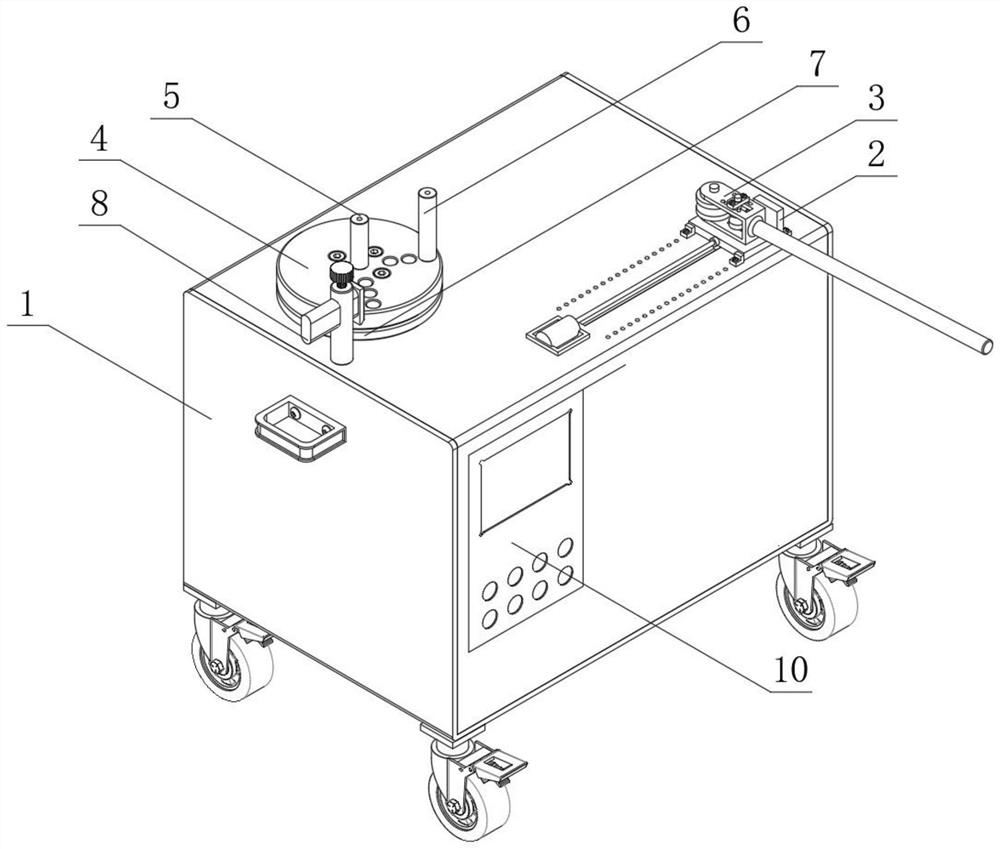

Pipe bending mechanism for hardware pipe machining and working method thereof

A technology for bending pipes and pipes, which is applied in the field of hardware pipe processing equipment, and can solve the problems of easy falling off, loose fixation, poor use safety effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

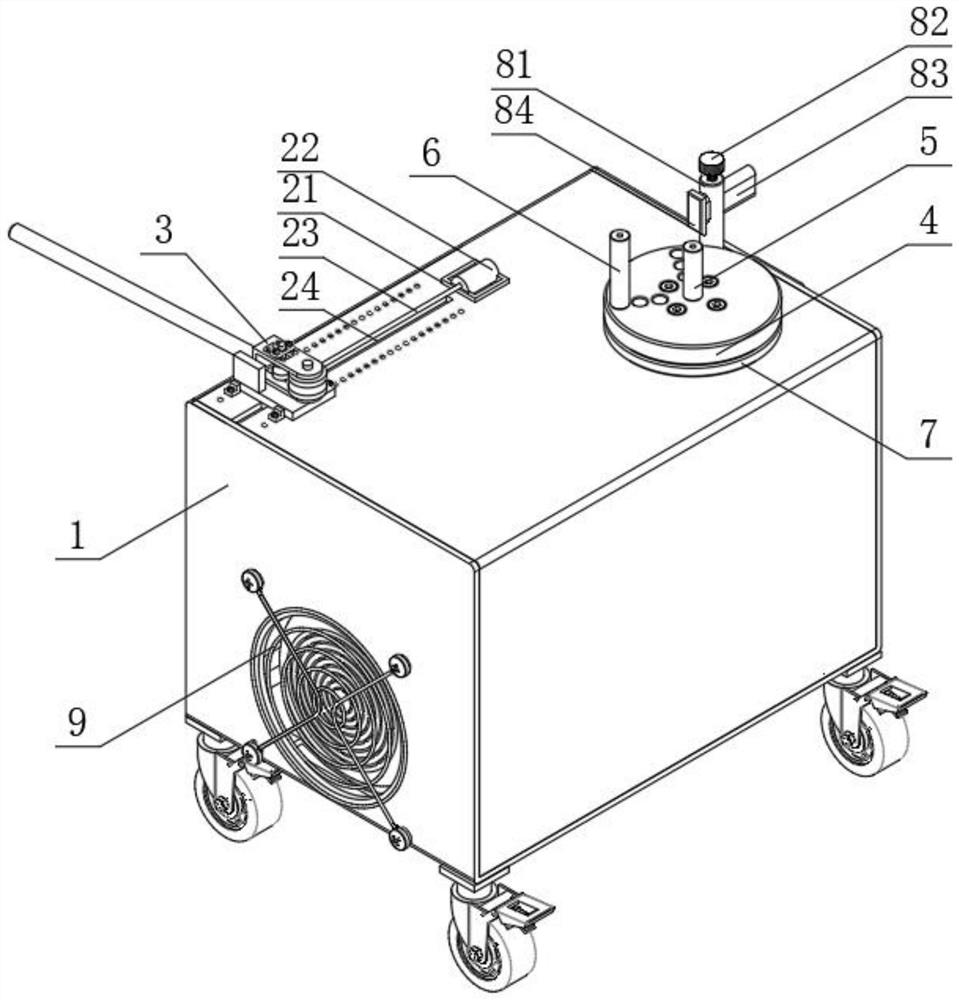

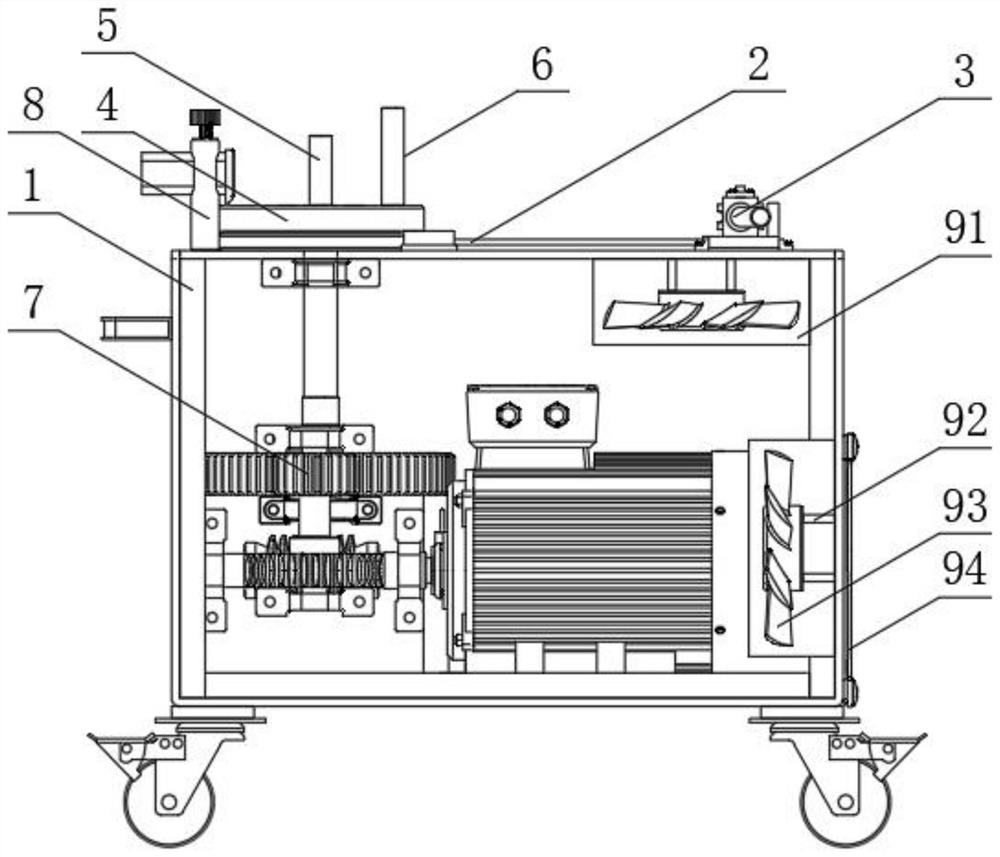

[0026]As an embodiment of the present invention, the displacement assembly 2 includes a fixing frame 21, an electric push rod 22, an extension rod 23, a guide slide 24, and a fastening seat 25, and the fastener 21 is fixedly mounted on the top end of the chassis 1. On one side, the upper surface of the fixing frame 21 is fixedly mounted with the electric push rod 22 by a screw, and one end of the electric push rod 22 is attached to the mounting rod 23, and the other end of the extension rod 23 is connected to the fastening seat 25, and the fastening seat One end of 25 is fixed to the adjustment bottom plate 39, and the guide chute 24 is opened on the top surface side of the chassis 1, and the guide slider 310 is inserted inside the guide slot 24, and it is easy to adjust the position of the adjustment the bottom plate 39, thereby Convenient for pipe for different lengths.

[0027]As an embodiment of the present invention, the upper end surface of the chassis 1 is located on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com