A double ball bowl joint oil pipe assembly detection method

An assembly detection and ball joint technology, which is applied in the direction of charging system, fuel injection device, manufacturing tools, etc., can solve the problem that there is no patent to provide double ball joint oil pipe assembly detection process and method, so as to ensure safe, stable and efficient operation , Optimize the maintenance period and reduce the effect of repeated maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technology of the present invention is further described below:

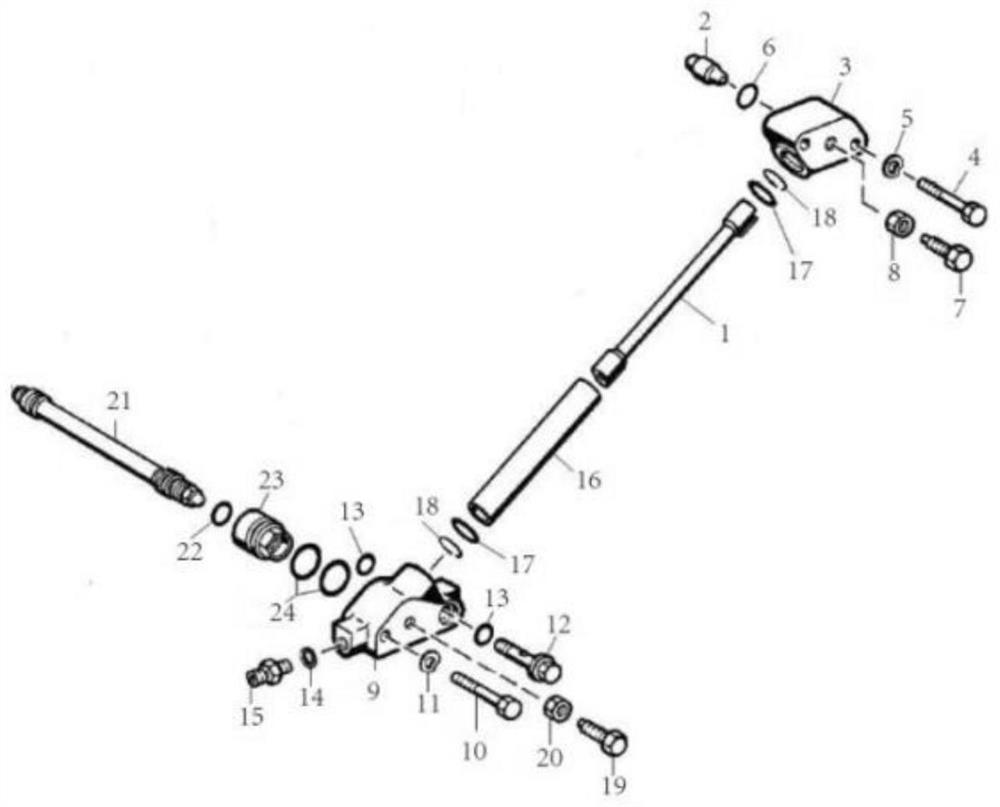

[0029] Such as figure 1 As shown, a high-pressure circuit of a fuel system is mainly composed of a fuel injection pump, a high-pressure fuel pipe 1, a fuel supply pipe 21, and a fuel injector, wherein the fuel injection pump and the fuel injector are connected through the fuel supply pipe 21 and the high-pressure fuel pipe 1.

[0030] The high-pressure oil pipe 1 adopts a double ball bowl joint oil pipe structure. The high-pressure oil pipe 1 is provided with an oil pipe sleeve 16. The two together form an oil pipe assembly. The upper end of the oil pipe assembly is installed in the flange block A3 and connected with the ball joint 2. The lower end of the oil pipe assembly Installed into the flange block B9 and connected with the spherical joint of the oil supply pipe 21, the two ends of the oil pipe assembly are sealed with the flange blocks A3 and B9 through the sealing ring C17, and the sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com