Equipment for cleaning dust attached to surface of rotating shaft of fan and keeping rotating speed

A technology of surface adhesion and rotating shaft, which is applied in the direction of mechanical equipment, engine lubrication, engine components, etc., can solve the problems of slowing down the fan, fan damage, temperature rise, etc., and achieve the effect of reducing motion friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

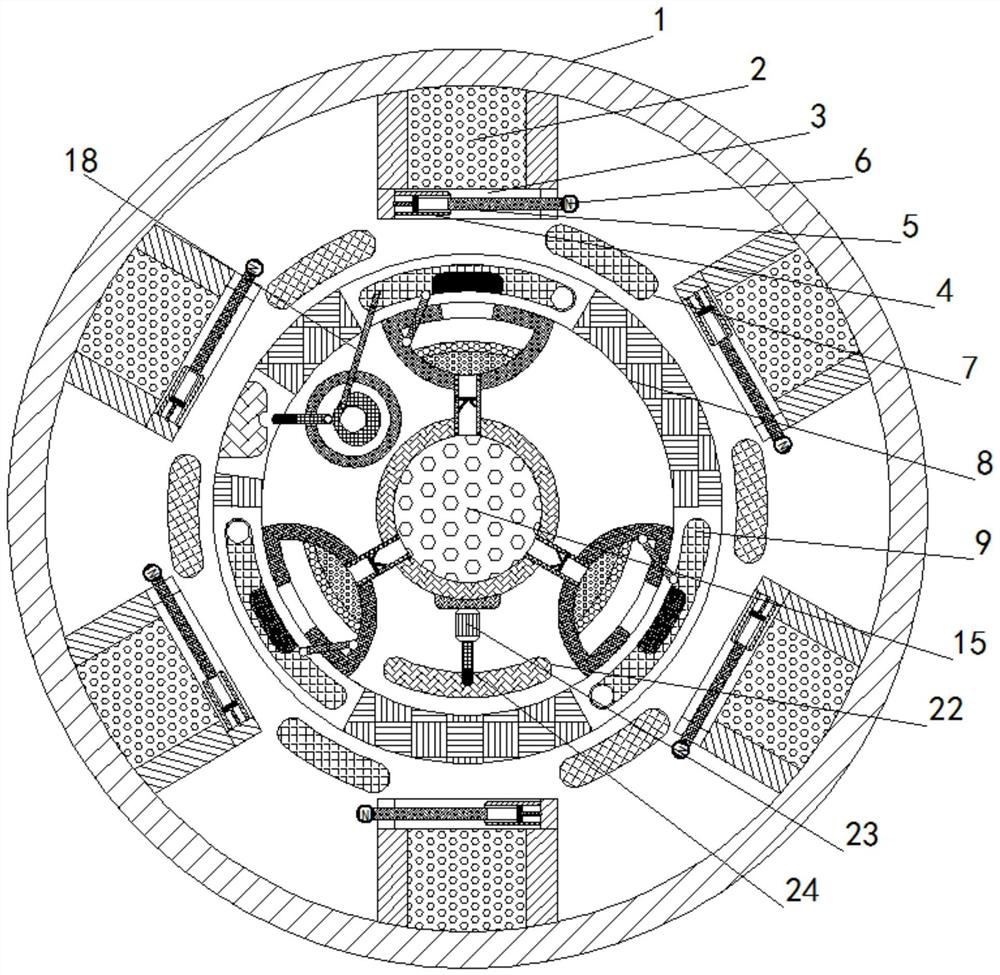

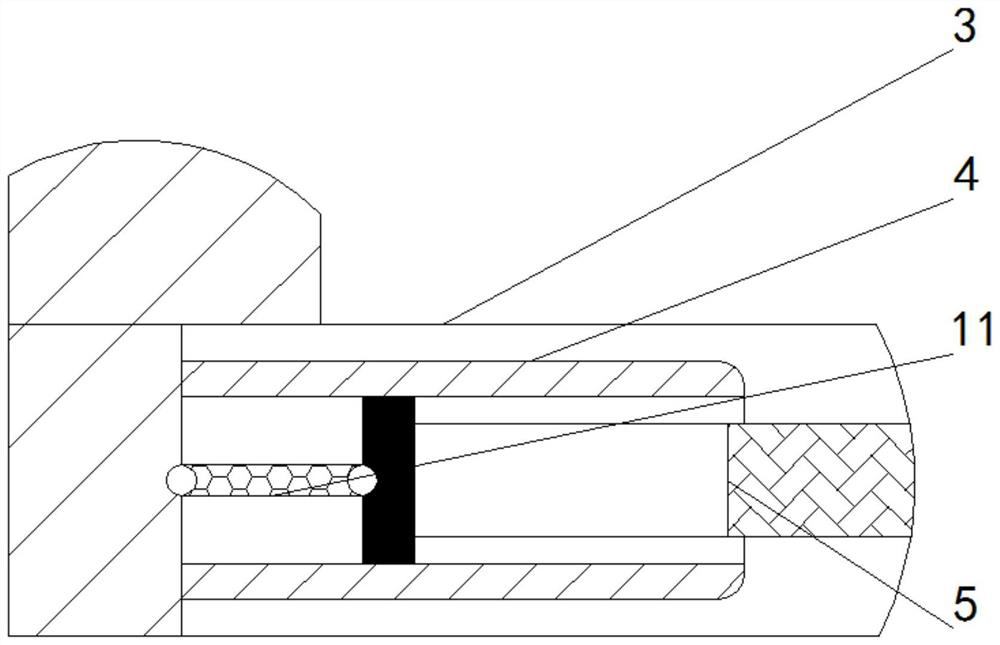

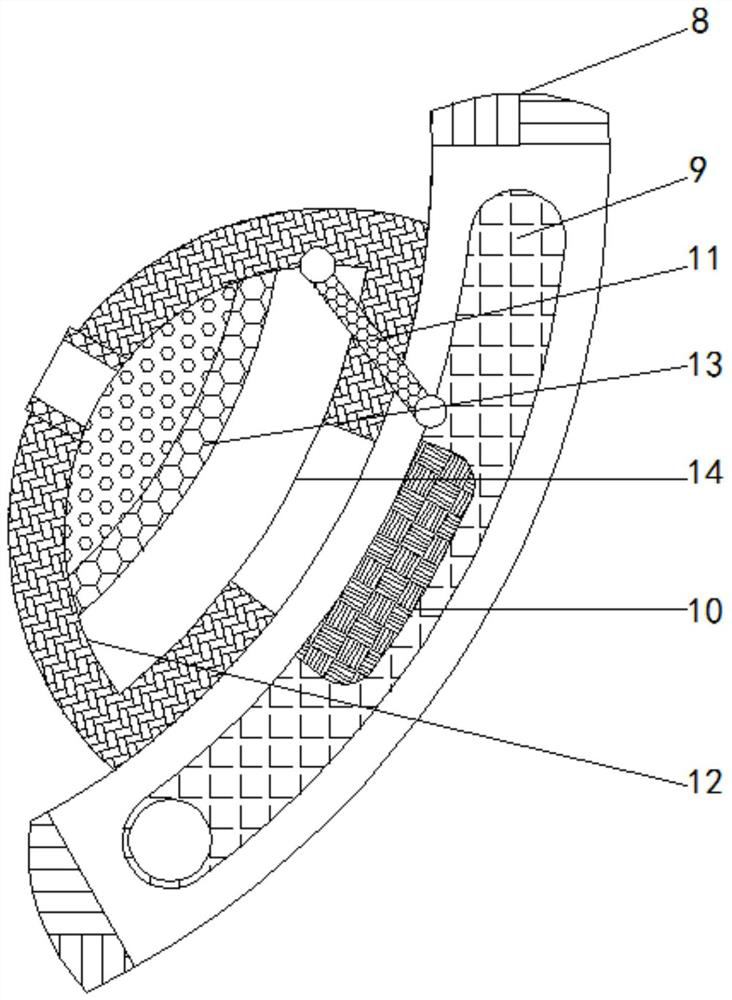

[0025]SeeFigure 1-5, A device for cleaning the fan rotating shaft surface adhesion dust retention speed, including a fixed disc 1, the inner wall of the fixed disc 1 is fixedly mounted with a water tank 2, and the inside of the water tank 2 is placed, the lubricant is a flowing solid state, There is a valve groove 3 at the bottom of the water tank 2, and the inside of the valve groove 3 is fixedly mounted, and the inside of the telescoping rod 4 is slidably connected to the valve block 5, and the valve block 5 is in the first par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com