Active cable pay-off device

A pay-off device and active technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of cable accumulation, easily damaged cables, etc., and achieve the effect of protecting cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

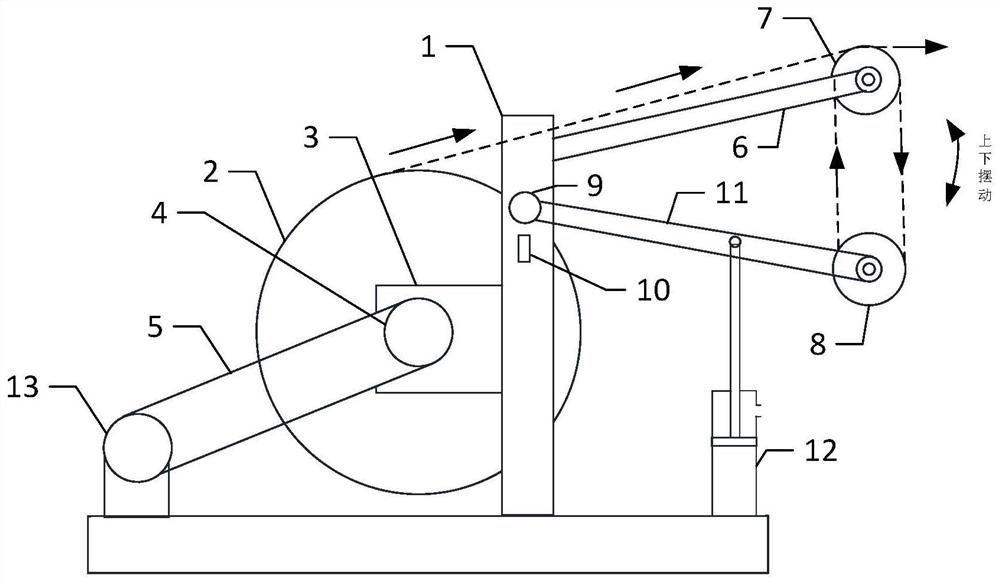

[0031] Specific implementation mode one: refer to Figure 1 to Figure 3 Specifically explain this embodiment, the active cable pay-off device described in this embodiment, in this embodiment, the device includes a wire reel 2, a wire reel support device, a wire reel rotation speed control device and a cable tension change device,

[0032] The reel support device is used to support the reel,

[0033] The reel rotation speed control device comprises a cam mechanism 9, a displacement sensor 10 and a controller,

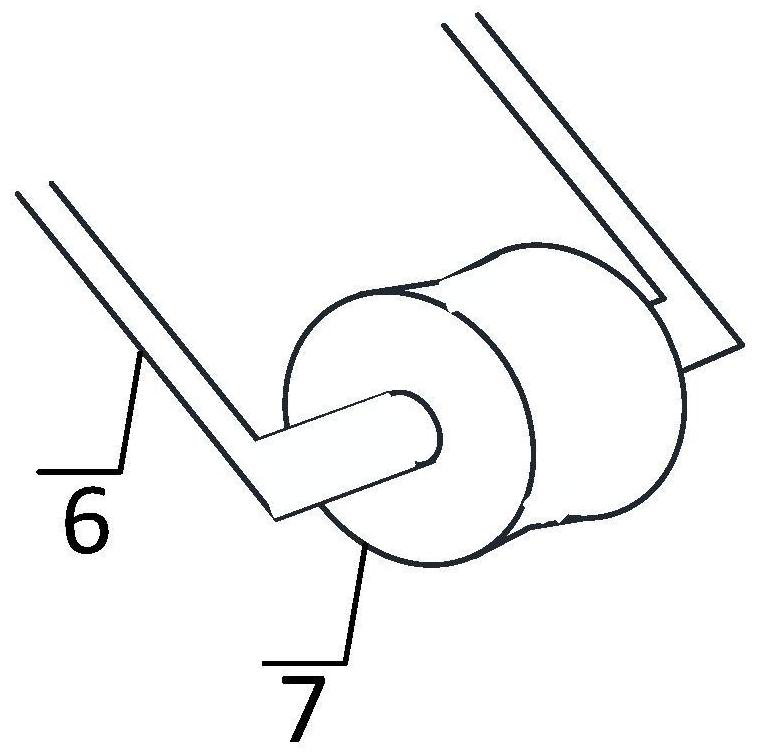

[0034] The cable tension changing device includes No. 1 U-shaped bar 6, No. 2 U-shaped bar 11, cylinder 12, fixed guide wheel 7 and swing guide wheel 8,

[0035] The fixed guide wheel 7 is sleeved on the horizontal bar of the No. 1 U-shaped bar 6, and the two free ends of the No. 1 U-shaped bar 6 are fixedly connected on the two supporting legs of the reel support device.

[0036] The swing guide wheel 8 is sleeved on the horizontal bar of the No. 2 U-shaped bar 11. O...

specific Embodiment approach 2

[0042] Specific embodiment 2: This embodiment is a further description of the active cable pay-off device described in specific embodiment 1. In this embodiment, the reel support device includes a base, a reel support frame 1, a reel, and a reel connection Component 3, wide belt pulley 4, synchronous belt 5, end cover, motor end pulley 13 and motor,

[0043] The reel support frame 1 is fixed on the base, and the two inner walls of the reel support frame 1 are respectively connected with a reel connection assembly 3, and the reel connection assembly 3 has a reel hole, and the reel is inserted into the reel 2. The two ends are respectively inserted into the reel holes, and the reel 2 is supported. One end of the reel is covered with an end cap, and the reel connection assembly 3 is limited on the reel. The other end of the reel is covered with a wide belt pulley 4, and the base is provided with a motor. A motor end pulley 13 is sleeved on the motor output shaft, and a timing bel...

specific Embodiment approach 3

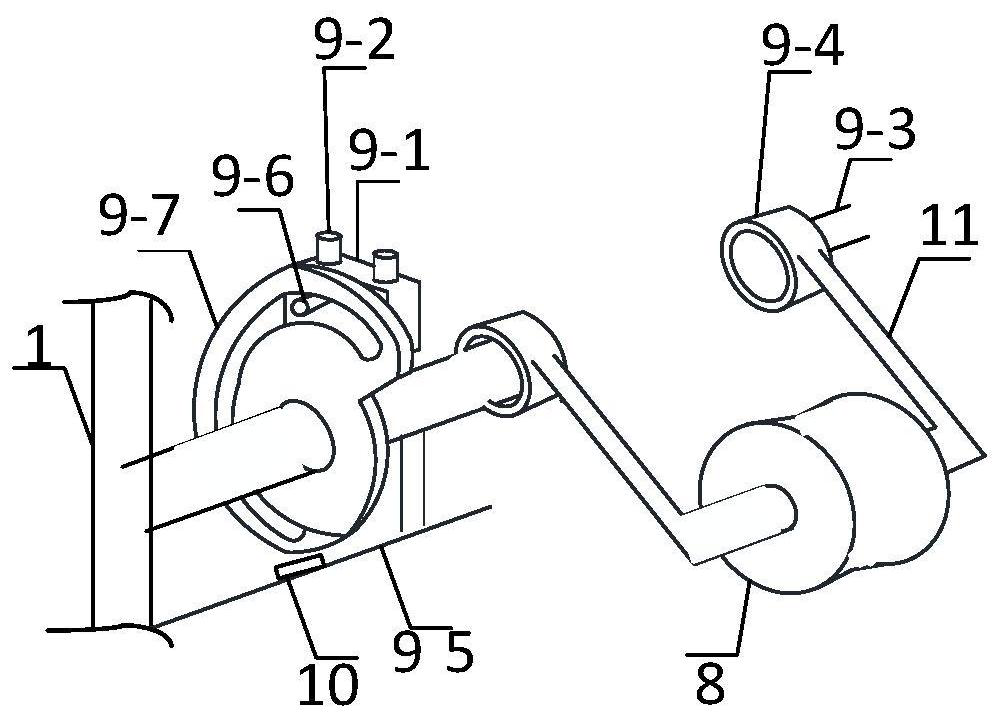

[0046] Specific embodiment 3: This embodiment is a further description of the cable active pay-off device described in specific embodiment 1. In this embodiment, the cam mechanism 9 includes a cam 9-7, a slider 9-1, and a pole 9 -2, connecting shaft 9-3, sleeve 9-4, connecting plate 9-5 and slide bar 9-6,

[0047] The two inner walls of the reel support frame 1 are symmetrically provided with through holes, and the two connecting shafts 9-3 stretch out from the through holes respectively, and the ends of the two connection shafts 9-3 exposed on the outer side walls of the reel support frame 1 are both connected. Covered with nuts, the other ends of the two connecting shafts 9-7 are respectively fixedly sleeved with a sleeve 9-4,

[0048]On the two sleeves 9-4, two free ends of No. 2 U-shaped rods are fixedly connected, and on the connection shaft 9-3 between the inner side wall of the reel support frame 1 and a sleeve 9-4, there is a Cam device 9-7, connecting plate 9-5 is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com