Pipeline connection joint applied to on-site maintenance

A technology for pipeline connection and on-site maintenance, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve problems such as inconvenient maintenance of rubber pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

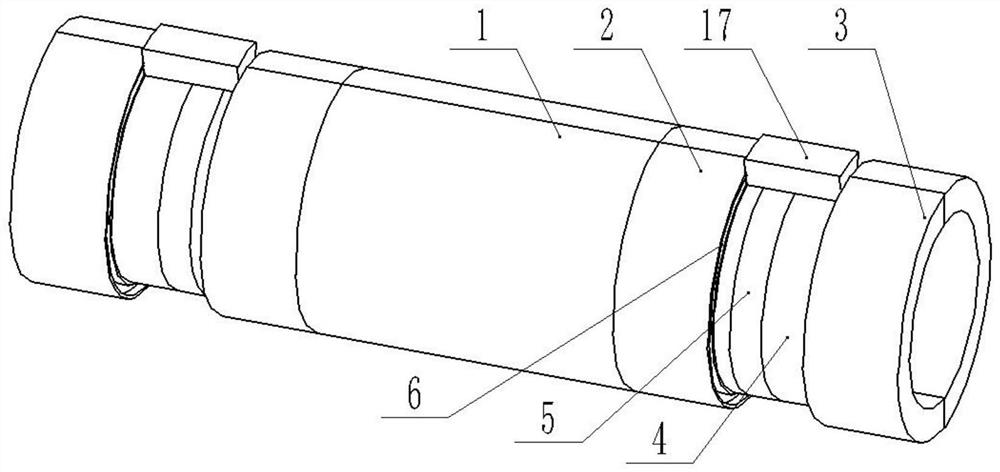

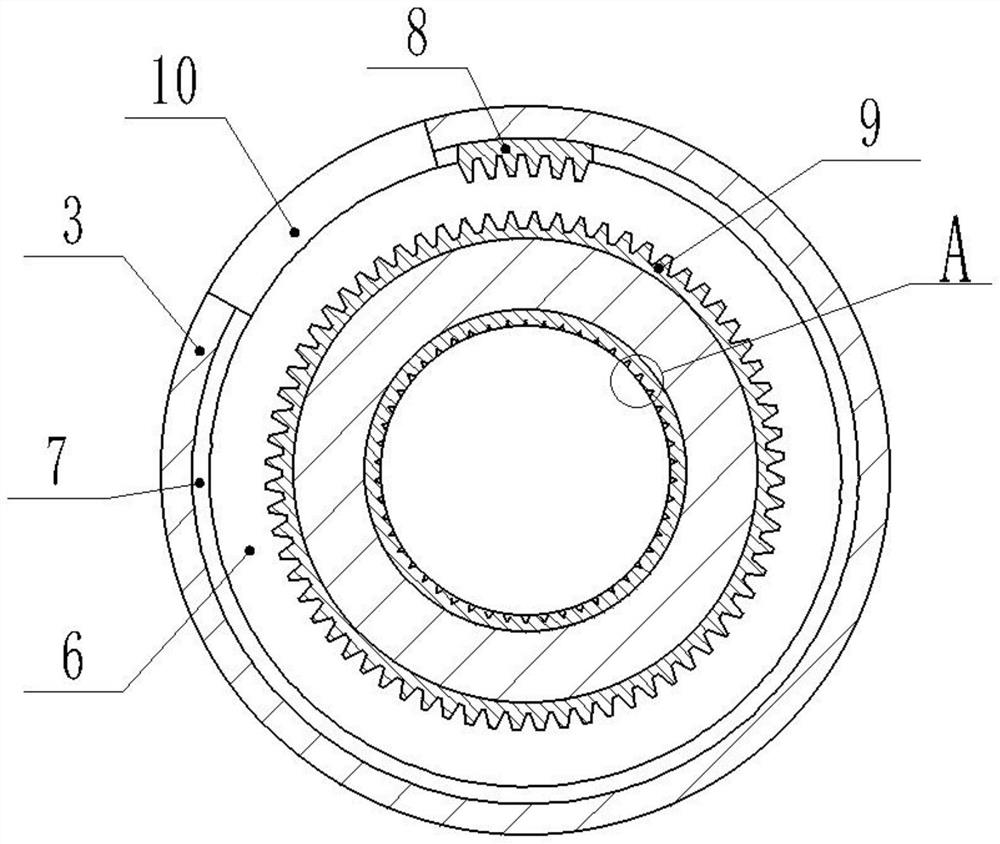

[0033] A field serviceable line connection fitting such as Figure 1-Figure 9 As shown, it includes a connecting cylinder 1 and welding cylinders arranged at both ends of the connecting cylinder 1 .

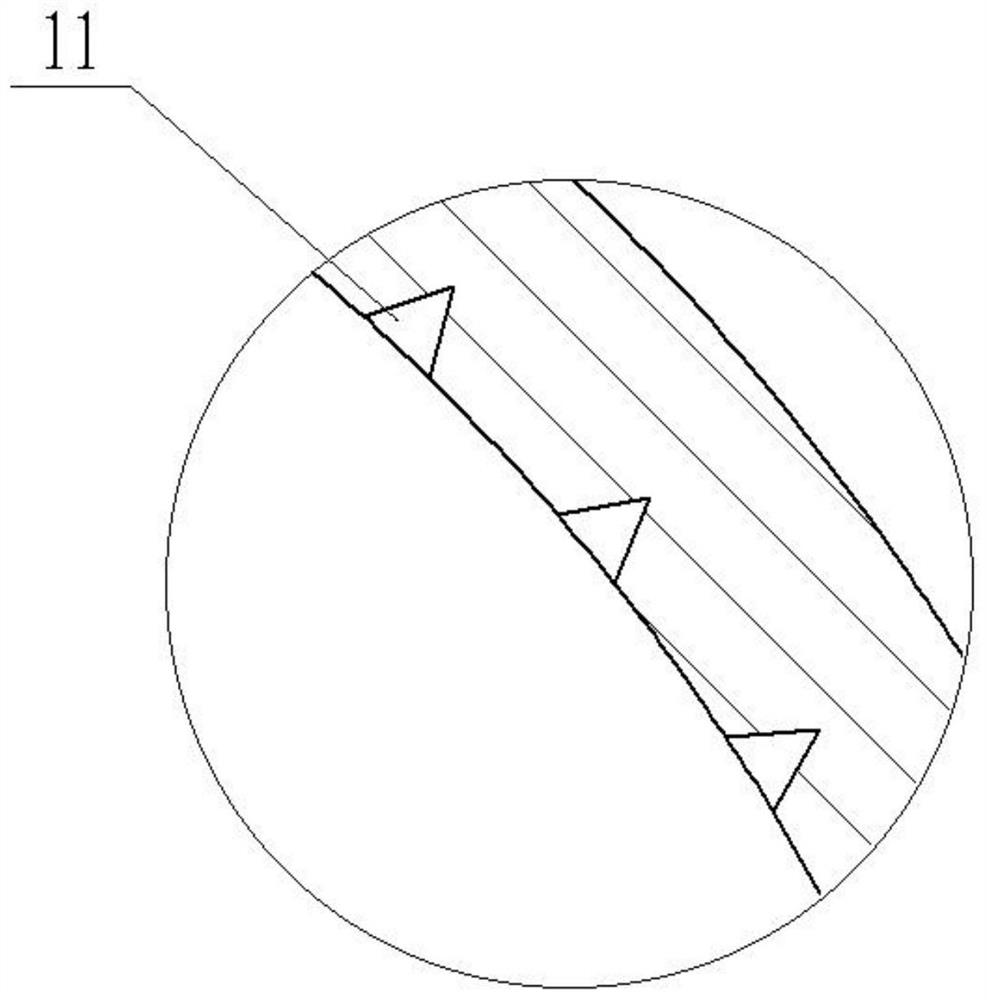

[0034] The fusion barrel includes a first side pipe 3 and a second side pipe 2 , and the second side pipe 2 is fixedly connected with the connection barrel 1 . The first side pipe 3, the second side pipe 2 and the connecting cylinder 1 are all composed of two half-rings, that is, the three can be disassembled into two half-rings, and can be combined into a whole ring by bolts. A welding ring 4 is fixedly arranged between the first side pipe 3 and the second side pipe 2 , and a vacuum groove 19 is provided on a part of the inner wall of the welding ring 4 close to the first side pipe 3 . The vacuum groove 19 is annular and concentric with the second welding ring 4. The vacuum groove 19 is sealed with an annular plastic strip 18. The melting temperature of the plastic strip 18 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com