A main pump maintenance method

A main pump and motor shaft technology, applied in the field of main pump maintenance, can solve the problems such as the inability of the shaft seal water to be put into operation, the water level of the primary circuit is lowered, and the dose of irradiation is large, so as to optimize the maintenance period of the main pump, save maintenance costs, and reduce The effect of human bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, objects and effects of the present invention, specific embodiments of the present invention are described in detail with reference to the accompanying drawings.

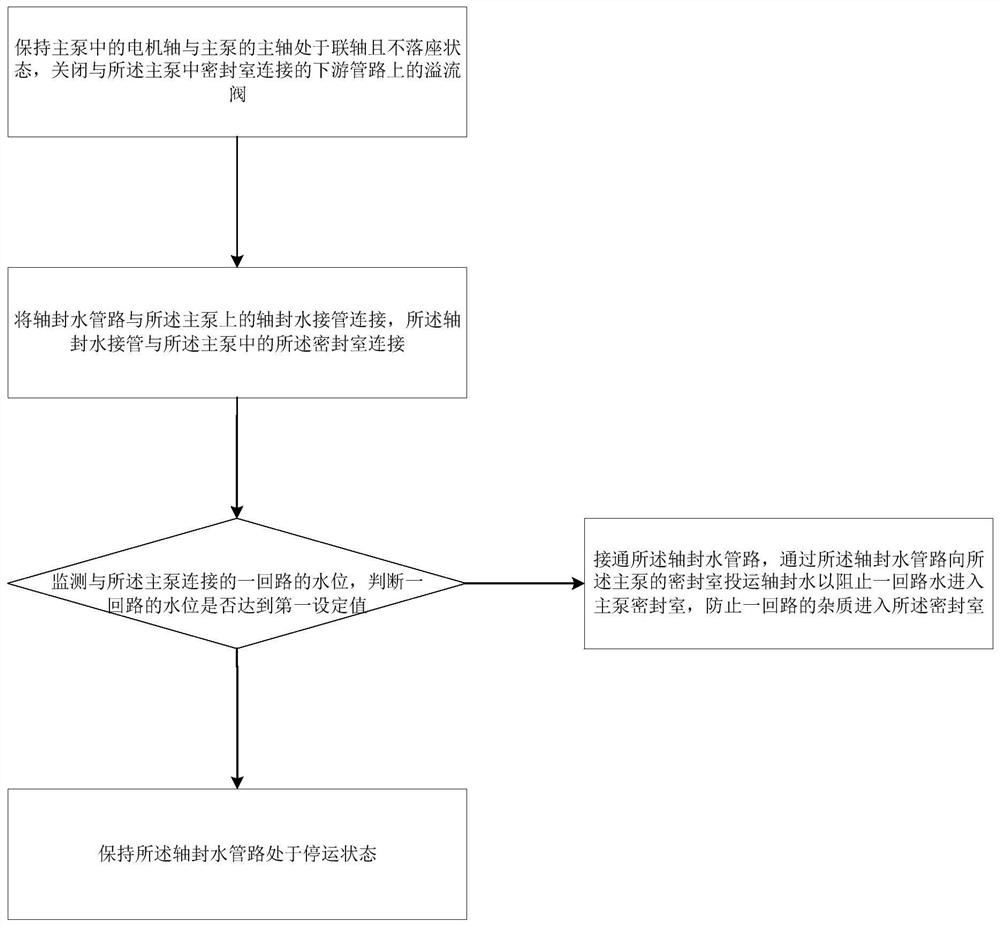

[0037] Figure 1 Some preferred embodiments of the main pump overhaul method of the present invention are shown. The main pump maintenance method cancels the main pump seating and shaft lifting, simplifies the process, optimizes the main pump maintenance period during the overhaul, reduces human deviation, saves maintenance costs, saves spare parts, reduces labor costs, saves critical paths, and reduces the risk of maintenance equipment.

[0038] as Figure 1 As shown, the master pump overhaul method includes the following steps:

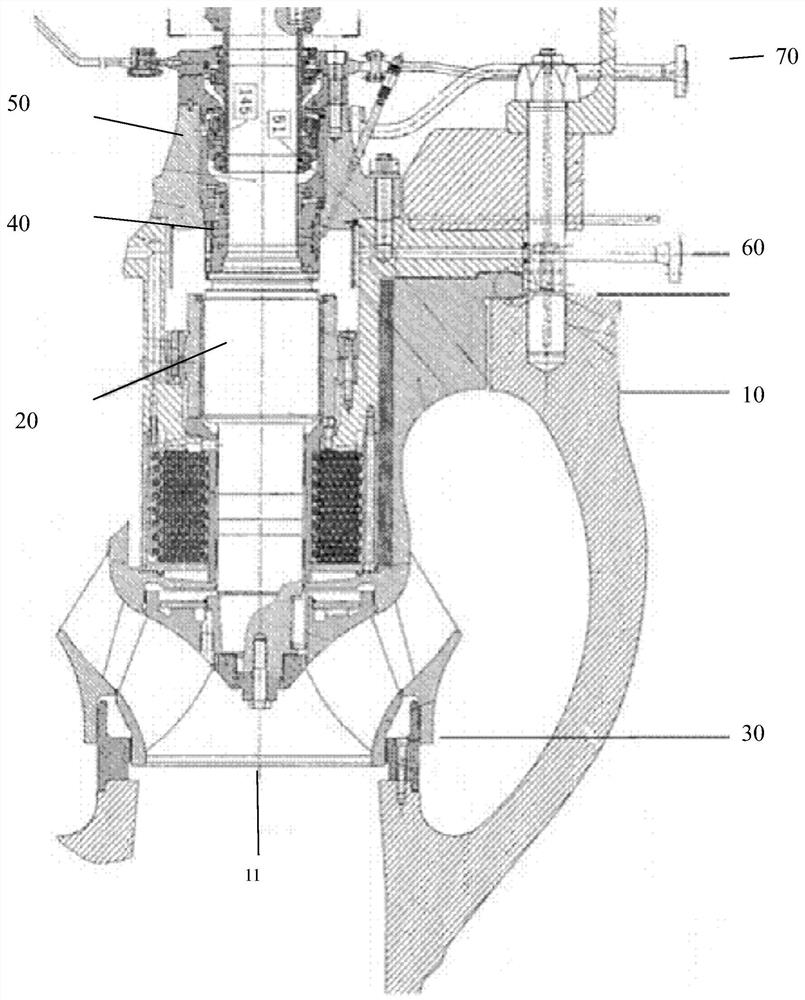

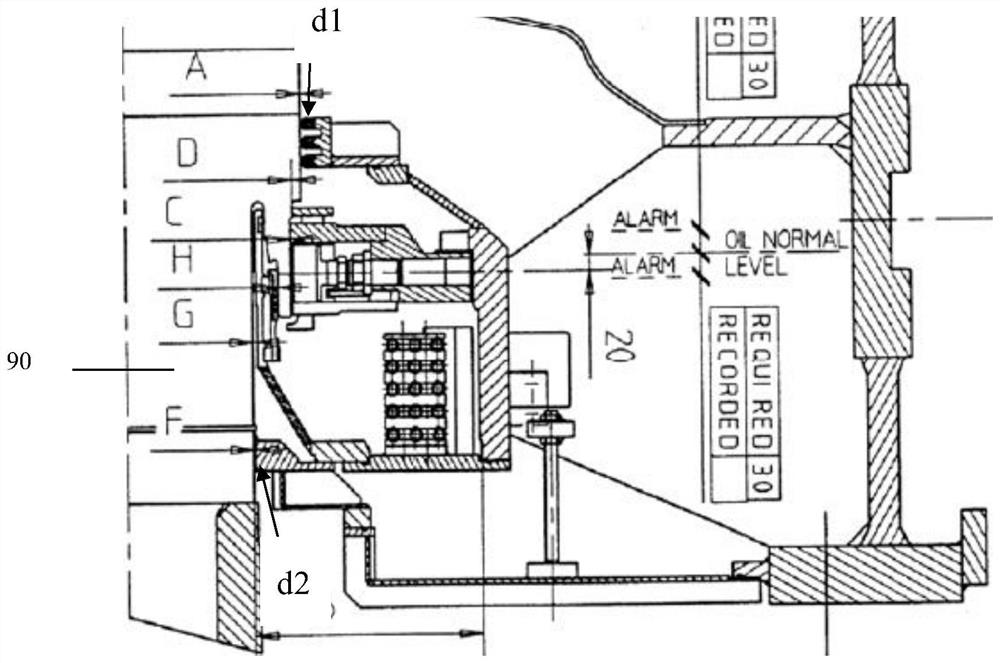

[0039] Keep the motor shaft in the main pump and the spindle of the main pump 20 in a coupling and not seated, close the relief valve on the downstream pipeline connected to the sealing chamber 50 of the main pump. Where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com