Poaching-resistant powder coating composition

A technology of powder coatings and compositions, applied in the direction of powder coatings, polyester coatings, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

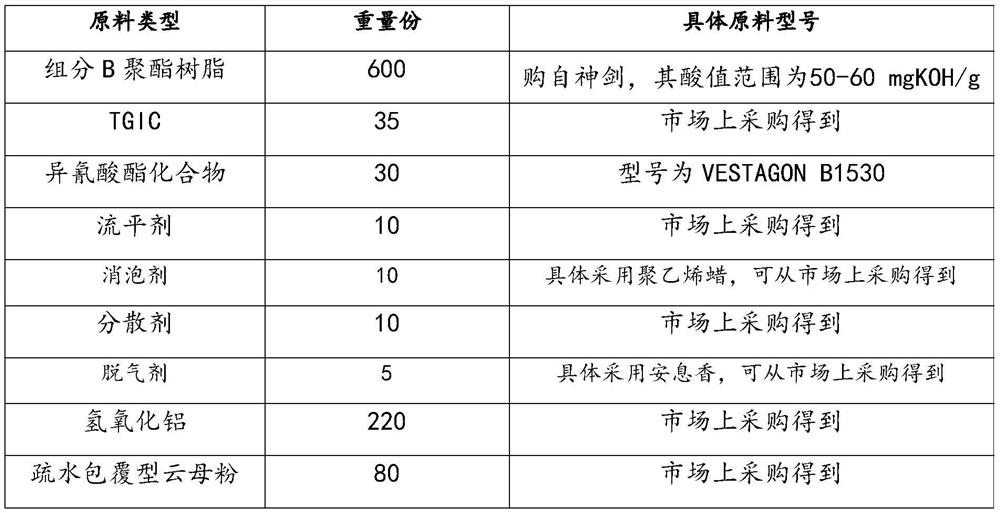

[0026] Embodiment 1: a kind of boil-resistant powder coating composition, comprise the dry mixed mixture of component A powder coating and component B powder coating, the weight ratio between component A powder coating and component B powder coating is 1: 1; Among them, please refer to the following table 1a for the formulation raw materials of component A powder coating, and please refer to the following table 1b for the formulation raw materials of component B powder coating:

[0027] Formulation of component A powder coating in table 1a embodiment 1

[0028] Raw material type parts by weight Specific raw material model The first component A polyester resin 300 Available from DSM with an acid value in the range of 30-40 mgKOH / g Second component A polyester resin 300 Purchased from Excalibur, its acid value ranges from 18-24 mgKOH / g TGIC 35 purchased from the market Isocyanate compound 30 The model is VESTAGON B1530 leveling ag...

Embodiment 2

[0034] Embodiment 2: A kind of boiling-resistant powder coating composition, all the other technical schemes are the same as embodiment 1, the difference is that in this embodiment 2, the weight ratio between component A powder coating and component B powder coating is 1 :3.

Embodiment 3

[0035] Embodiment 3: A kind of boiling-resistant powder coating composition, all the other technical schemes are the same as embodiment 1, the difference is that in this embodiment 3, the weight ratio between component A powder coating and component B powder coating is 3 :1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com