Bridge pier body anti-pollution system for creeping formwork construction

An anti-pollution, pier body technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of grout leakage in newly poured sections, affect the image of the project entity, and pollute the bridge pier body, etc., to achieve convenient installation and good promotion and application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

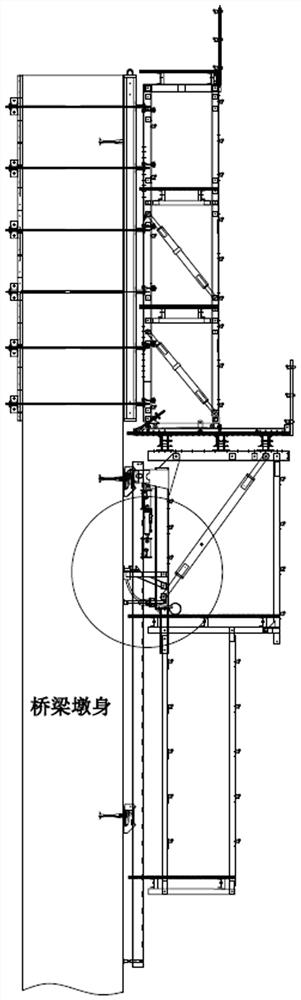

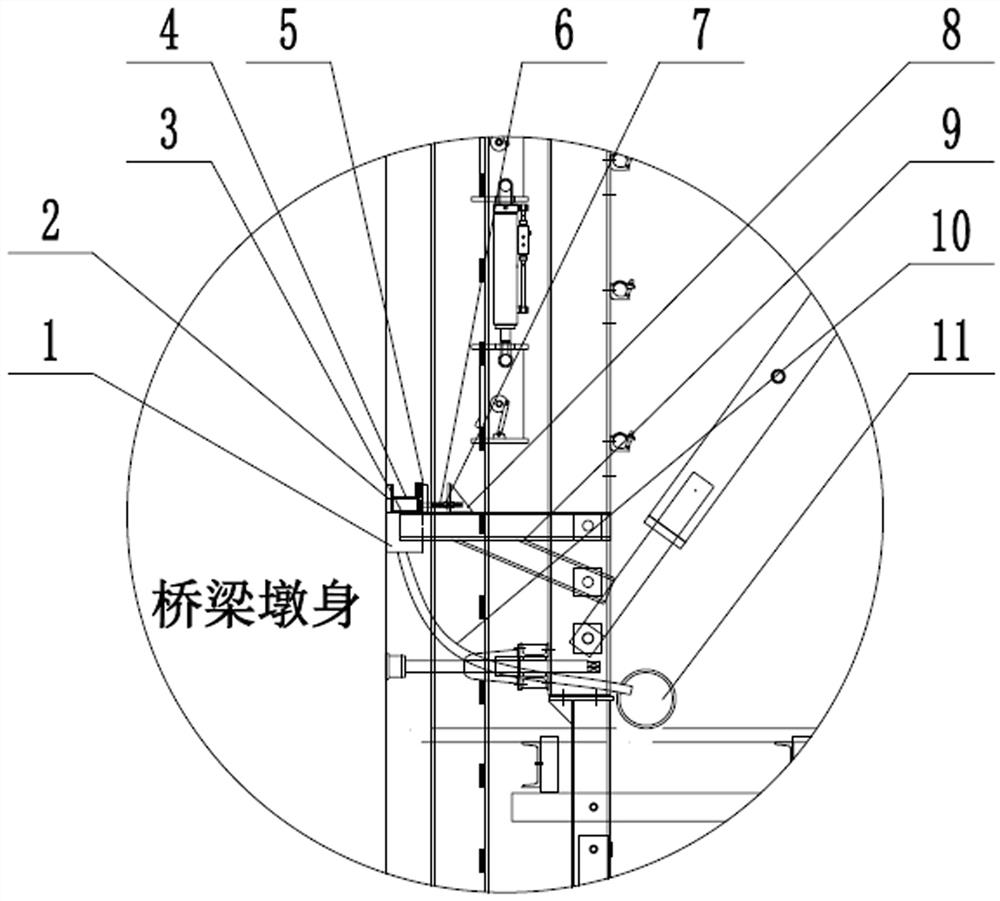

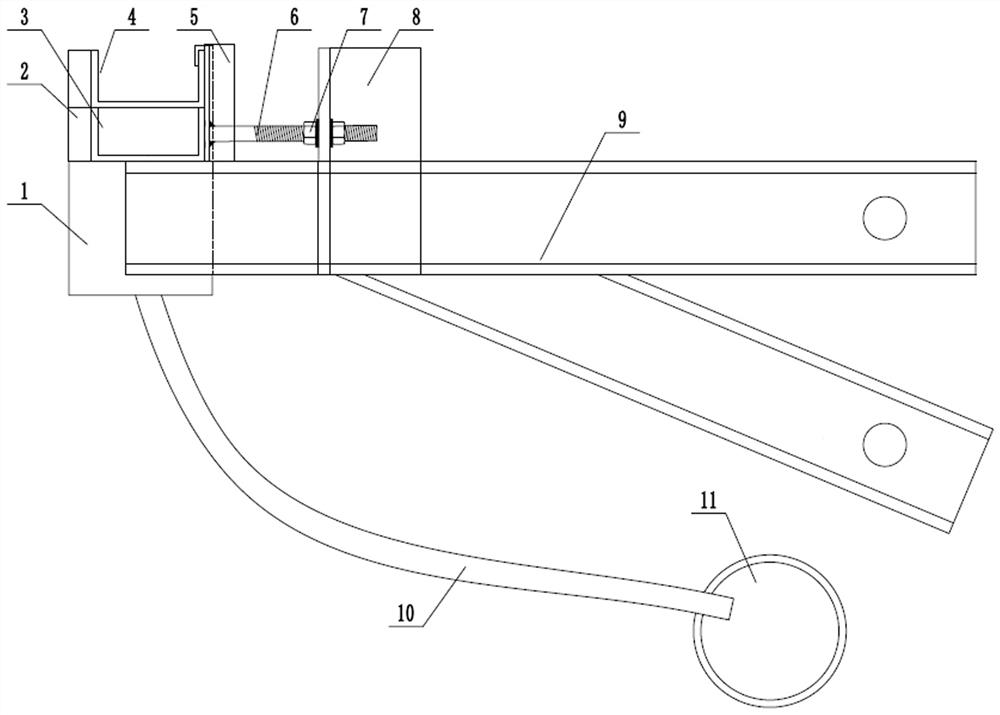

[0027] A bridge pier body anti-pollution system for climbing formwork construction, which includes a sump 3, a connection sump 4, a sump bracket 9, a main water pipe 11 and a top pressure device, and the sump bracket 9 is fixed on On the vertical pole of the load-bearing tripod of the climbing formwork, the water collection tank bracket 9 is firmly connected with the vertical pole of the load-bearing tripod of the climbing formwork with bolt fasteners; the water collection tank 3 is erected on the water collection tank bracket 9, and the water collection tank 3 surrounds the bridge pier It is erected around, and the sump 3 around the bridge pier body has a plurality of connection ports; the two ends of the sump 4 of the connection port are respectively erected on the sump 3 at both ends of the connection port; The water collection basket 1 of cement slurry and curing water; the bottom of the water collection basket 1 is connected with a branch water pipe 10, and the branch wate...

Embodiment 2

[0029] A bridge pier body anti-pollution system for climbing formwork construction, which includes a sump 3, a connection sump 4, a sump bracket 9, a main water pipe 11 and a top pressure device, and the sump bracket 9 is fixed on On the vertical pole of the load-bearing tripod of the climbing formwork, the water collection tank bracket 9 is firmly connected with the vertical pole of the load-bearing tripod of the climbing formwork with bolt fasteners; the water collection tank 3 is erected on the water collection tank bracket 9, and the water collection tank 3 surrounds the bridge pier Erected around, the water collection tank 3 around the bridge pier body has a plurality of connection ports; All are made of channel steel. A water collecting basket 1 for connecting cement slurry and curing water flowing from the connecting port is installed at the connection port; the bottom of the water collecting basket 1 is connected with a branch water pipe 10, and the branch water pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com