Anti-scratch high-strength aluminum alloy cable bridge connecting device

A technology for cable bridges and connecting devices, which is applied in the direction of electrical components, etc., and can solve problems such as cable sheath scratches, cable scratches, and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

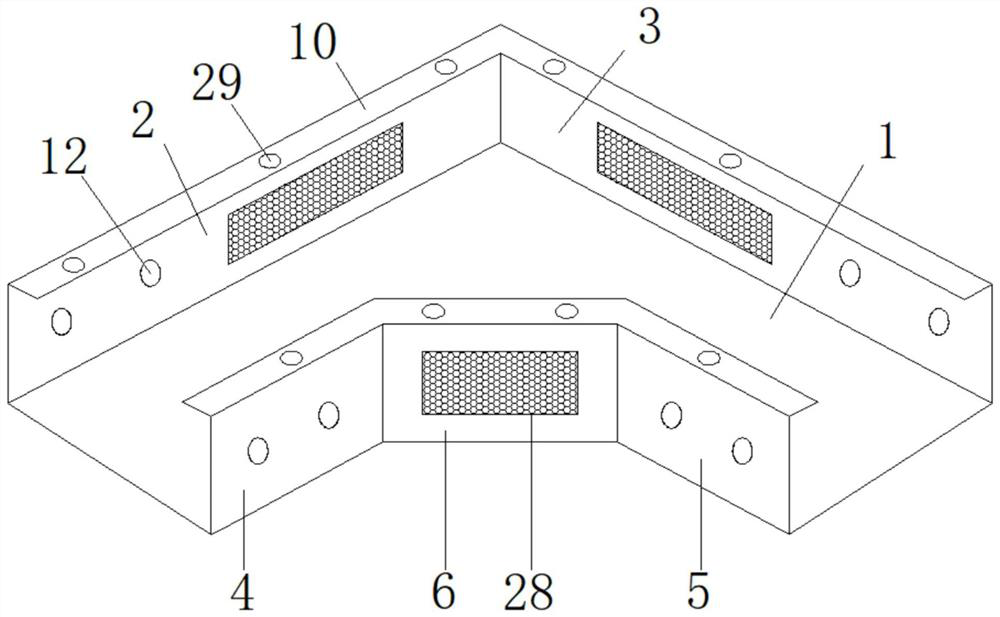

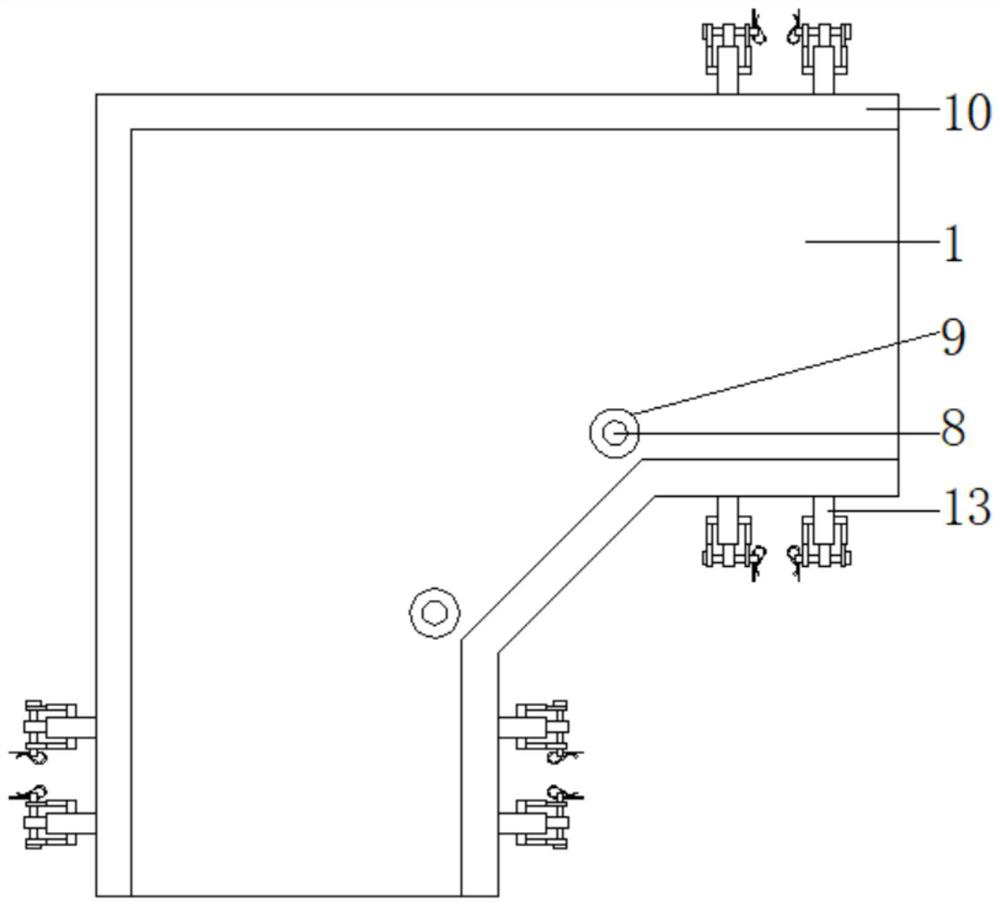

[0031] see Figure 1-9 According to an embodiment of the present invention, an anti-scratch high-strength aluminum alloy cable tray connection device includes a bottom plate 1, a first side plate 2 and a second side plate 3 are fixed on the outer side of the bottom plate 1, and the first side plate 2 is fixed on the outer side of the bottom plate 1. One side plate 2 is vertically arranged with the second side plate 3, and a third side plate 4 and a fourth side plate 5 are fixed on the inner side of the bottom plate 1, and the third side plate 4 and the fourth side plate A fifth side plate 6 is fixed between the 5, and the fifth side plate 6 is fixed on the inner side of the bottom plate 1, and two bearings 7 are fixedly embedded on the bottom plate 1, and the bearings 7 are arranged on the inner side of the intersection of the third side plate 4, the fourth side plate 5 and the fifth side plate 6 respectively, and a rotating shaft 8 is fixed inside the bearing 7, and the outer...

Embodiment 2

[0034] see Figure 1-2 , for the third side plate 4, the fourth side plate 5 and the fifth side plate 6, the angle between the third side plate 4, the fourth side plate 5 and the fifth side plate 6 are all 135°; for the first side plate, the second side plate and the fifth side plate 6, the middle parts of the first side plate 2, the second side plate 3 and the fifth side plate 6 are all opened There are heat dissipation windows 28, and dustproof nets are fixedly installed in the heat dissipation windows 28.

[0035] Through the above solution of the present invention, the heat dissipation window 28 can effectively increase the heat dissipation performance of the cable in the connection device, and the dust-proof net can prevent dust from entering the connection device, thereby preventing dust from falling on the cable surface and affecting the normal heat dissipation of the cable.

Embodiment 3

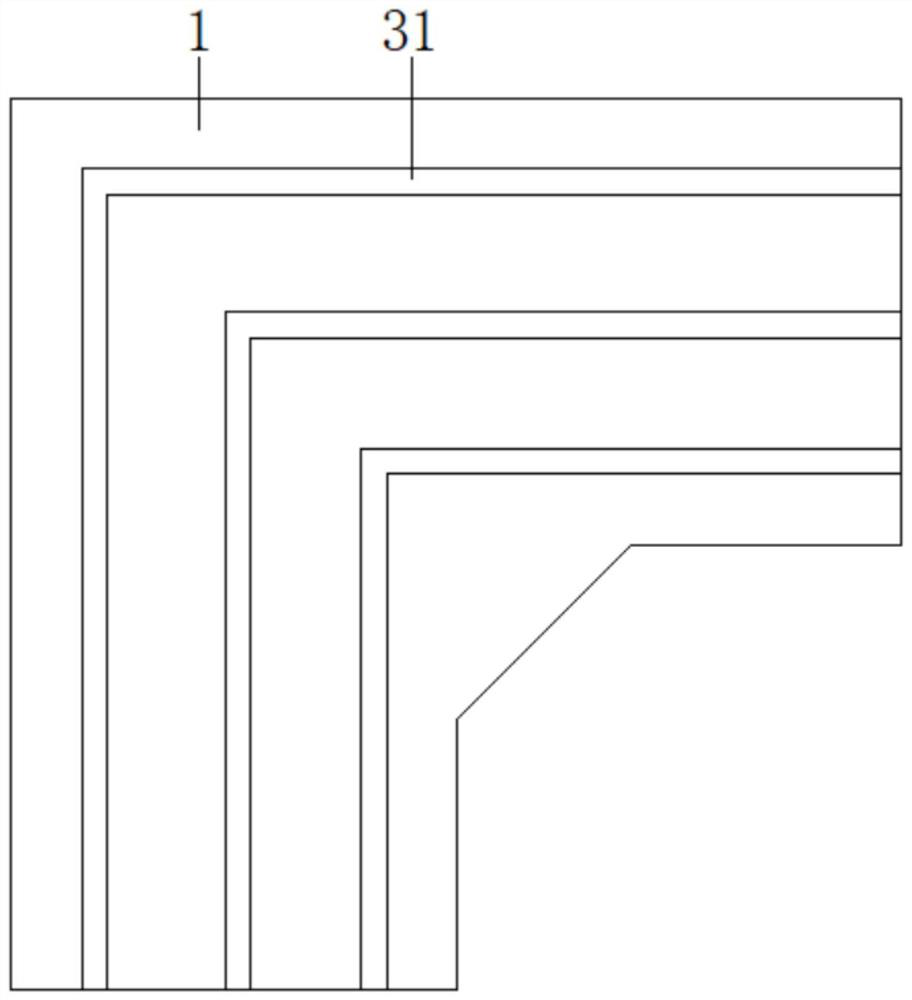

[0037] see figure 1 , 3 and 4, for the curling 10, the curling 10 is fixedly embedded with a plurality of first magnets 29, and the dust cover 11 is fixedly embedded with a plurality of second magnets 30 matching the first magnets 29 ; For the bottom plate 1, the first side plate 2, the second side plate 3, the third side plate 4, the fourth side plate 5, the fifth side plate 6, the bottom plate 1, the first side plate 2, The second side plate 3 , the third side plate 4 , the fourth side plate 5 , the fifth side plate 6 and the curling 10 are all made of aluminum alloy material and have an integrated structure; As for the base plate 1 , several reinforcing ribs 31 are fixedly arranged under the base plate 1 .

[0038] Through the above scheme of the present invention, the first magnet 29 and the second magnet 30 can effectively absorb and fix the dust cover 11, and can facilitate the disassembly of the dust cover 11. The aluminum alloy has high mechanical strength, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com