module 10 at the bottom, and an integrated acquisition instrument 3 is provided on the front of the drilling rig body 1. The integrated acquisition instrument 3 is electrically connected to a data center, and the data center is electrically connected to the cloud platform. The drilling rig body 1 The base is equipped with a radio frequency coil 4, the radio frequency coil 4 can sense the passing of the metal buckle 8, the metal buckle 8 is installed on the drill pipe 5, and the active drill pipe 5-2 is installed above the drill pipe 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com