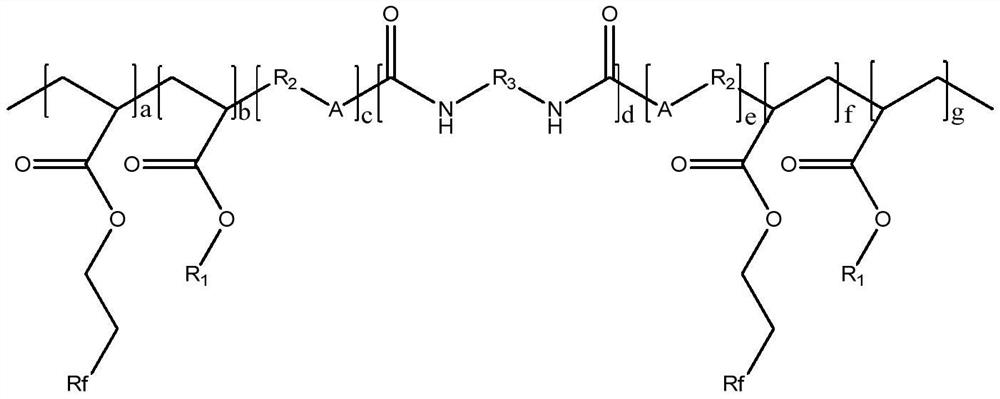

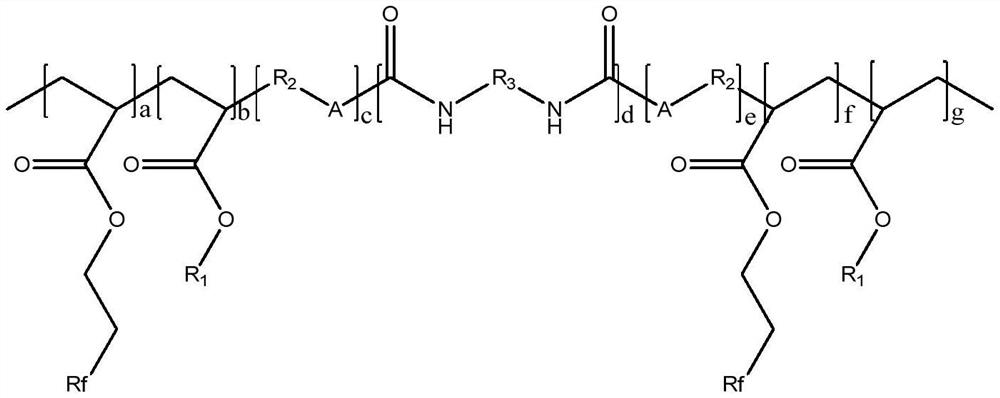

A kind of fluorine-containing graft copolymer and its preparation method and application

A technology of graft copolymer and fluorine-containing solvent, which is applied in the field of fluorine-containing graft copolymer and its preparation, can solve the problem of further improvement of waterproofing, achieve excellent acid and alkali corrosion resistance, simple method, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

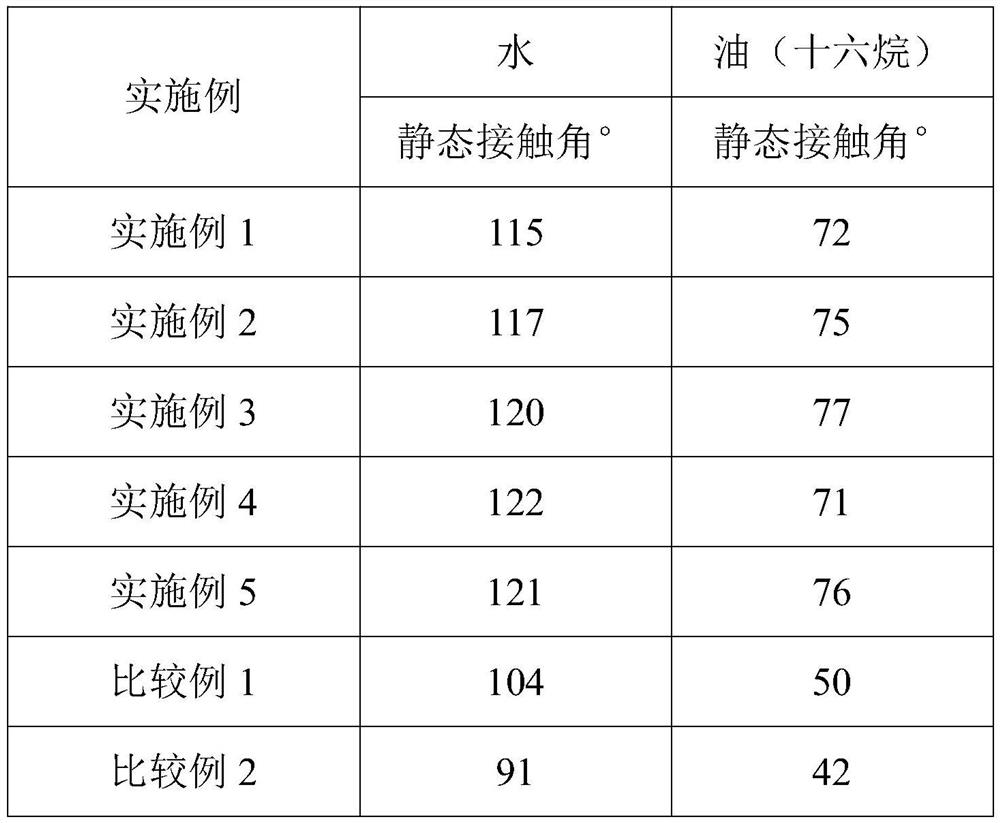

Embodiment 1

[0037] Weigh 24 g of perfluorohexyl ethyl methacrylate, 16 g of octadecyl acrylate, 2 g of 3-chloro-2-hydroxypropyl methacrylate, 1 g of tert-butyl peroxy tert-valerate and 60 g of hydrofluoroether in four In the mouth bottle, react at 75°C for 8h in a nitrogen environment, then add 2.4g of isophorone diisocyanate and 20g of hydrofluoroether to the reaction flask, turn off the nitrogen, react at 75°C for 8h, and then add 9g of perfluorohexylethyl methacrylate, 6g of octadecyl acrylate, 2g of 3-chloro-2-hydroxypropyl methacrylate, 1g of tert-butyl peroxy tert-valerate and 60g of hydrofluoroether, in a nitrogen atmosphere After reacting at a temperature of 75°C for 8 hours, turn off the nitrogen gas to end the reaction to obtain a solution of the fluorine-containing copolymer.

Embodiment 2

[0039] Weigh 24g of perfluorohexylethyl methacrylate, 16g of stearyl acrylate, 2g of mercaptoethanol, 1g of tert-butyl peroxy tert-butyl valerate, and 60g of hydrofluoroether in a four-necked bottle, and place in a nitrogen atmosphere at 75°C React for 8 hours, then add 2.4 g of isophorone diisocyanate and 20 g of hydrofluoroether to the reaction bottle, turn off the nitrogen, react at 75°C for 8 hours, then add 9 g of perfluorohexylethyl methacrylate into the reaction bottle , 6 g of stearyl acrylate, 2 g of hydrofluoroether, 1 g of tert-butyl peroxyvaleric acid and 60 g of hydrofluoroether, reacted at 75 °C for 8 hours in a nitrogen environment, and then closed the nitrogen to complete the reaction to obtain a solution of fluorine-containing copolymer .

Embodiment 3

[0041] Weigh 24 g of perfluorohexyl ethyl methacrylate, 16 g of octadecyl acrylate, 2 g of 3-chloro-2-hydroxypropyl methacrylate, 1 g of tert-butyl peroxy tert-valerate and 60 g of hydrofluoroether in four In the mouth bottle, react at 75°C for 8h in a nitrogen environment, then add 2.4g of isophorone diisocyanate and 20g of hydrofluoroether to the reaction flask, turn off the nitrogen, react at 75°C for 8h, and then add 9g of perfluorohexylethyl methacrylate, 6g of octadecyl acrylate, 2g of 3-chloro-2-hydroxypropyl methacrylate, 1g of tert-butyl peroxy tert-valerate and 60g of hydrofluoroether, in nitrogen atmosphere After reacting at 75°C for 8 hours in the environment, turn off the nitrogen gas to end the reaction to obtain a solution of the fluorine-containing copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com