Photovoltaic power generation and mechanical draft cooling tower combined energy-saving and efficiency-improving method and device

A technology of mechanical ventilation and photovoltaic power generation, applied in photovoltaic power generation, photovoltaic modules, water shower coolers, etc., can solve the problems of high cost of distributed photovoltaic power generation, high energy consumption of equipment operation, high outlet water temperature, etc., and increase photovoltaic power generation capacity , Increased operating costs, increased water temperature difference between entering and leaving the tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

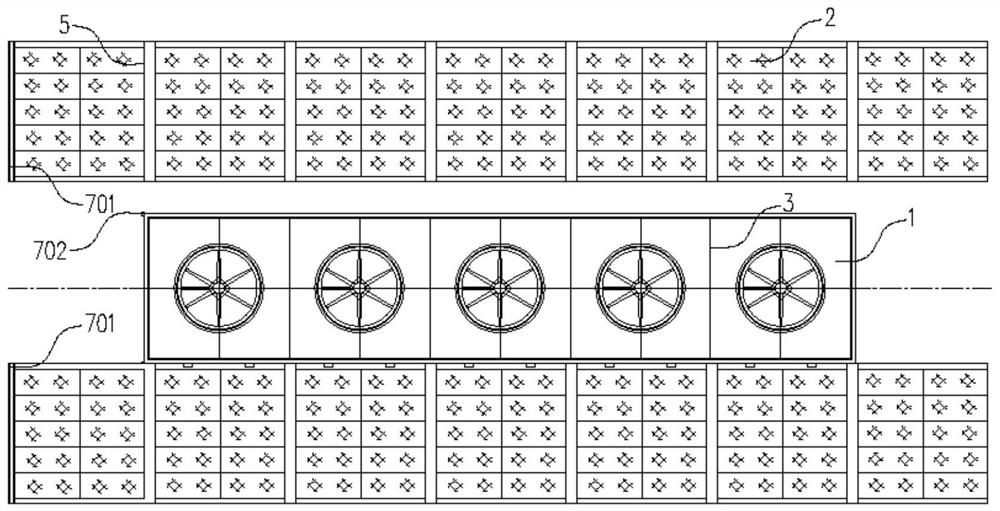

[0058]Such asFigure 1 - Figure 3 As shown, the mechanical ventilation cooling tower 1 is divided into two types and circular shapes in the shape, and there are three types of cross-flow and countercurrent types, and the solar panel 2 for photovoltaic power generation is usually in accordance with the material, packaging of the solar cell. Classification of type, transparency, and combination with buildings.

[0059]The energy saving and efficiency method of the combination of photovoltaic power generation and mechanical ventilation and cooling tower includes the following steps:

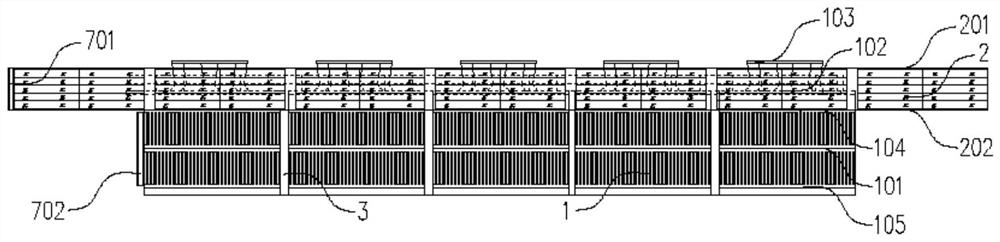

[0060]S1, in the vicinity of the mechanical ventilation cooling tower 1 inlet 101, with the column top 102, etc., mounting a group solar panel 2, the solar panel 2 in the air supply direction is 2-6 meters, using the installation of the sun The battery panel 2 is shade the space near the mechanical ventilation cooling tower 1 inlet 101, wherein the solar panel 2 is assembled from the same components into a array...

Embodiment 2

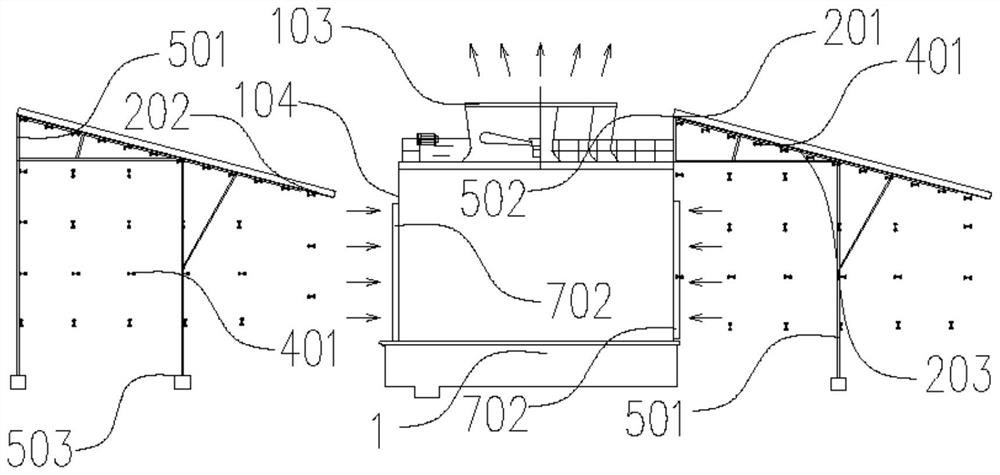

[0087]The present invention provides an energy saving and efficiency device that combines photovoltaic power generation and mechanical ventilation cooling tower, such asFigure 1 - Figure 4As shown, including the mechanical ventilation cooling tower 1, the distributed photovoltaic power generation device 5, the spray cooling device 4, the water supply device 6, and the automatic control device 9, wherein the distributed photovoltaic power generation device 5 includes a plurality of sets of solar panels 2, mounting bracket 501. , Inverter, supply and distribution circuit, etc., solar panel 2 is disposed in the vicinity of the air outlet 101 of the mechanical ventilation cooling tower 1, and the sunshade width of the solar panel 2 in the air supply direction is in the vicinity of the venting tower of the mechanical ventilation cooling tower 1. 2-6 meters, here the solar panel 2 is disposed above the air inlet region of the air inlet 101 of the mechanical ventilation cooling tower 1.

[00...

Embodiment 3

[0125]Such asFigure 1 - Figure 5 As shown, when the tower line 3 of the mechanical ventilation cooling tower 1 is two rows or two rows, the mounting bracket 501 is located between the two rows of column 3, and the upper end 502 utilizes the mechanical ventilation cooling tower 1 South side. The air inlet 101 is fixed to the wind along 104 and extend upward does not exceed the height of the air cylinder 103, and the mounting bracket 501 lower end 503 is fixed in the mechanical ventilation cooling tower 1 mounting ground, and the horizontal distance of the north side of the south side tower 3 is about 1.5. -2.5 m, and the array of solar panels 2 after installation should avoid the tower body and the wind cylindrical 103 of the tower line 3 to block the sun, and the mounting height is not lower than the north side of the southern side of the southern side airhead 101. Windy wind along 104.

[0126]As an alternative embodiment, when the spacing between the two rows 3 is large, the solar pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com