A composite cooling tower

A cooling tower and composite technology, applied in the field of cooling tower devices and composite cooling towers, can solve the problems of inability to meet process requirements alone, scaling on the surface of heat exchange tubes, affecting heat transfer effects, etc., and achieve a wide range of application markets and prospects. , The effect of saving water consumption and prolonging heat exchange time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

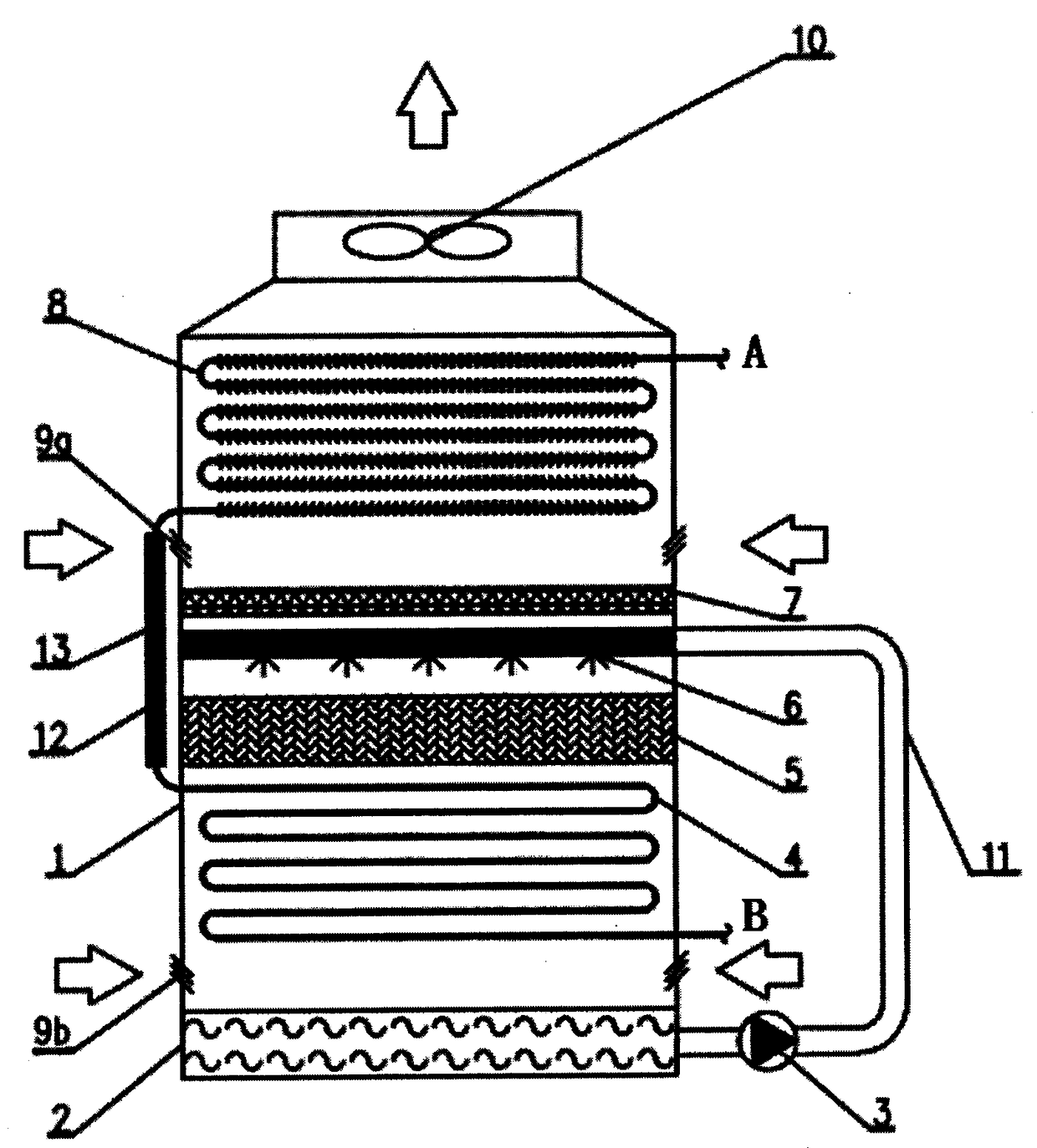

[0020] Such as figure 1 As shown, the composite cooling tower main box 1, water tank 2, spray water circulation pump 3, bare tube bundle 4, filler 5, spray equipment 6, water retaining plate 7, finned tube bundle 8, louvers 9a, louvers 9b, The induced draft fan 10, the circulating water pipe 11, the coil connecting section 12, the thermal insulation material 13 and other components are composed. In the figure, A is the hot water inlet, B is the hot water outlet, the directions of the arrows on both sides of the box body 1 are the air intake directions of the shutters 9a and 9b, and the directions of the arrows on the top of the box body 1 are the air outlet directions.

[0021] The box body 1 is made of glass fiber reinforced plastic material in the form of a cuboid, fixed on the ground by bolts, and easy to disassemble. The wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com