Ultrasonic guided wave nondestructive testing device and damage identification method for transmission conductor

A technology of ultrasonic guided waves and power transmission wires, which is applied in the generation of ultrasonic/sonic/infrasonic waves, the use of sound waves/ultrasonic/infrasonic waves to analyze solids, and the processing of detection response signals. It can solve misjudgment, low efficiency, and detection of casualties, etc. problem, to achieve the effect of improving detection efficiency and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

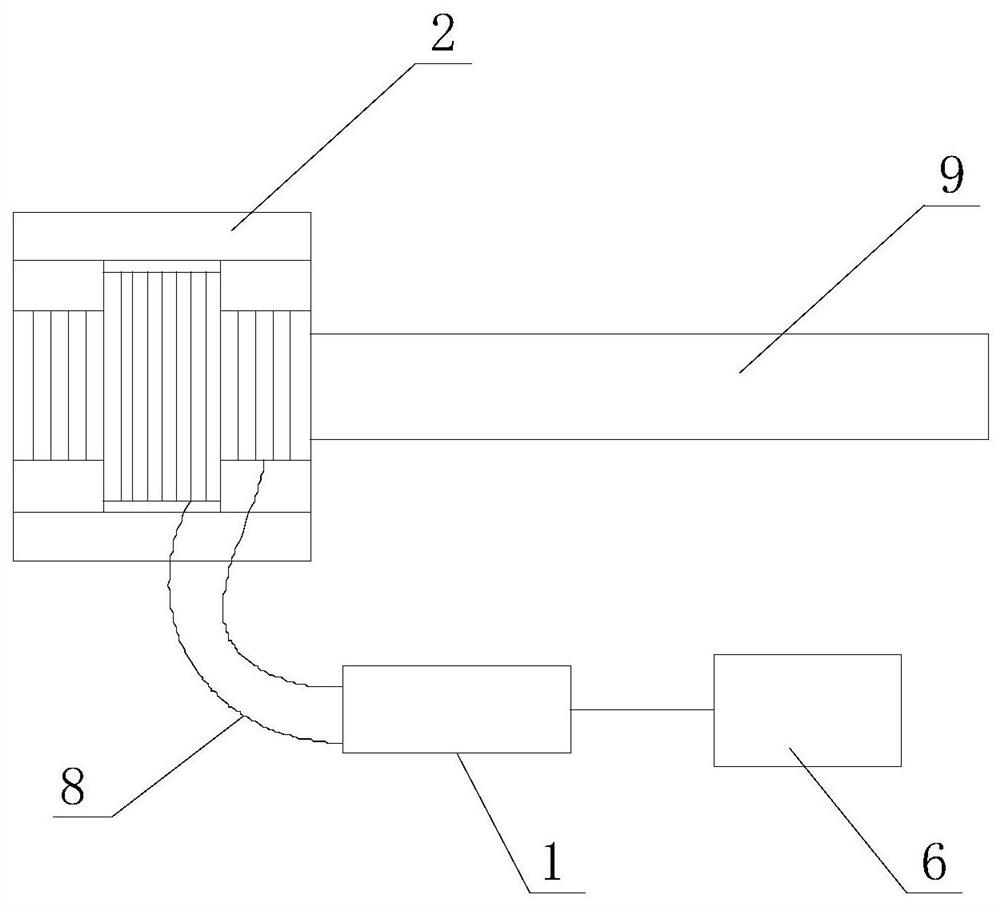

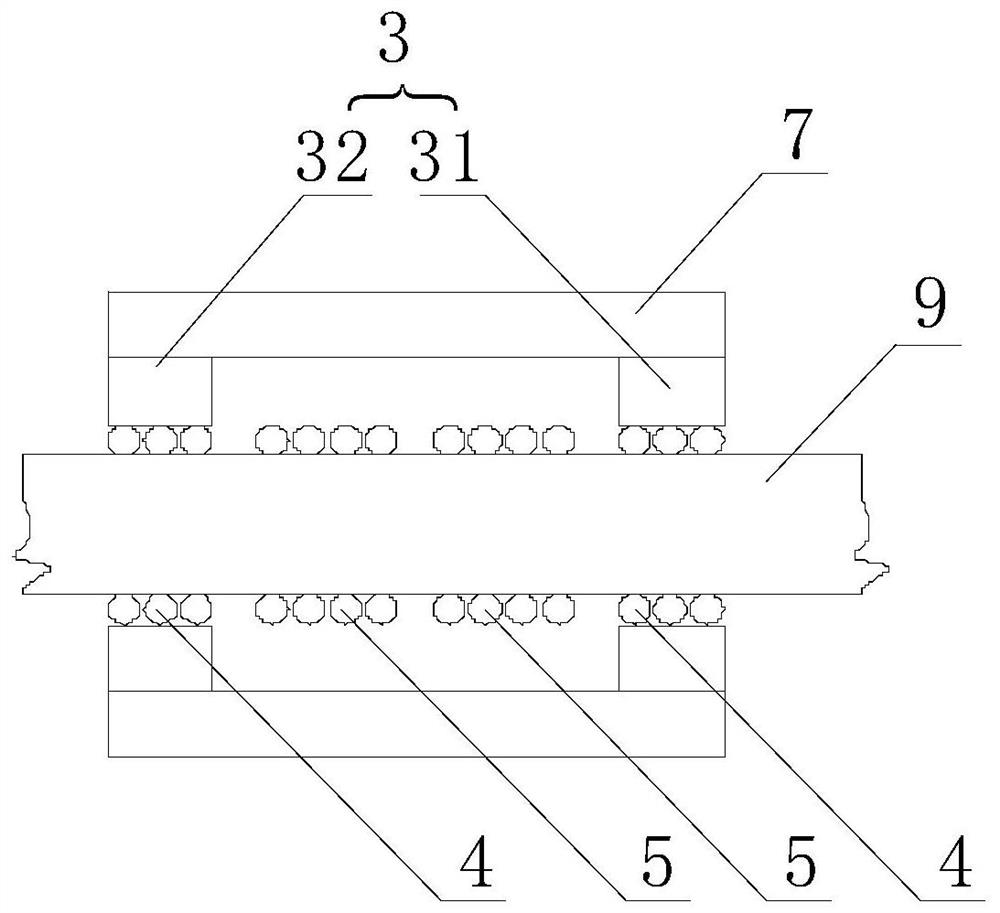

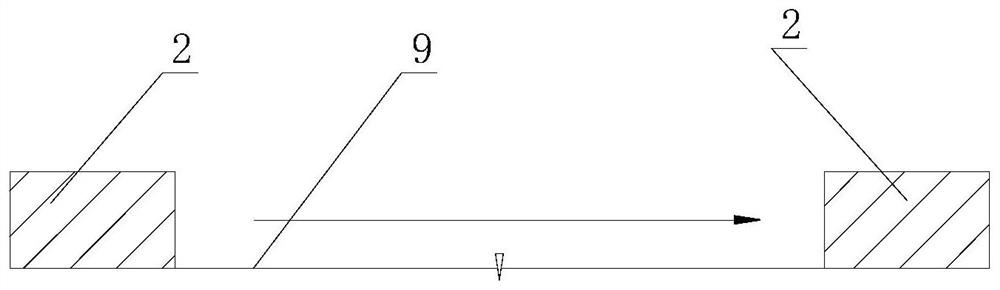

[0034] like figure 1 , figure 2 As shown, an ultrasonic guided wave non-destructive testing device for a power transmission wire includes a controller 1 and an ultrasonic guided wave detection assembly 2 installed on a power transmission wire 9. The ultrasonic guided wave detection assembly 2 includes a magnet 3 and is wound on a power transmission wire The first coil 4 and the second coil 5 on the wire 9, the first coil 4 and the magnet 3 form an electromagnetic ultrasonic guided wave detection mechanism for detecting the aluminum twisted wire structure layer of the power transmission wire 9, the second coil 5 and the magnet 3 form a Lorentz force ultrasonic guided wave detection mechanism for detecting the steel core structure layer of the transmission wire 9, and the electromagnetic ultrasonic guided wave detection mechanism and the Lorentz force ultrasonic guided wave detection mechanism both include excitation terminals and a receiving end, the receiving end is connecte...

Embodiment 2

[0040] This embodiment discloses a damage identification method for a power transmission wire, which is used to process the signal sent by the ultrasonic guided wave nondestructive testing device described in Embodiment 1. The damage identification method includes the following steps in sequence:

[0041] Step 1: Establish the waveform dictionary matrix of ultrasonic guided wave propagation for different materials and different propagation distances. The wave forms of guided wave propagation at different distances on the steel core are as follows Figure 5 As shown, the waveform vector d of different propagation distances is obtained m , and the waveform vectors of all propagation distances form a dictionary matrix D, where:

[0042]

[0043] in,

[0044]

[0045] Step 2: the dictionary matrix D that obtains based on step 1 carries out sparse Bayesian learning to the actually received signal y, and its linear model is: y=Dw, namely:

[0046]

[0047] Among them: y i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com