A method for controlling a food processing machine

A technology of food processing machine and control method, which is applied in the direction of electrical program control, program control in sequence/logic controller, kitchen utensils, etc., and can solve the problems of working environment pollution, inability to completely discharge slurry, overflowing slurry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

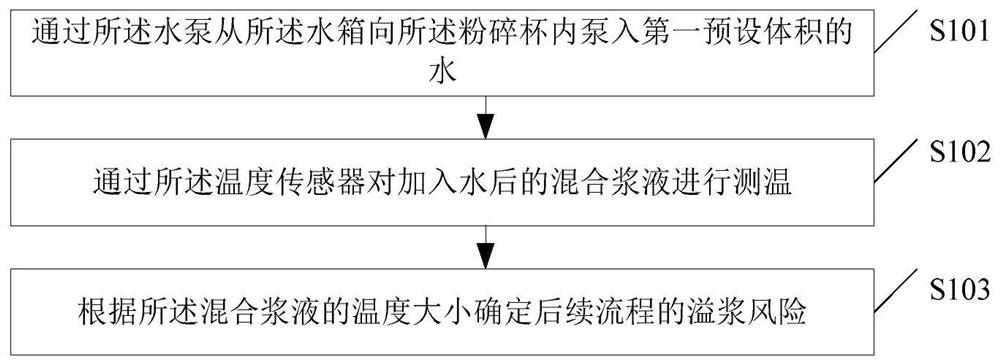

[0039] An embodiment of the present invention provides a control method for a food processor, the food processor may include: a motor, a crushing cup, a temperature sensor and a water tank, the water tank is connected to the crushing cup through a pipeline, and the pipeline There is a water pump in it; if figure 1 As shown, the method may include: the entire pulping process includes one or more pulpings, and after any pulping is completed, enter the following anti-overflow program S101-S103:

[0040] S101. Pump a first preset volume of water from the water tank into the crushing cup through the water pump;

[0041] S102. Measure the temperature of the mixed slurry after adding water through the temperature sensor;

[0042] S103. Determine the slurry overflow risk of the subsequent process according to the temperature of the mixed slurry.

[0043] In an exemplary embodiment of the present invention, the water in the water tank may have room temperature (or water lower than a ...

Embodiment 2

[0053] On the basis of the first embodiment, this embodiment provides an embodiment plan of the anti-flooding pulp program that determines which processing flow to enter after a pulp discharge is completed according to the size of the current pulping capacity.

[0054] In an exemplary embodiment of the present invention, the method may further include: according to the size of the current pulping capacity, determine which anti-flooding procedure of the treatment process to enter after a pulp discharge is completed.

[0055] In an exemplary embodiment of the present invention, the processing procedure may include: a subsequent pulping procedure and a cleaning procedure; the temperature threshold may include: a pulping temperature threshold and a cleaning temperature threshold.

[0056] In an exemplary embodiment of the present invention, according to the size of the current pulping capacity, the anti-flooding procedure for determining which processing flow to enter after a pulp ...

Embodiment 3

[0062] On the basis of the second embodiment, this embodiment provides a specific embodiment of the anti-overflow program that enters the subsequent pulping process after the first pulping is completed.

[0063] In an exemplary embodiment of the present invention, when the current pulping capacity is greater than 600ml, there is a greater risk of pulp overflow in one discharge pulping, so multiple discharges can be used for pulping, but in order to optimize the entire The process time can be pulped twice.

[0064] In an exemplary embodiment of the present invention, after the first pulp discharge is completed, a water pump may be used to pump cold water with a volume V (that is, the first preset volume V) in the water tank and inject it into the crushing cup. R (that is, the first preset rotational speed R) rotates and stirs for a duration of t (that is, the first preset duration of t), fully mixes the residual slurry and cold water, and measures the temperature T of the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com