Drying device for feed processing

A drying device and feed processing technology, which is used in drying solid materials, mixers with rotary stirring devices, drying, etc., can solve the problems of inability to process soaked feed, inability to solve waste water, etc., and achieve the effect of improving the effect and speeding up the speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

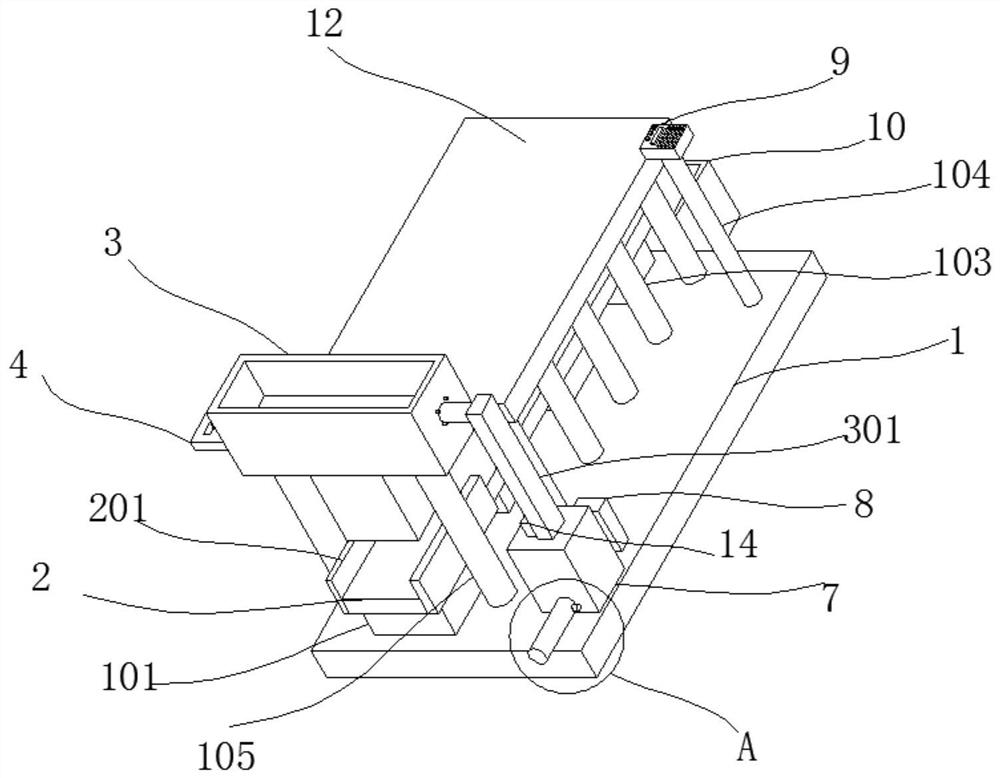

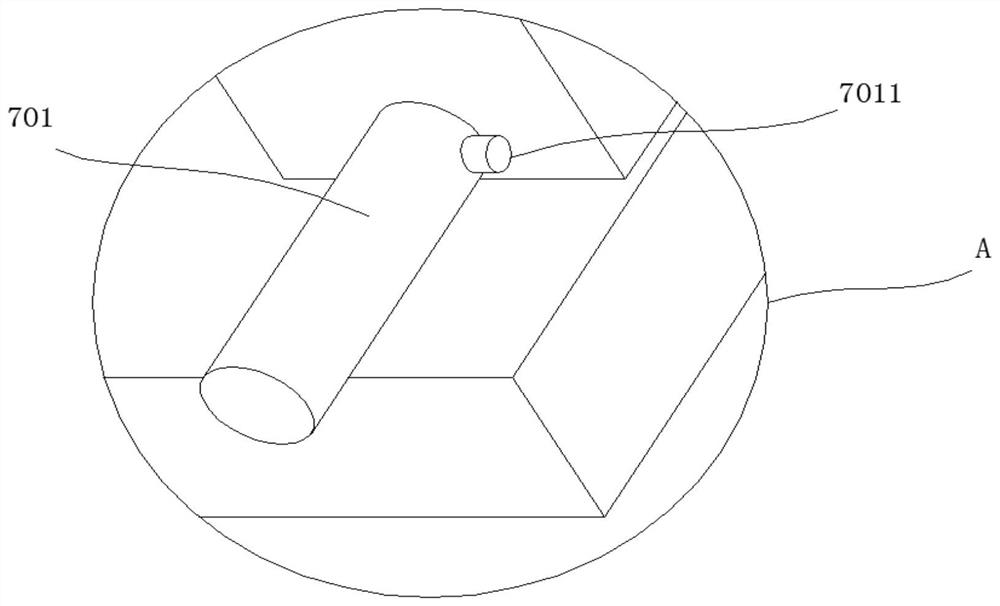

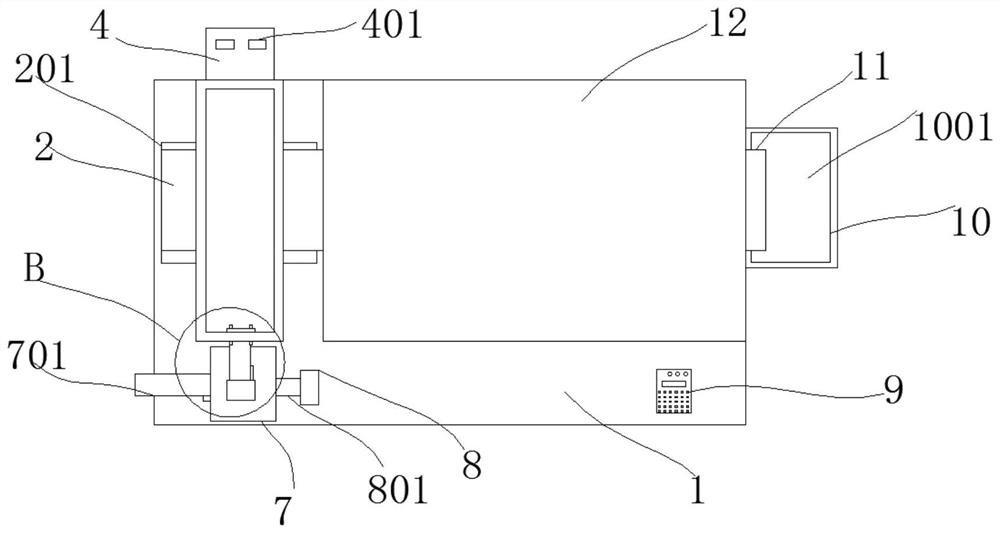

Embodiment 1

[0035] This embodiment is a method of using a drying device for feed processing: when the drying device needs to be used, pour the soaked feed into the treatment box 3, let the water flow out from the filter plate 5 and send it to the storage tank through the circulation pipe 301. In the water tank 7, pull out the baffle plate 4, let the feed fall onto the first conveyer belt 2 through the feed pipe 302, operate the control panel 9 to control the work of the first conveyer belt 2, and send the feed to the second conveyer belt 11, while controlling the second The conveyor belt 11 works to bring the feed to different positions on the second conveyor belt 11 until the feed reaches one end near the collection box 10, stop the work of the second conveyor belt 11, and stop the work of the first conveyor belt 2 at the same time to feed, operate the control panel 9, control the motor The telescopic rod 103 moves upwards or downwards, adjusted to the appropriate height required when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com