Auxiliary device for fatigue testing machine

A fatigue testing machine and auxiliary device technology, applied in the direction of measuring devices, using applied repetitive force/pulsation force to test material strength, instruments, etc., can solve problems such as overestimating the fatigue performance of structures and components, accidental failure of structures, and insufficient design calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

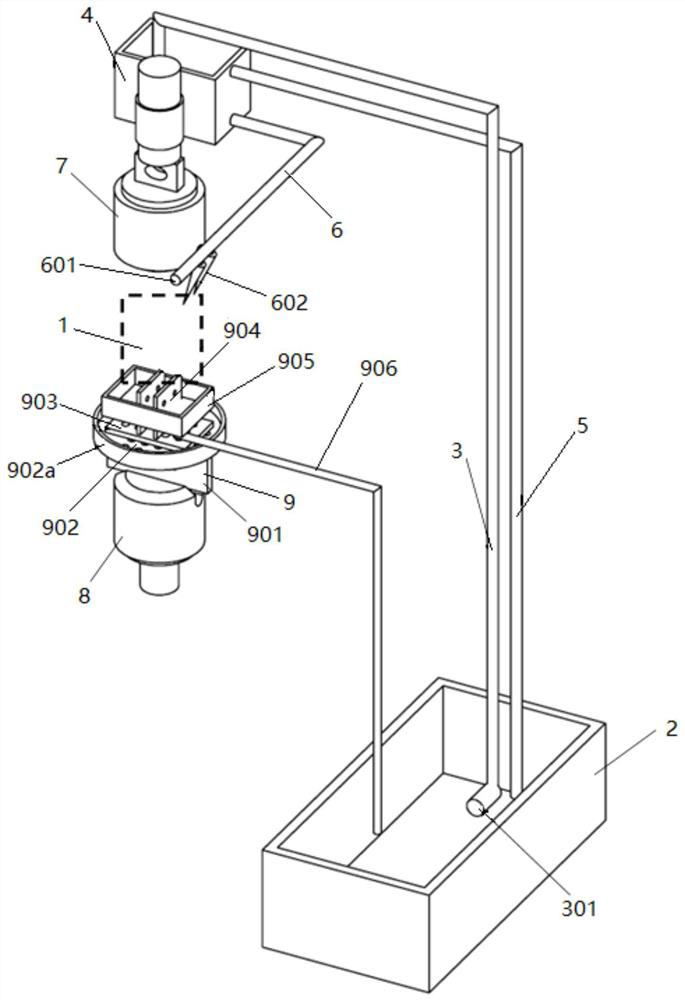

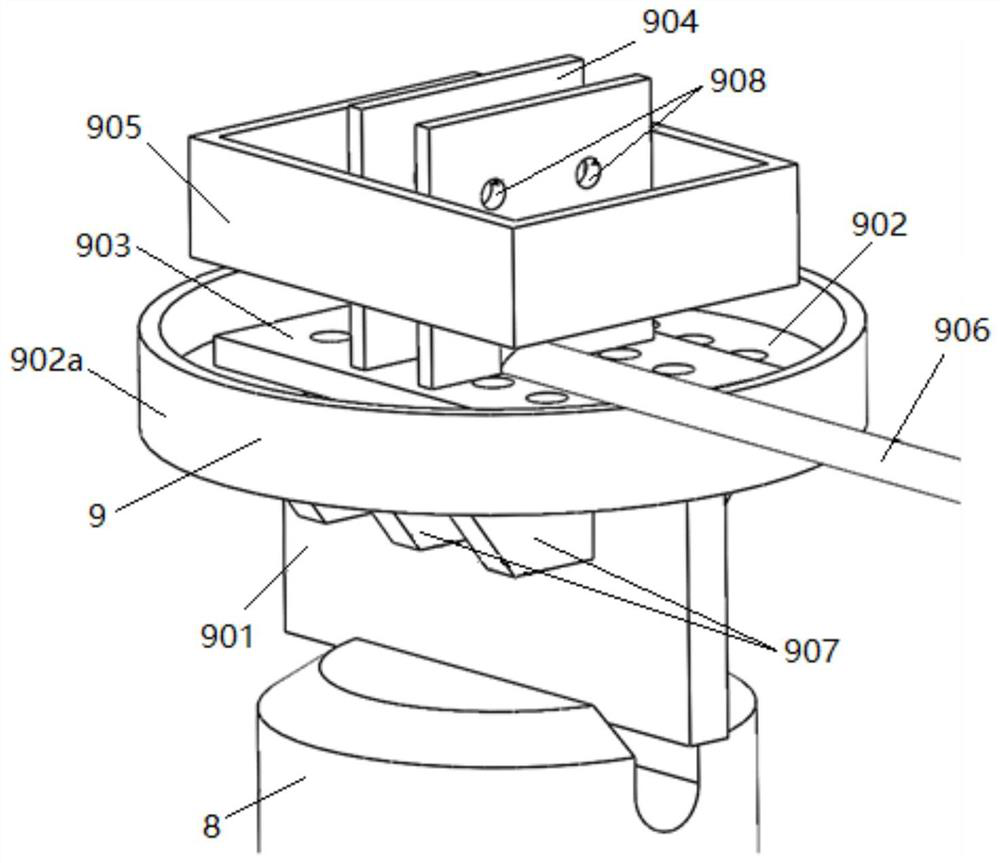

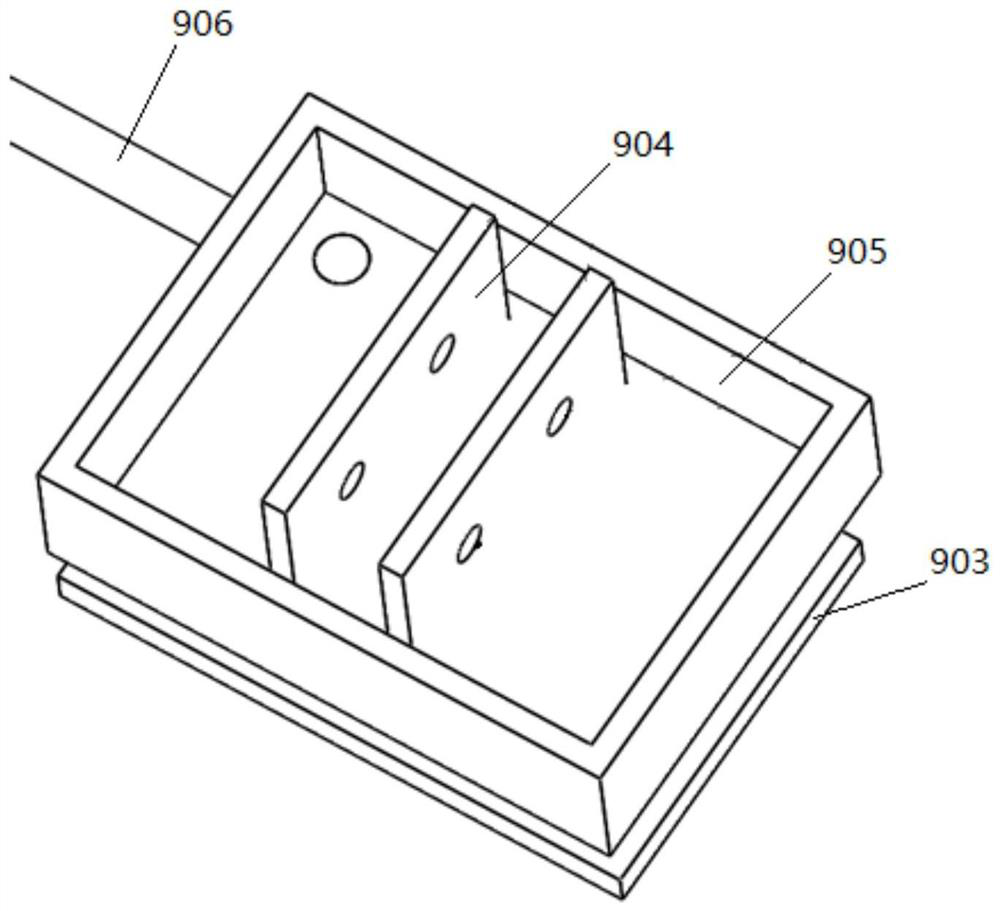

[0040] see Figure 1 to Figure 6 , the figure shows the auxiliary device for fatigue testing machine of the present invention, the fatigue testing machine (not shown in the figure) is provided with the upper chuck 7 of the testing machine and the lower chuck 8 of the testing machine, and the lower chuck 8 of the testing machine is located on the testing machine Directly below the chuck 7, the test piece 1 is arranged on the auxiliary device, and the auxiliary device includes:

[0041] a bottom tank 2;

[0042] A water suction pipe 3, one end of the water suction pipe 3 is located in the bottom water tank 2, and one end of the water suction pipe 3 is connected to a water pump 301 located in the bottom water tank 2;

[0043] A top water tank 4, the top water tank 4 is higher than the bottom water tank 2, and the other end of the suction pipe 3 is located in the top wat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap