Electromechanical equipment fault positioning system

A technology for fault location and electromechanical equipment, which is applied in the measurement of electricity, measurement of electrical variables, and testing of machine/structural components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

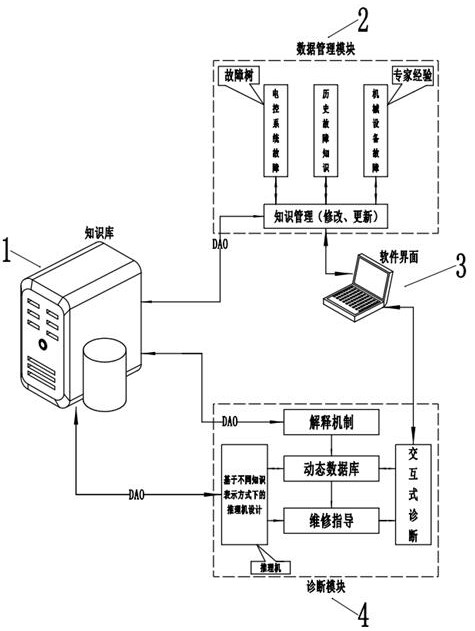

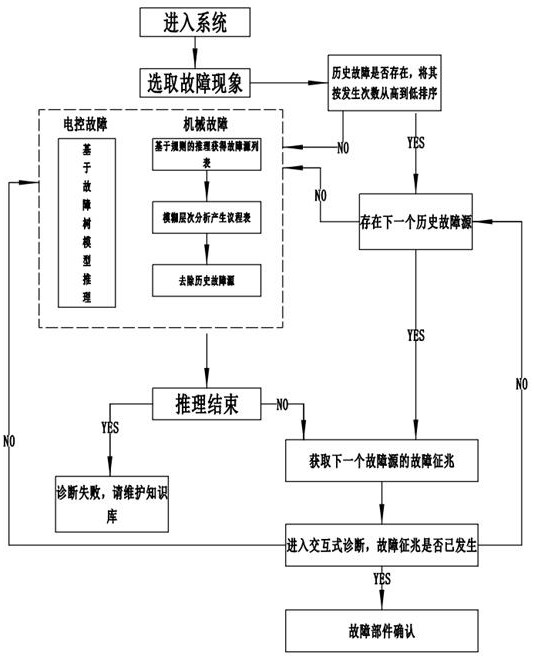

Method used

Image

Examples

Embodiment 1

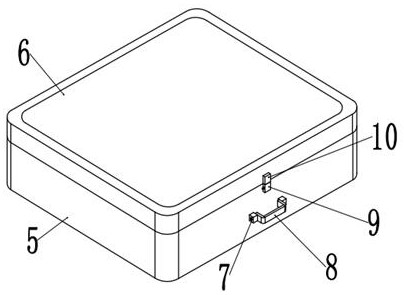

[0056] A fault location system for electromechanical equipment provided by the present invention includes a knowledge base 1 and a box body 5. One side of the top outer wall of the box body 5 is movably connected with a box cover 6 through a hinge, and one side of the box body 5 is installed with a screw through a screw. Detecting microcomputer 12, box body 5 is provided with a plurality of receiving grooves 16 near the side of testing microcomputer 12, and on the outer wall of box cover 6 close to the side of box body 5, rubber convex pad 11 fit inside box body 5 is bonded, box The center of the front outer wall of the body 5 and the case cover 6 is respectively welded with a lower positioning plate 9 and an upper positioning plate 10, and the center of the outer wall of the lower positioning plate 9 is provided with a slot 17, and the center of the inner wall on one side of the slot 17 is welded. There is a cylinder 20, and a tie rod 23 runs through the axis of the cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com