Granite road edge stone paving vehicle and paving method thereof

A technology of granite and curbstones, which is applied in the field of municipal engineering road construction equipment and construction, can solve the time-consuming and labor-intensive task of manually completing curbstone masonry, the inability to adjust the direction and angle of curbstones, and the inconvenience of lifting curbstones and other issues, to achieve the effects of optimizing and adjusting control methods, improving transportation efficiency and safety, and good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment provides a vehicle for paving granite curbs.

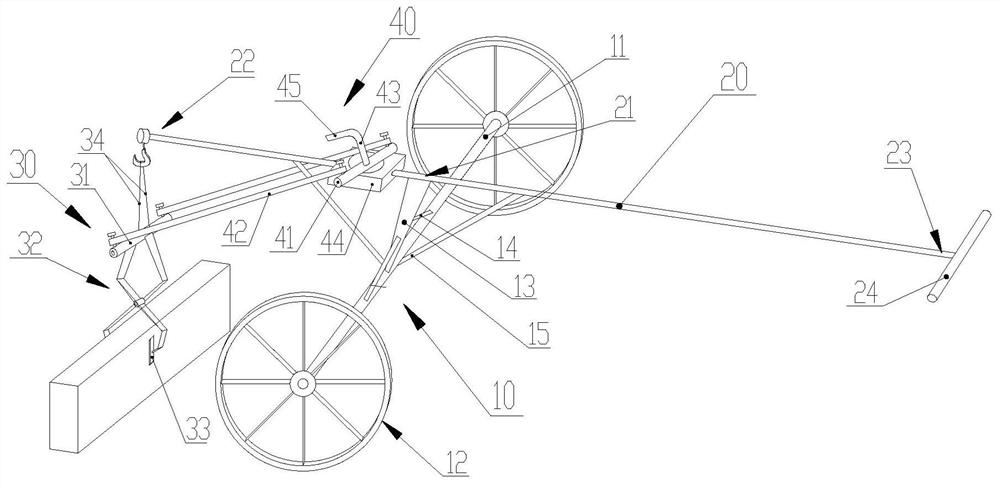

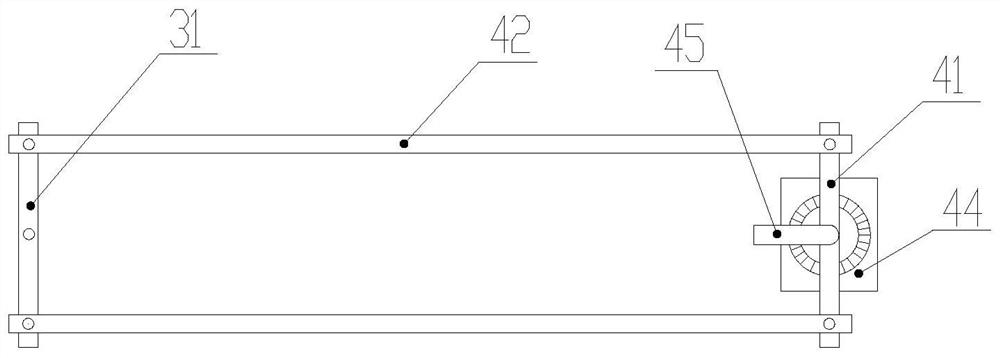

[0070] Such as figure 1 A schematic diagram of a three-dimensional structure of a vehicle for paving granite roadside stones provided by an embodiment of the present invention, figure 2 A structural schematic diagram of a positioner in a vehicle for paving granite roadside stones provided by an embodiment of the present invention is as follows:

[0071] A vehicle for laying granite roadside stones, comprising:

[0072] Parallel two-wheeled vehicle 10, lever 20, slate clamp 30 and locator 40;

[0073] Parallel two-wheeled vehicle 10 comprises axle shaft 11 and wheel 12, and wheel 12 is rotatably connected to the two ends of axle shaft 11;

[0074] The lever 20 is fixed on the axle 11 and arranged at right angles to the axle 11, the connection point between the lever 20 and the axle 11 is the fulcrum 21 of the lever 20, one end of the lever 20 is the lifting end 22, and the other end of the lever 20 is the...

Embodiment 2

[0088] This embodiment provides a paving method for granite curbstones.

[0089] The pavement method of the granite curb stone provided in this embodiment includes:

[0090] The steps of measurement and setting out, nail pile wiring, mortar cushion, granite road curb transportation, pavement and masonry, as well as the steps of filling and compacting the bottom of granite road curb and joint maintenance, wherein:

[0091] The step of transporting and paving the granite curb is assisted by the vehicle for paving the granite curb provided in the first embodiment, and the rest of the steps are completed according to the prior art.

[0092] The transportation, paving and laying of granite roadside stones are assisted by the granite roadside stone paving vehicle, which specifically includes the following steps:

[0093] Adjust the control rod so that the direction rod and the lever are distributed at right angles;

[0094] Push the vehicle for paving the granite curb to the stora...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap