Clamping platform for workpiece overturning and workpiece polishing and cleaning system

A workpiece and platform technology, applied in the field of clamping platform and workpiece grinding and cleaning system, can solve the problem of workpiece transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

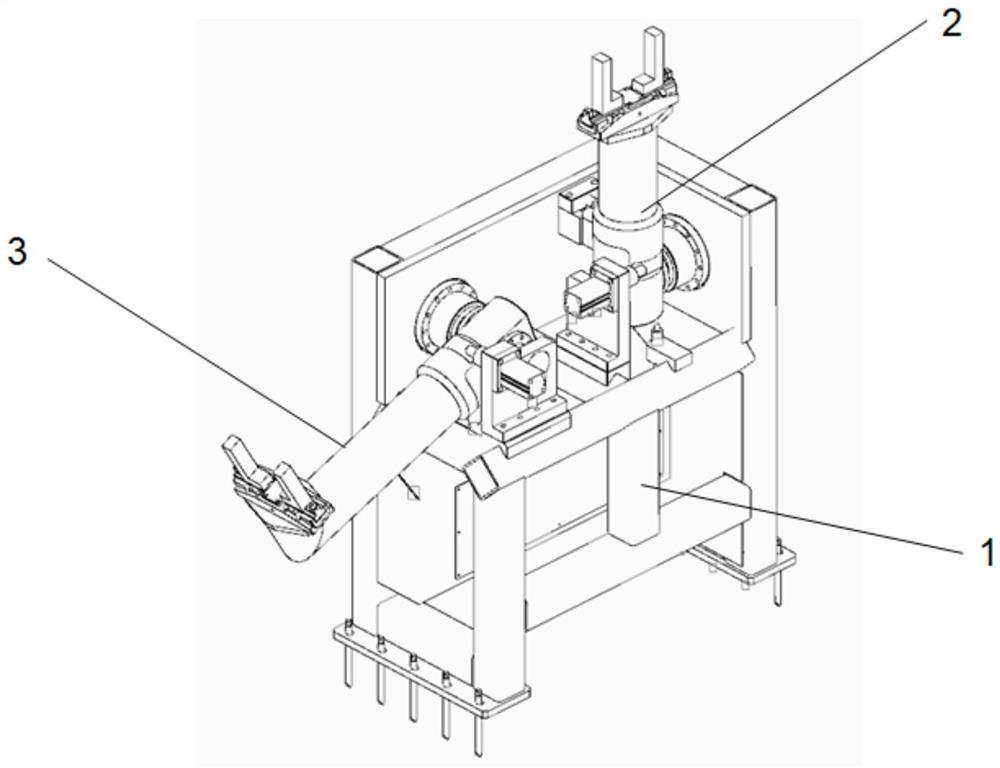

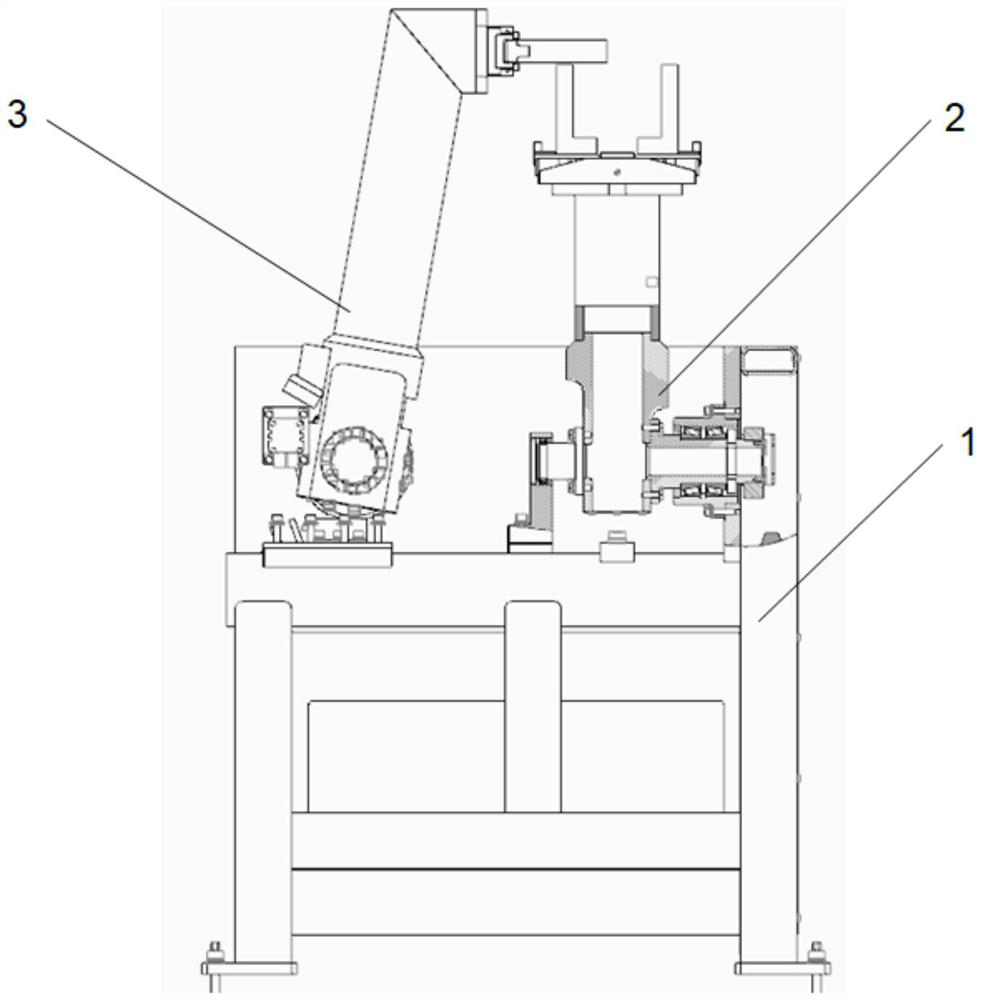

[0038] see figure 1 , figure 2 and Figure 7 , In one embodiment, a clamping platform for turning workpieces includes a frame 1 , a first clamping part 2 and a second clamping part 3 .

[0039] The frame 1 is arranged on the external platform. The first clamping part 2 and the second clamping part 3 are respectively arranged on the machine frame 1, and are respectively used for clamping and driving the workpiece to be processed to turn over. Both the clamping direction and the overturning direction of the first clamping part 2 are perpendicular to the second clamping part 3 , and the overturning track of the first clamping part 2 interferes with the overturning track of the second clamping part 3 .

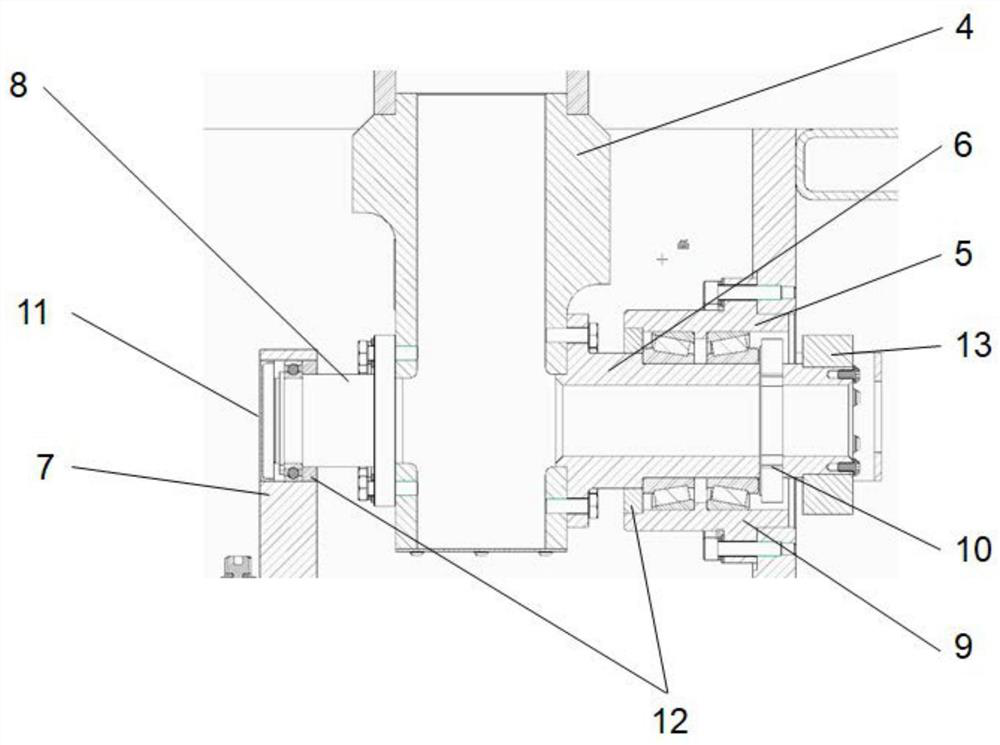

[0040] Wherein, both the first clamping part 2 and the second clamping part 3 are a clamping structure, and the clamping structure includes a rotation unit, a driving unit, an execution unit and a clamping unit. The rotating unit is arranged on the frame 1, and the output end...

Embodiment 2

[0053] A grinding and cleaning system for workpieces includes the clamping platform for turning workpieces according to the first embodiment above. The clamping platform is provided with a first clamping part 2 and a second clamping part 3 perpendicular to each other on the frame 1, and the turning tracks of the two clamping parts interfere with each other. Taking a square workpiece as an example, when cleaning, first clamp the two opposite surfaces of the workpiece to be processed by the first clamping part 2, and then turn over the first clamping part 2 to the processing position to clean the other four surfaces. After completion, the first clamping part 2 turns over to the intersection with the track of the second clamping part 3, and the second clamping part 3 clamps the processed surface, and turns over to the processing position to process the remaining two surfaces. clean up. All surfaces of the workpiece can be cleaned at one time on the workbench, which solves the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com