High-precision spline main shaft power head supported by sleeve

A power head, high-precision technology, applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the difficult to achieve position and speed control, difficult to meet the needs of processing, loss of spindle feed accuracy, etc. problems, to achieve the effect of reducing the influence of inertia, eliminating the need for water pipes, and the structure is beautiful and simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

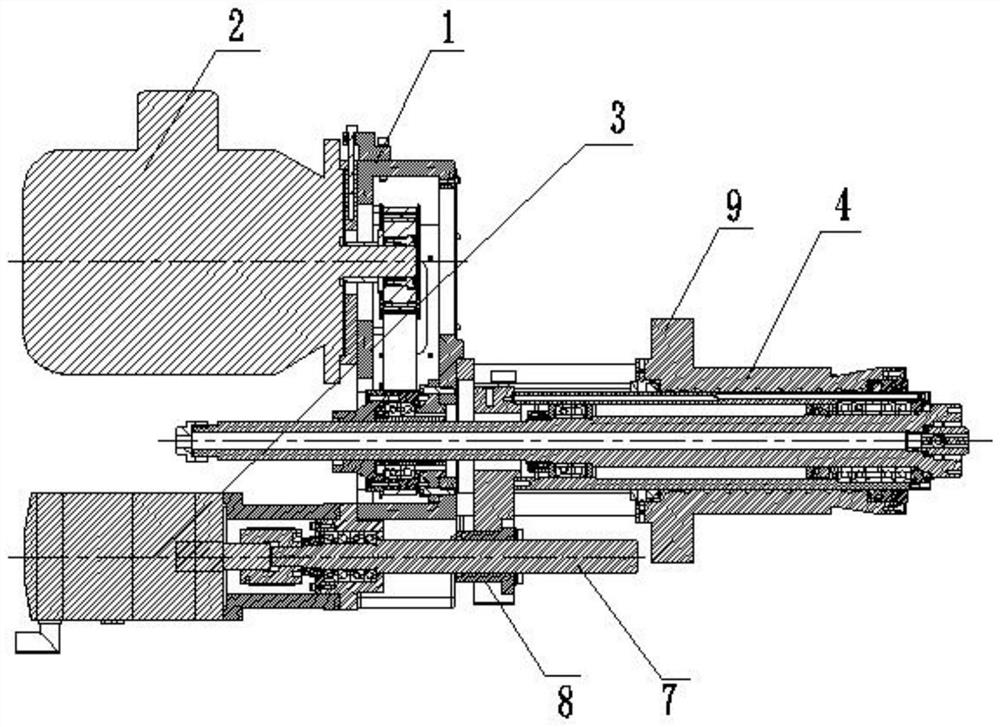

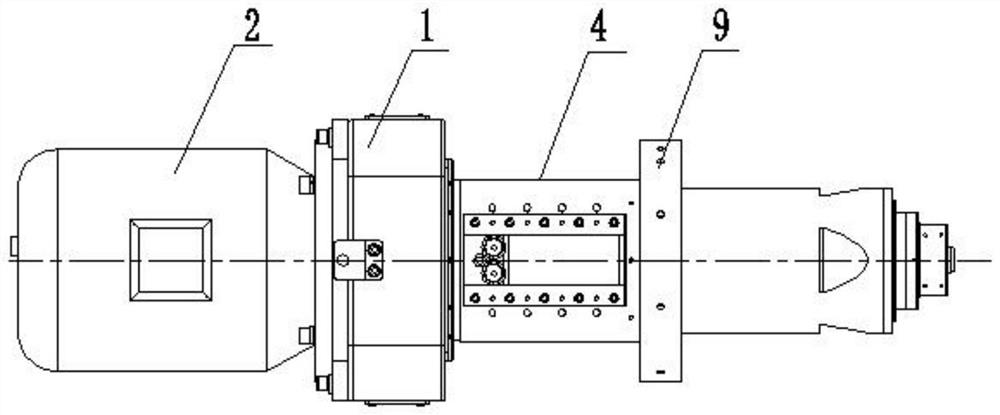

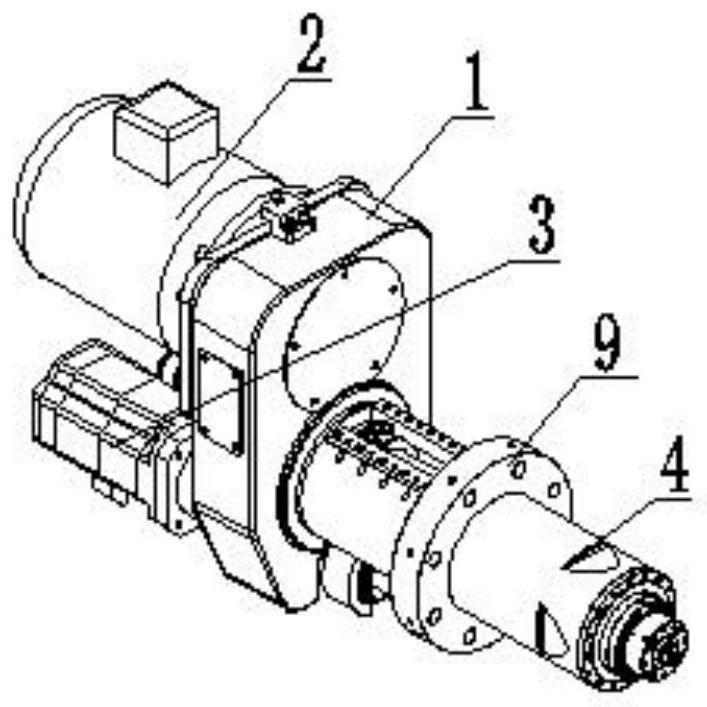

[0018] refer to Figure 1-3 , a high-precision spline spindle power head supported by a sleeve, including a connecting box 1, a three-phase asynchronous motor 2, a servo motor 3 and a power head 4 are installed on the connecting box 1, and the output shaft of the servo motor 3 passes through the connecting box. The shaft device is fixedly installed with a lead screw 7, the threaded mounting rod lead screw nut 8 on the lead screw 7, a sleeve is fixedly sleeved on the lead screw nut 8, a spline main shaft is movable installed in the power head 4, and a fixed sleeve is fixed on the power head 4 Connected with the body flange 9, the body flange 9 is fixedly installed on one side of the connection box 1, and the servo motor 3 is connected to the lead screw 7 to control the feed of the main shaft, and the accuracy and speed are much higher than traditional mechanical gears Or pneumatic feeding method.

[0019] In the present invention, the body flange 9 is provided with a spiral oi...

Embodiment 2

[0022] refer to Figure 1-3 , a high-precision spline spindle power head supported by a sleeve, including a connecting box 1, a three-phase asynchronous motor 2, a servo motor 3 and a power head 4 are installed on the connecting box 1, and the output shaft of the servo motor 3 passes through the connecting box. The shaft device is fixedly installed with a lead screw 7, the lead screw 7 is threaded to install the rod lead screw nut 8, the lead screw nut 8 is fixedly sleeved with a sleeve through welding, the power head 4 is movablely installed with a spline main shaft, and the power head 4 is The main body flange 9 is fixedly sleeved by welding, and the main body flange 9 is fixedly installed on one side of the connection box 1 by welding, and the servo motor 3 is connected to the lead screw 7 to control the feed of the main shaft, and the accuracy and speed are far away. Much higher than the traditional mechanical gear or pneumatic feed.

[0023] In the present invention, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com