Hollow rolling driving mechanism for low-temperature environment

A driving mechanism and low-temperature environment technology, which is applied in the field of wind tunnel testing, can solve problems such as transmission accuracy being affected by backlash, low transmission efficiency, and failure of the driving device and bearing group.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

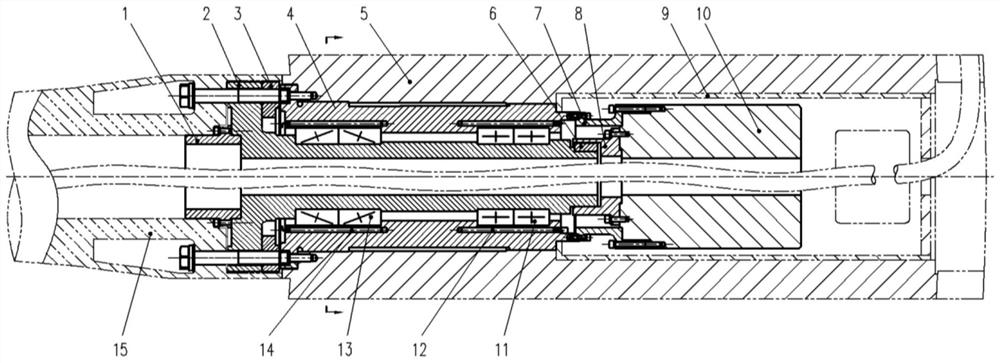

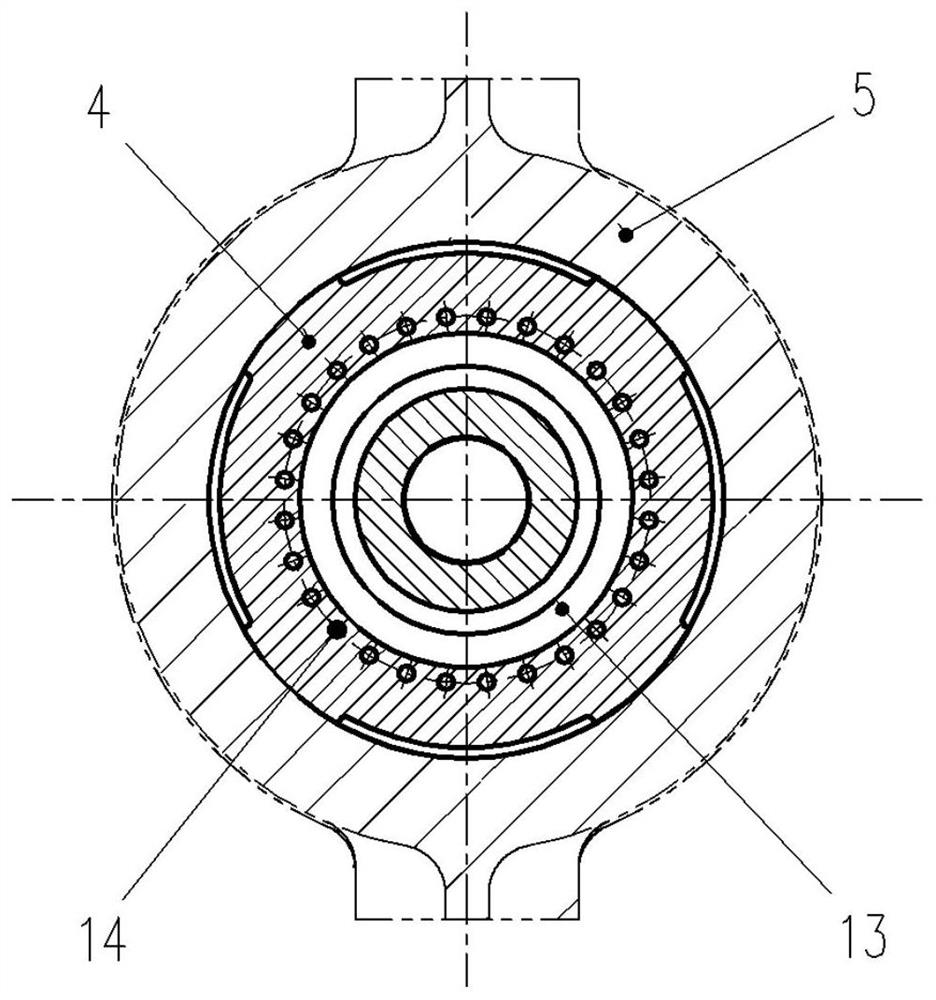

[0036] The outer diameter of the middle bracket 5 in this embodiment is Φ440mm and the length is 1500mm. The integrated actuator 10 is arranged in the inner cavity of the middle bracket 5, and a supporting device 15 is coaxially arranged along the front end of the middle bracket 5. The integrated actuator 10 and The supporting device 15 is connected by a connecting device arranged along the axis of the integrated actuator 10, and a heating rod group is also arranged inside the connecting device. The integrated actuator 10 drives the connecting device to rotate around the integrated actuator 10 along the axis, and drives the hollow rolling drive mechanism for low temperature environment to roll within the range of -180° to +180°.

[0037] The integrated actuator 10 has an integrated structure, and the required high-precision and high-torque transmission can be achieved through the connection of the following related parts, specifically:

[0038] The bearing block 4 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com