An aerodynamic design method for multi-stage axial flow compressors based on key dimensionless load control parameters

An axial flow compressor, dimensionless parameter technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as load matching imbalance, improve aerodynamic performance, improve aerodynamic design accuracy, and realize parametric optimization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in more detail below in conjunction with accompanying drawing example:

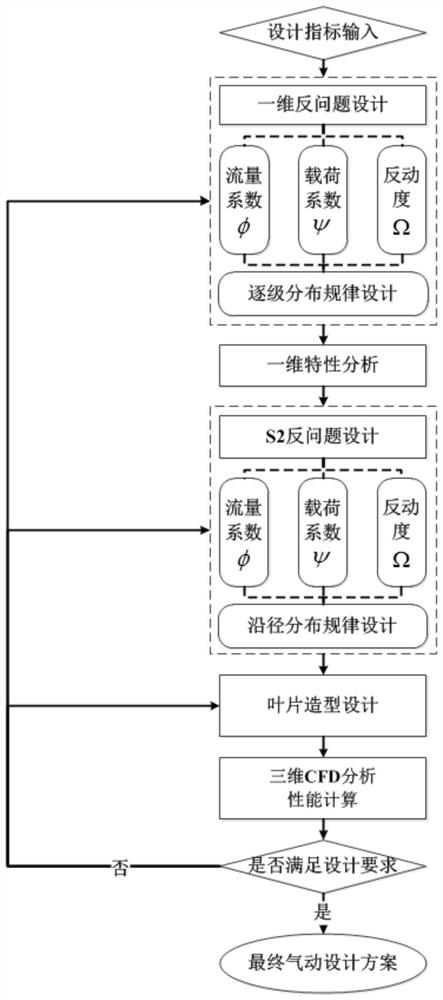

[0030] combine figure 1 , a specific implementation of an aerodynamic design method for a multi-stage axial flow compressor based on key dimensionless load control parameters is achieved through the following steps:

[0031] Step 1: One-dimensional inverse problem design. Using the three dimensionless parameters of flow coefficient φ, load coefficient ψ and reaction degree Ω as the load control parameters, the inverse problem design of the one-dimensional mean diameter of the multistage axial flow compressor is carried out, and the above three dimensionless load control parameters are completed along the Design of step-by-step distribution law of compressor flow direction.

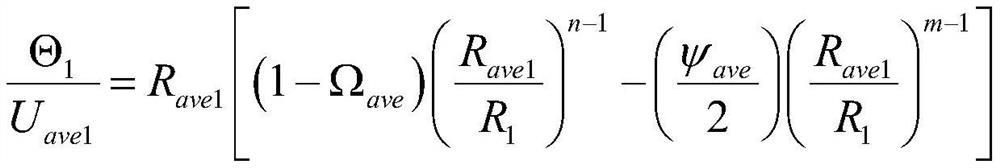

[0032] The flow coefficient φ, the load coefficient ψ and the reaction degree Ω pass through the rotor blade inlet axial velocity C 1a , the circumferential speed U of the moving blade, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com