Defect detection device and method

A defect detection and polarization direction technology, applied in the field of optical detection, can solve problems such as false detection, increased workload, detection of areas near reflections, etc., achieve fast response speed, improve defect detection and recognition accuracy, improve defect detection and The effect of recognition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

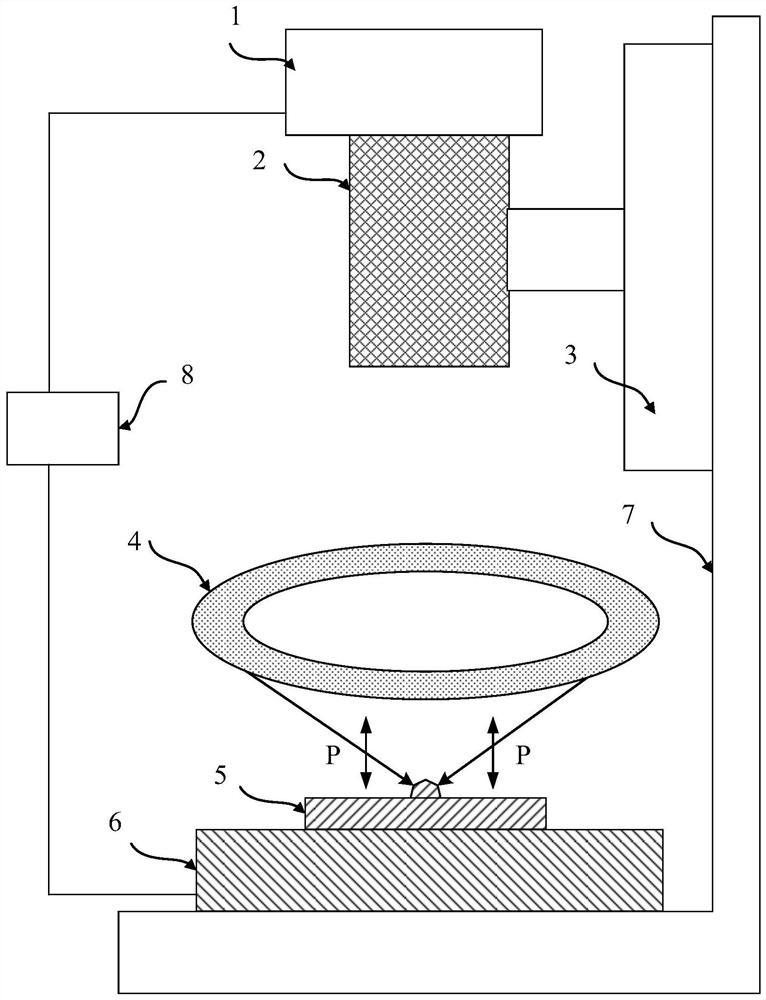

[0060]The present invention is further detailed in conjunction with the accompanying drawings and examples. It will be appreciated that the specific embodiments described herein are merely illustrative of the invention and are not limited thereto. It will also be noted that in order to facilitate the description, only the parts associated with the present invention are shown in the drawings rather than all structures.

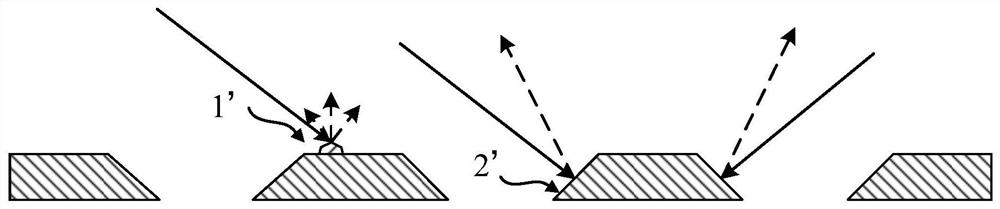

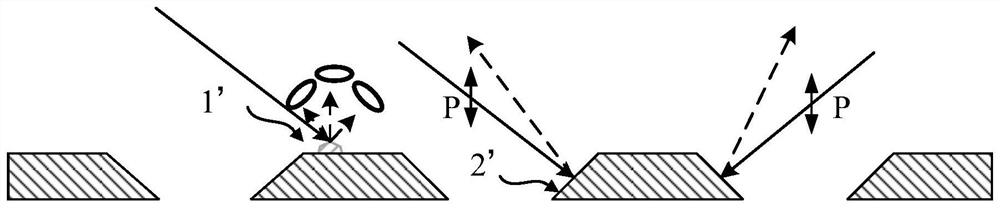

[0061]figure 1 Schematic diagram of metal film stamping angle and particle defects under dark field lighting conditions, referencefigure 1 The detection process of ordinary particle defect 1 'on the metal film is shown, wherein the metal film may, for example, a mask plate, a mask plate including a metal film stamping process, resulting in an inclined surface formed by the upper and lower surface of the metal film. The oblique shot dark field illumination beam (non-polarized light) illuminates the ordinary particle defect 1 ', and the partial light is absorbed by the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com