Nitrogen blowing assembly of solid-phase extraction nitrogen blowing concentrator

A concentrator and nitrogen blowing technology, applied in the field of separation, can solve the problems of waste of manpower and material resources, rough constant volume accuracy, and inability to extract samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

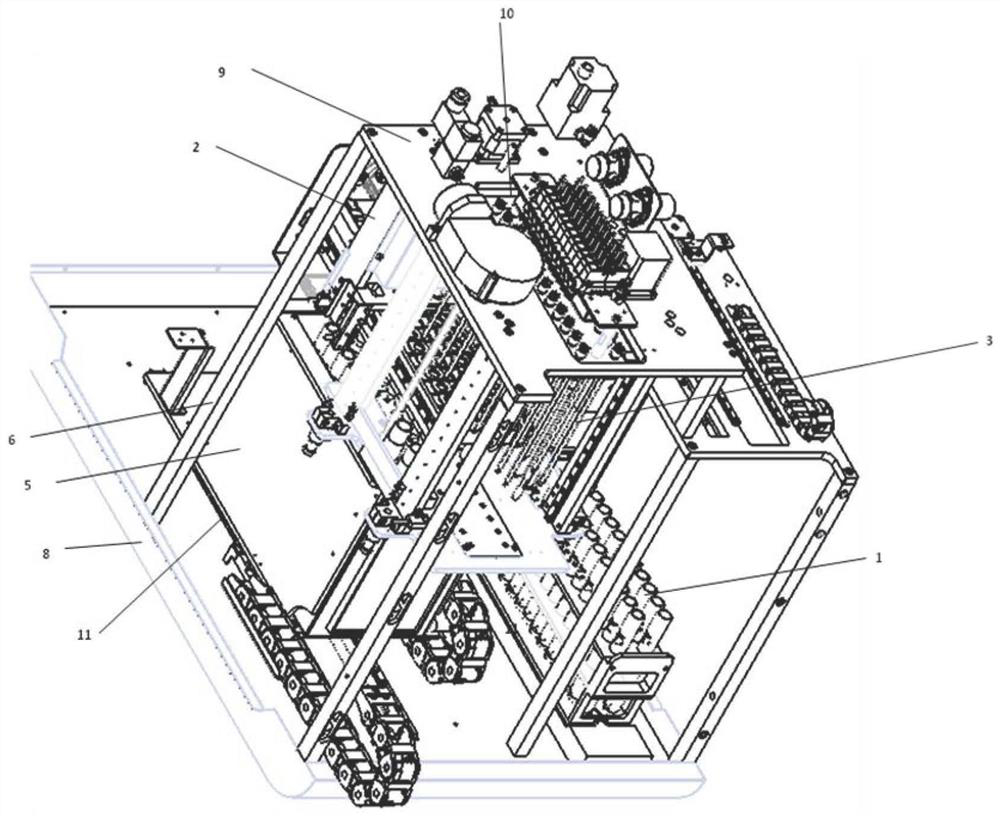

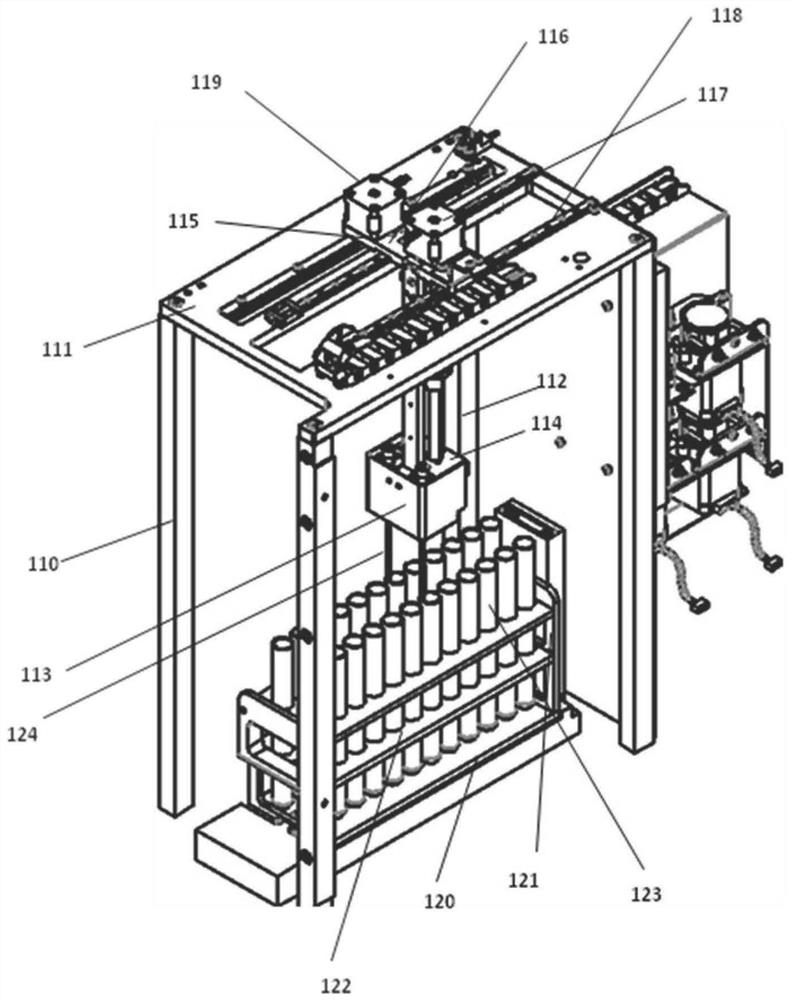

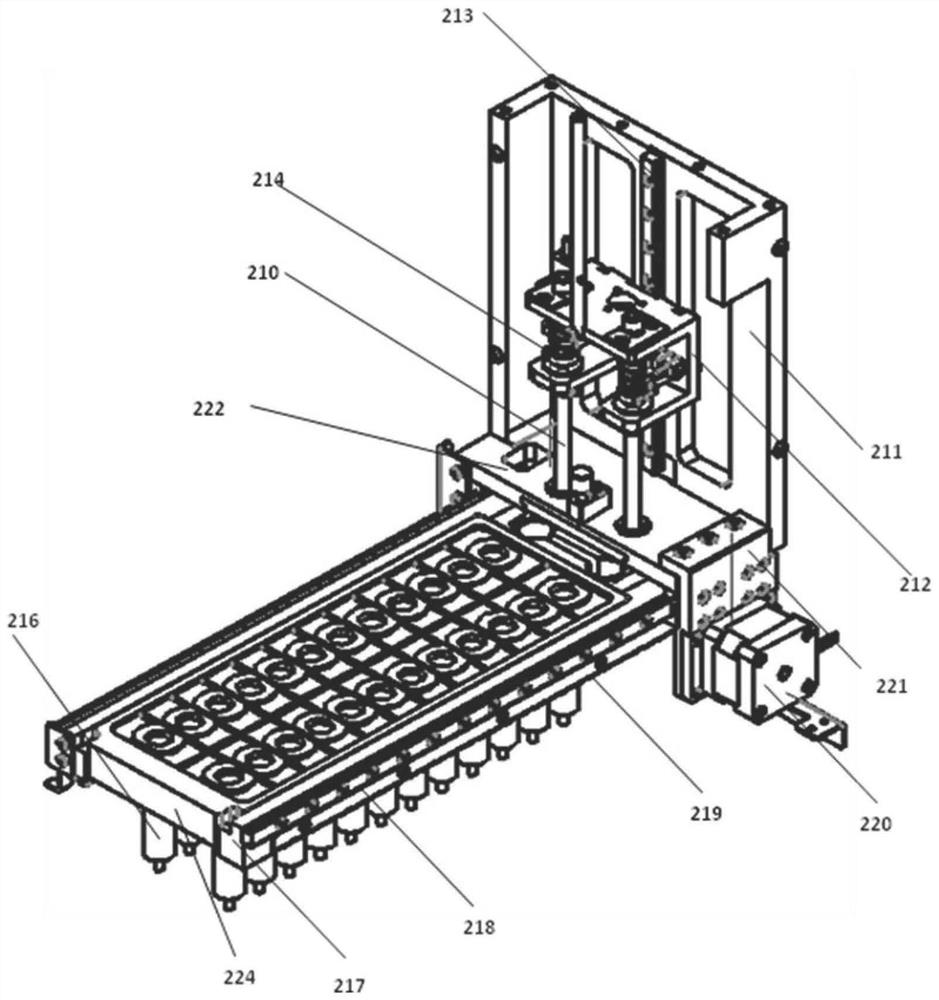

[0034] The invention relates to a nitrogen blowing component of a solid phase extraction nitrogen blowing concentrator, such as Figure 1-8As shown, it includes a bottom plate 8, a pillar 6, a base assembly 11, the base plate 8 is provided with the base assembly 11, the base assembly 11 is provided with a concentrated water tank assembly 5, and the concentrated water tank assembly 5 is provided above the Nitrogen blowing lifting assembly 3, the rear of nitrogen blowing lifting assembly 3 is provided with SPE column insert assembly 2, the right side of the nitrogen blowing lifting assembly 3 is provided with sample loading assembly 1, and the column 6 is 4, of which the left The lower ends of the two pillars 6 are vertically and fixedly connected to the bottom plate 8, and the lower ends of the two pillars 6 on the right side are fixedly connected to the upper guide rail mounting plate 111 of the sample loading needle. The sample loading assembly 1 includes the upper guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com